Vertically grounding down-leading method for center of composite material tower and tower thereof

A technology of composite materials and grounding down conductors, applied in the direction of connecting contact materials, spatial arrangement/configuration of cables, electrical components, etc., can solve the problem of affecting the lightning protection effect of composite material towers, affecting the anti-fouling of lines, and reducing the transmission corridor Width and other issues to achieve the effect of avoiding inconvenience, enhancing insulation strength, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

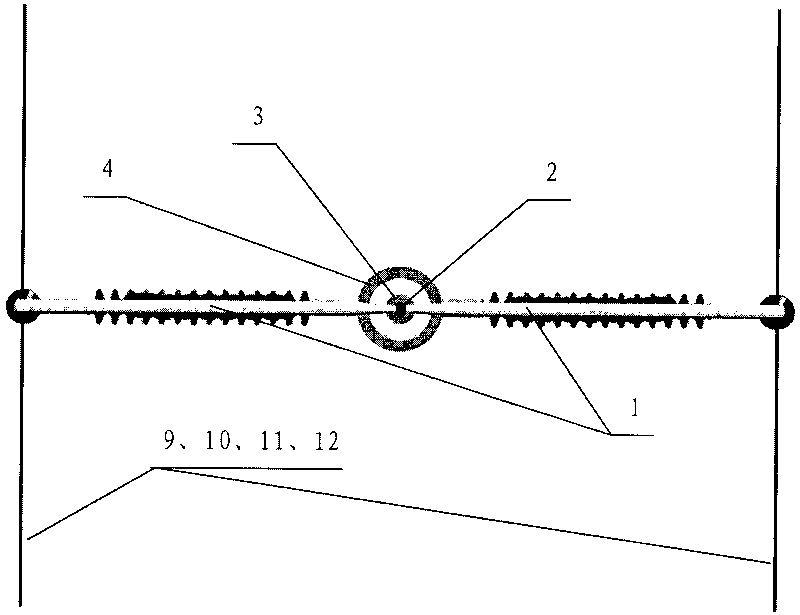

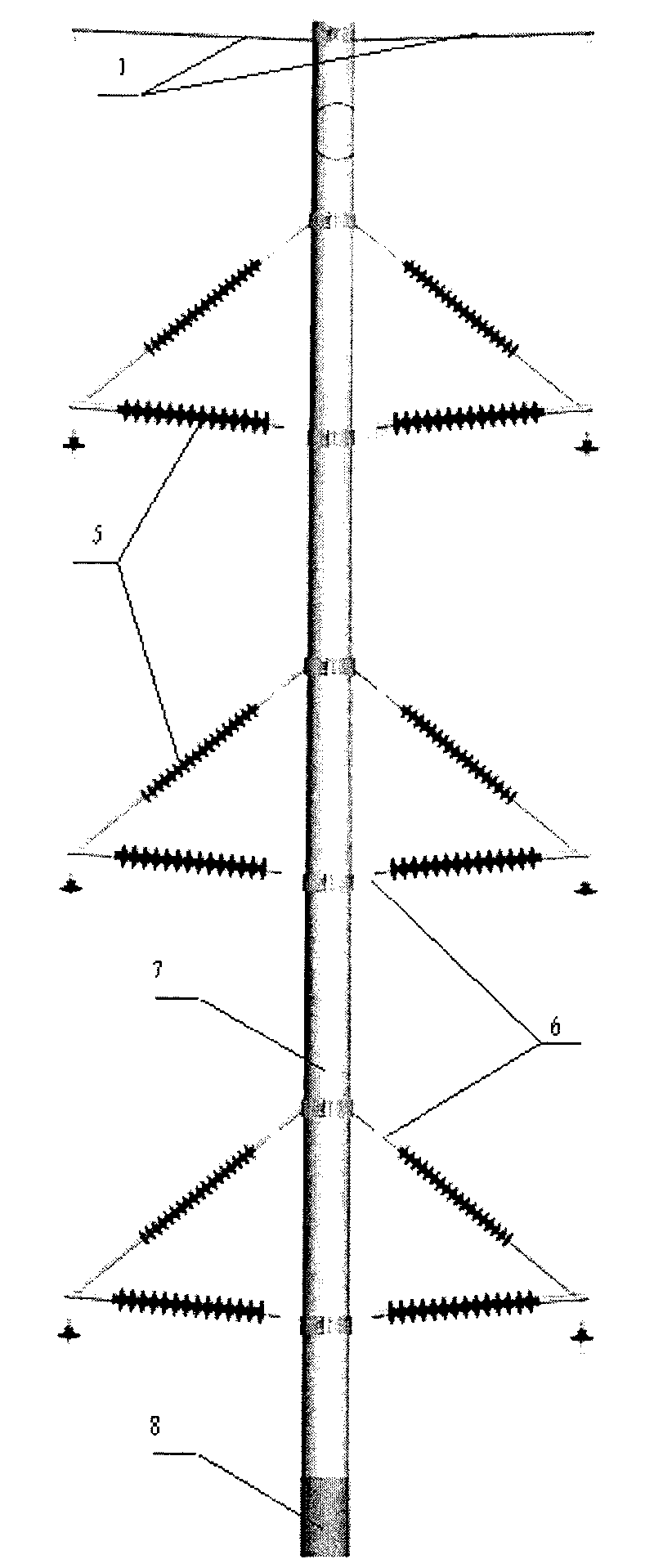

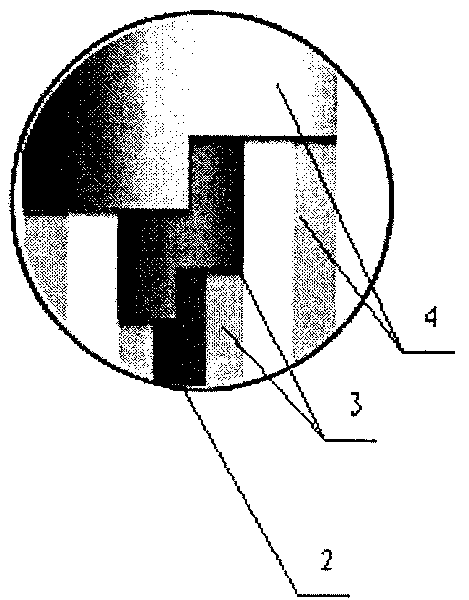

[0028] figure 1 , 2 , Mark description in 4: 1-ground wire crossarm, 2-ground downconductor, 3-ground downconductor insulation cladding, 4-composite material tower wall insulation layer, 5-composite insulator, 6-composite insulator Connecting and supporting parts, 7-tower body part of tower head, 8-tower body lower part, 9-ground wire, 10-upper phase wire, 11-middle phase wire, 12-lower phase wire, 13-flashover point, 14- Flashover point and grounding down conductor electrical connection parts.

[0029] The ground cross arm 1 in the present invention is made of metal material, and the ground down conductor 2 is drawn out from the center of the ground wire cross arm 1, and the ground down conductor 2 is vertically connected to the ground from the center of the composite material tower. Part 8 under the body is a steel pipe, and the grounding downconductor 2 can be directly connected to the steel pipe for grounding.

[0030] Since the tower body part 7 of the tower head of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com