System and method for on-site point-by-point calibration of brightness and chrominance of the whole screen of LED display screen

A technology of LED display and calibration system, applied in static indicators, instruments, etc., can solve the problems of uneven color, difficult implementation, low adjustment efficiency, etc., to achieve uniform pixels, reduce processing costs, and ensure the effect of correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the principles of the system and method of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

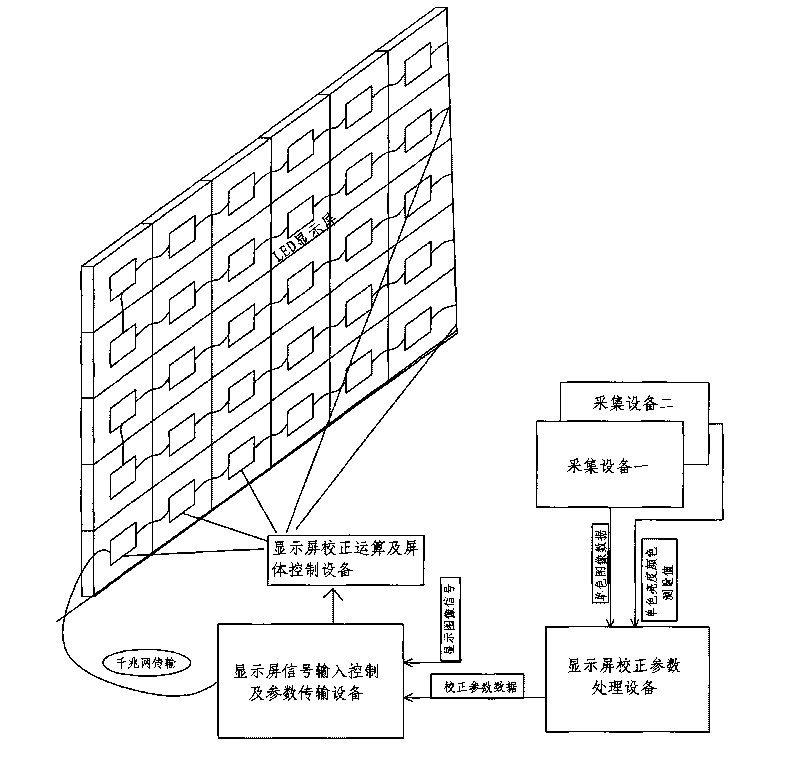

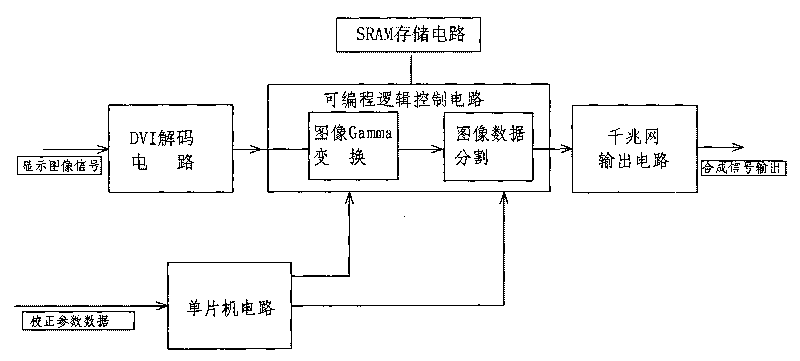

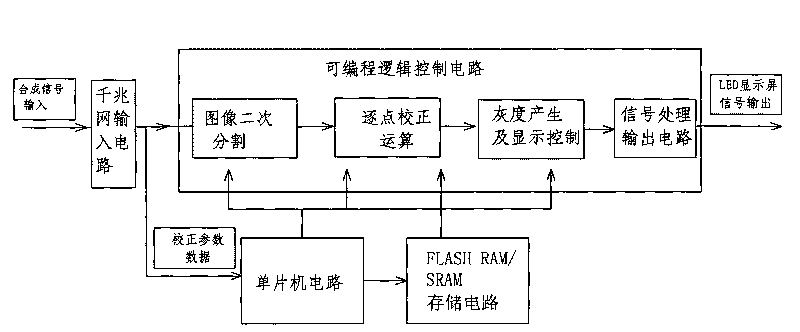

[0035] as attached figure 1As shown, the system of the present invention includes LED display optical parameter acquisition equipment, display calibration parameter processing equipment, display signal input control and parameter transmission equipment, and display calibration calculation and screen body control equipment.

[0036] Wherein, described on-the-spot LED display screen optical parameter acquisition equipment is divided into two parts: acquisition equipment one selects to be used for acquiring the single-lens reflex digital camera of display screen display red, green, blue monochrome, original LED luminance chromaticity relative difference image information; Acquisition Device 2 selects the bright color measuring ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com