Three-arm hydraulic wagon drill and tunnel drilling and grouting construction method

A technology of drilling grouting and rock drilling jumbo, which is applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc. It can solve the problems of time-consuming, laborious and low efficiency, and achieve the advantages of advanced construction technology, convenient and fast disassembly, and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better illustrate the present invention, give examples as follows:

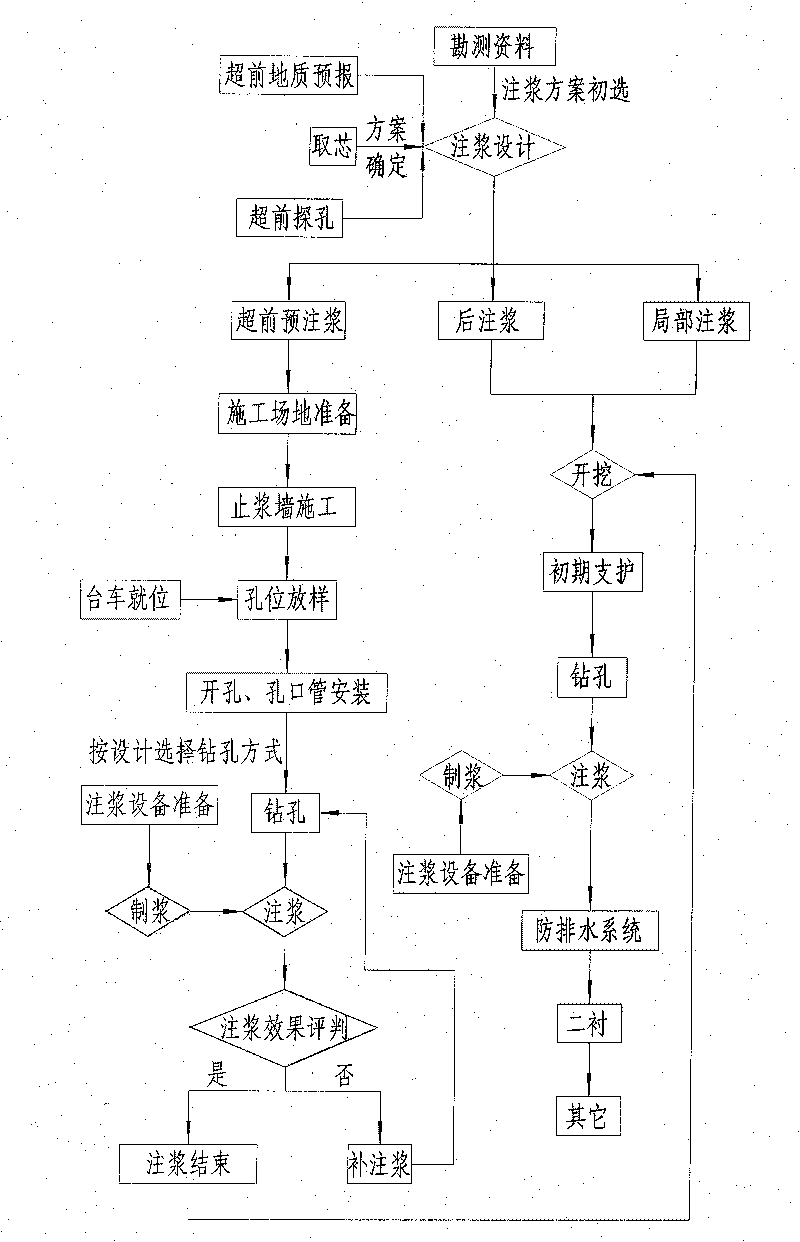

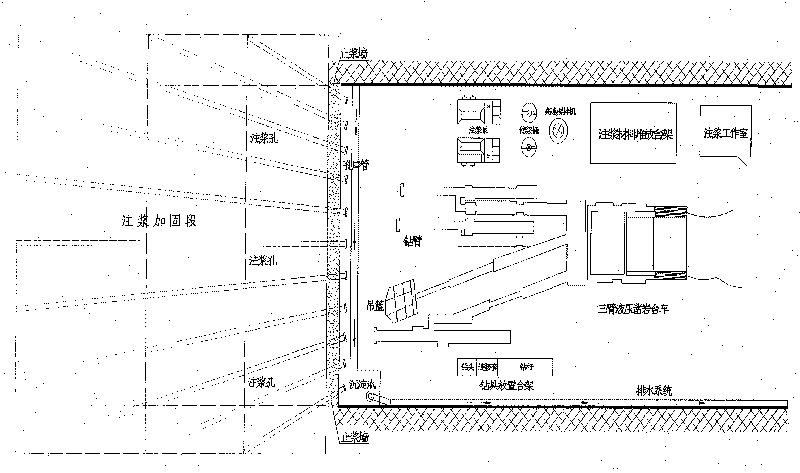

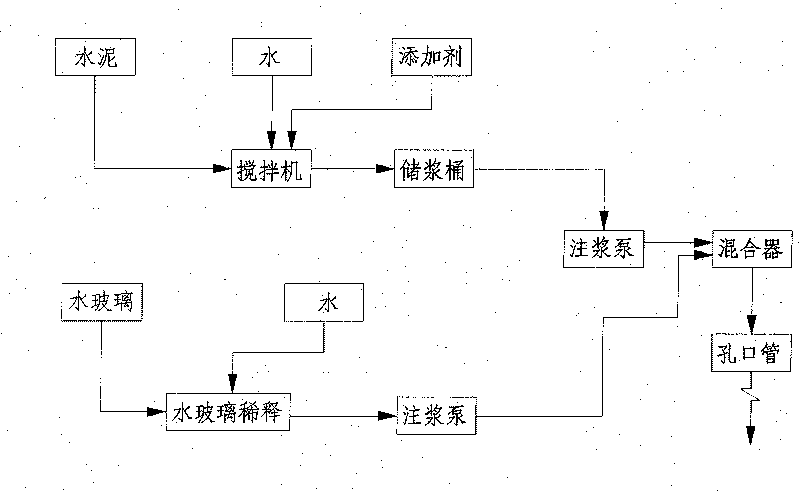

[0032] After a subsea tunnel enters the sea area, the geological conditions are complex and changeable. The bedrock of the tunnel is mainly volcanic breccia tuff with crystalline debris, partially sandwiched with tuff, and there are many diabase veins and quartz syenite veins intruded. The integrity of the body and the thickness of the weathered zone vary greatly, and most of them are fragmented to mosaic broken structures. The impermeability of the surrounding rock is easy to deteriorate when it is loose and deformed, and seepage deformation damage may occur, causing geological disasters such as mud gushing, water gushing, and collapse. Therefore, in tunnel excavation construction, advanced pre-grouting is the key link to ensure construction safety and the top priority of the work. "Lining" construction deployment prerequisites, see the specific flow chart figure 2 shown. The advanced p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com