Method for preparing modified bauxite catalyst in ozone heterogeneous catalysis water treatment technology

A technology of heterogeneous catalysis of water and heterogeneous catalysis, which is applied in the field of preparation of catalysts of ozone heterogeneous catalysis water treatment technology system, can solve the problems of low catalysis efficiency and high cost, and achieves improved utilization efficiency, increased generation rate and quantity, and improved production efficiency. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

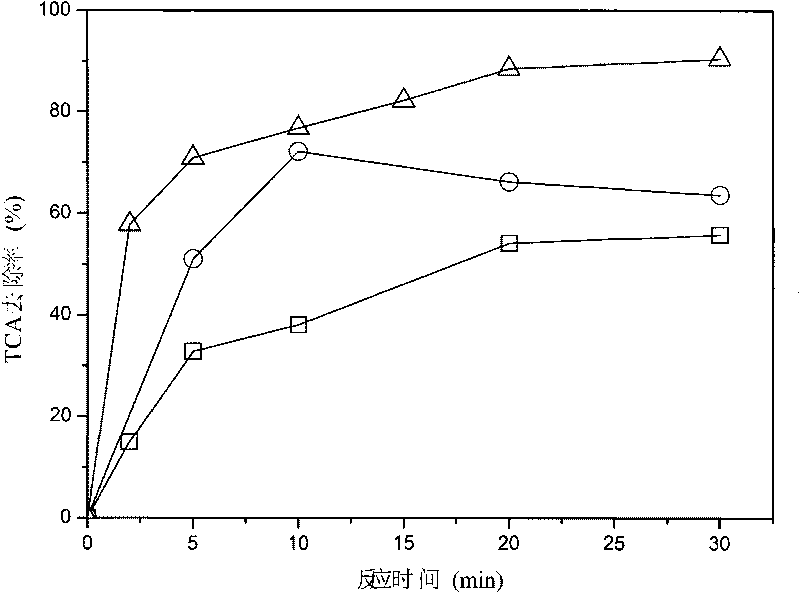

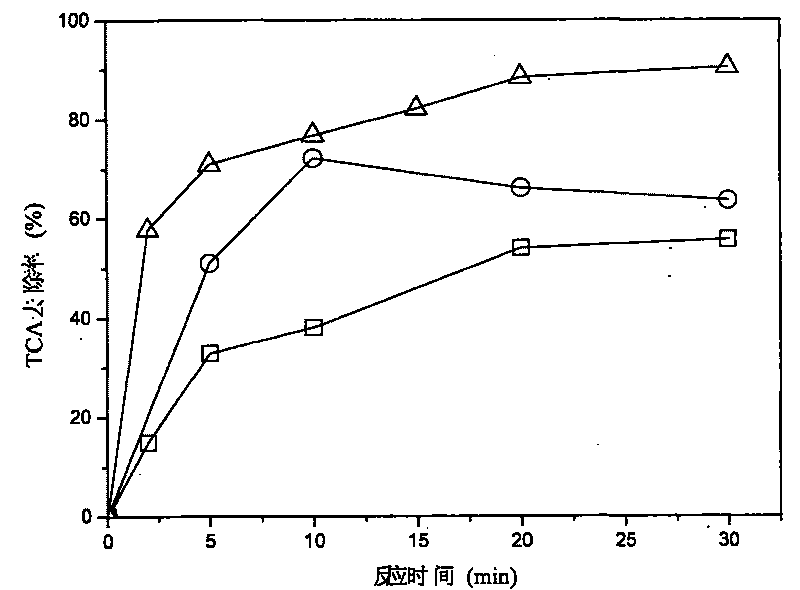

[0010] Specific implementation mode 1: In this implementation mode, the iron-modified bauxite ozone heterogeneous catalytic water treatment technology system catalyst modification background is natural bauxite, and the main components are γ-AlOOH and γ-Al 2 o 3 .

specific Embodiment approach 2

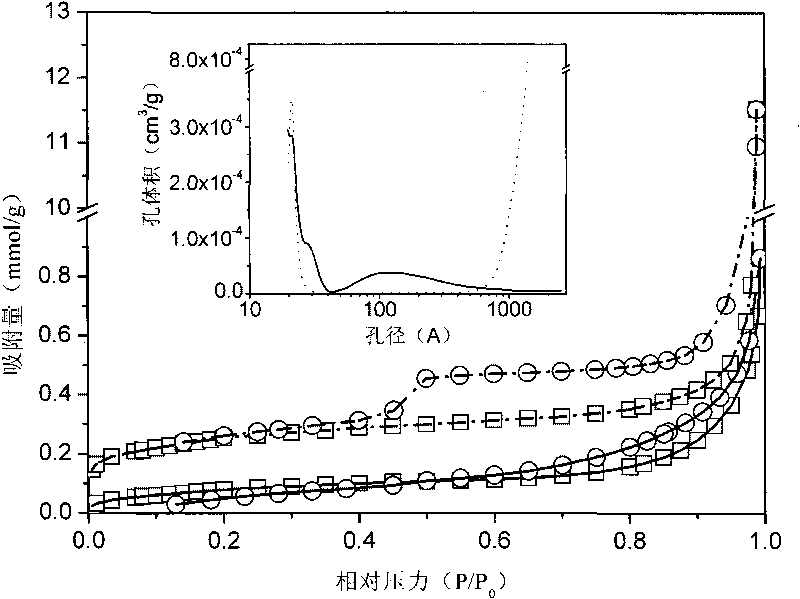

[0011] Specific embodiment two: the preparation method of iron-modified bauxite ozone heterogeneous catalytic water treatment system catalyst is realized according to the following steps: (1) preparing Fe(NO 3 ) 3 Modified solution, the concentration level is 0.196~0.206mol / L, and stored at room temperature; (2) After cleaning 5g of natural bauxite, dry it at a temperature of 68~72°C for 30~35h; (3) Put the above Then soak in 100mL of the above solution, shake in a steam bath at 22-28°C for 14-18 hours; then age at room temperature for 22-26 hours; then pour off the supernatant, and dry the remaining suspension at 65-75°C for 26 hours ~30 hours to obtain dry powder, and grind the dry powder to fine particles for later use; (4) place the above fine particles in a high-temperature muffle furnace for high-temperature calcination at a calcination temperature of 590-610°C and a calcination time of 3.5-4.5 hours to obtain Dry powder: Grind and sieve the above dry powder to select a...

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the natural bauxite in the step (2) is in a massive form. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com