Method for growing ZnS single-crystal nanowire bundle

A single-crystal nano, solvothermal technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the high requirements of reaction time, reaction temperature, concentration, complex operation process of soft template method, ZnS nanowires Complex growth and other problems, to achieve the effect of easy promotion, uniform morphology, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

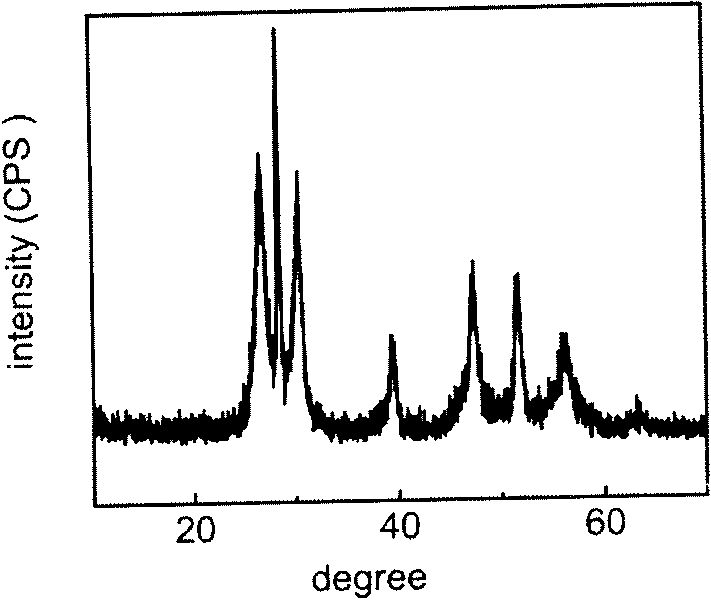

[0021] With polyvinylpyrrolidone (PVP) 0.3g as surfactant, it is added in the reactor that fills 40ml hydrazine hydrate, and puts into magnetic sub-stirring; Then zinc acetate and thiourea are mixed with 1 (0.220g): 4 ( 0.304g) in the mol ratio was added to the reactor successively, and stirred with a magnet. After stirring well, the reaction kettle was put into an oven at 160° C. for 48 hours. After washing, the product was dried in a vacuum oven at 60° C. for 6 h to collect the product. The results of XRD analysis showed that the obtained product was ZnS with wurtzite structure.

Embodiment 2

[0023] With polyvinylpyrrolidone (PVP) 0.3g as surfactant, it is added in the reactor that fills 40ml hydrazine hydrate, and puts into magnetic sub-stirring; Then zinc acetate and thiourea are mixed with 1 (0.220g): 4 ( 0.304g) in the mol ratio was added to the reactor successively, and stirred with a magnet. After stirring sufficiently, the reaction kettle was placed in an oven at 160° C. for 36 hours. After washing, the product was dried in a vacuum oven at 60° C. for 6 h to collect the product. The results of XRD analysis showed that the obtained product was ZnS with wurtzite structure.

Embodiment 3

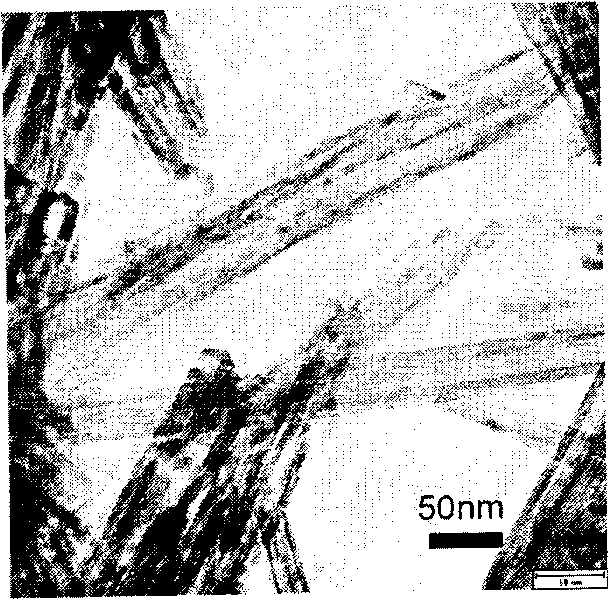

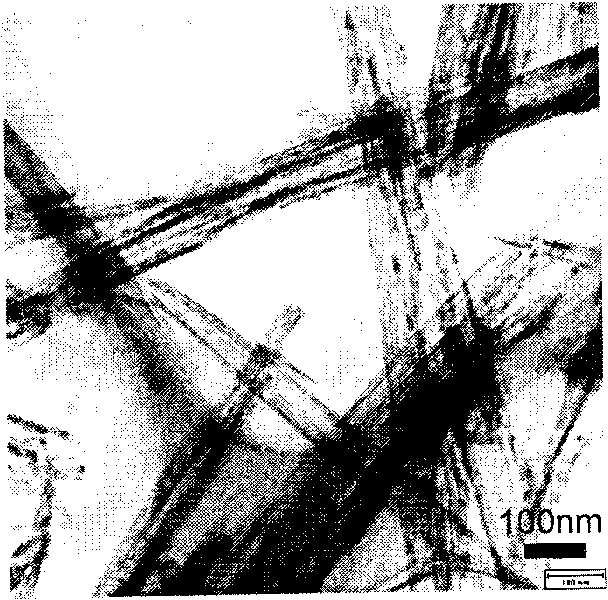

[0025] With polyvinylpyrrolidone (PVP) 0.3g as surfactant, it is added in the reactor that fills 40ml hydrazine hydrate, and puts into magnetic sub-stirring; Then zinc acetate and thiourea are mixed with 1 (0.220g): 4 ( 0.304g) in the mol ratio was added to the reactor successively, and stirred with a magnet. After stirring well, the reaction kettle was put into an oven at 160° C. for 24 hours. After washing, the product was dried in a vacuum oven at 60° C. for 6 h to collect the product. The XRD analysis results show that the obtained product is ZnS with wurtzite structure, such as figure 1 shown. The shape of the ZnS nanostructure is regular, the average particle size is about 10-20nm, and its transmission electron microscope picture is as follows figure 2 and image 3 , high-resolution transmission electron microscope pictures such as Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com