Manufacturing method of integrated square fire-resisting damper valve buckle body molding and rolling forming device thereof

A production method and roll forming technology, which is applied in the direction of metal processing equipment, etc., can solve the problems of deformation of the processing size at the joint, increase in processing cost, increase in production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

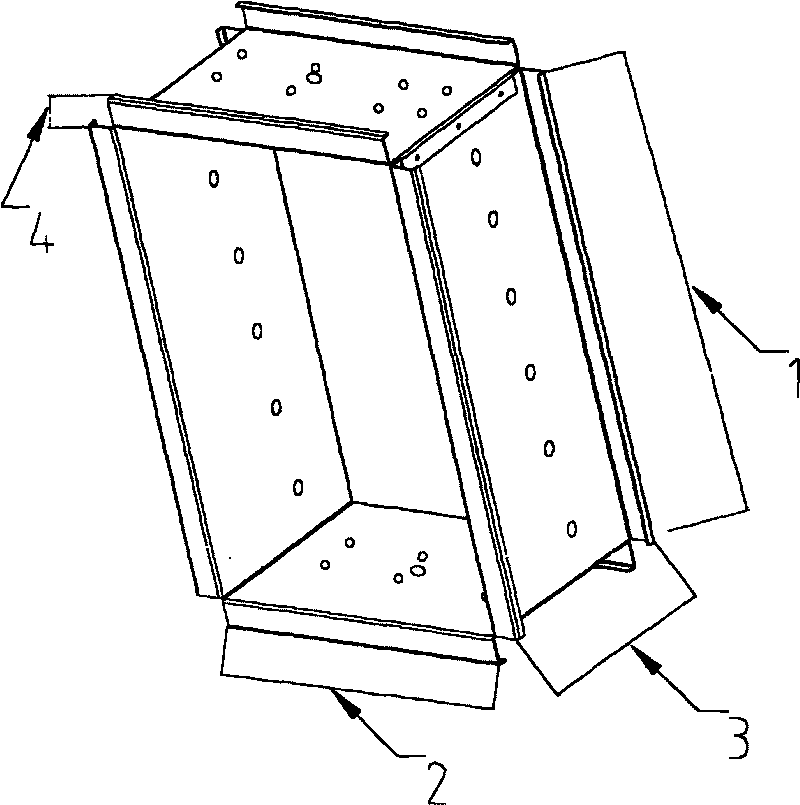

[0053] The production method of the 400*300*250*36 fire damper frame. The legend and dimensions are as follows:

[0054] Logo 1 size is 400 (size W determined by customer),

[0055] Logo 2 size is 300 (size H determined by customer),

[0056] The size of logo 3 is 250 (relatively fixed size L),

[0057] The size of sign 4 is 36 (relatively fixed size F), see attached figure 1 .

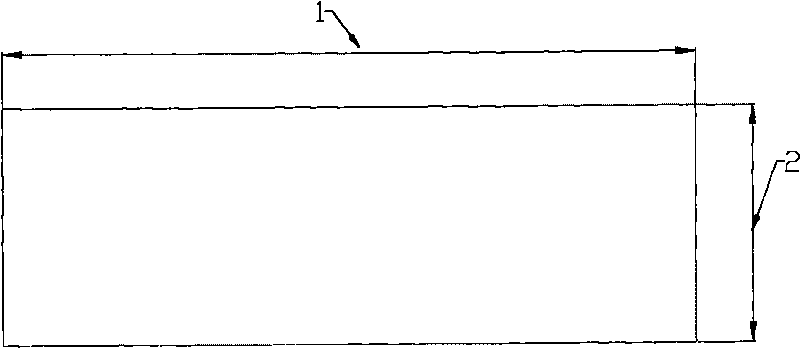

[0058] 1. Cutting board (see attached figure 2 )

[0059] A whole board is blanked with a shearing machine according to the size ordered by the valve body, and cut into a rectangular board. The size of logo 1 is (W-0.16)+(H+0.68)+(W+0.68)+(H+0.34) and the result of substituting the value is 1401.5MM

[0060] Logo 2 size is 332.7MM

[0061] The plate thickness is 2MM, and the edge fillet on the bending machine is R=0.8~1MM

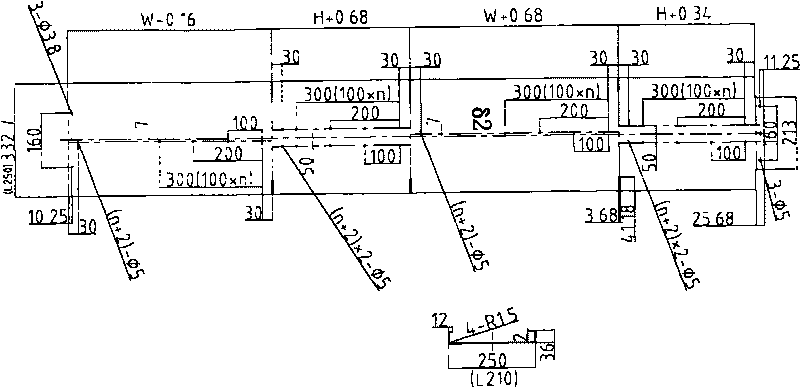

[0062] 2. Stamping (see attached image 3 )

[0063]Use customized stamping dies to perform corner cutting, blanking, punching and other processes on the sheet metal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com