Dosing and/or transport of powdery and/or pourable solids

A solid material, powdery technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve problems such as pneumatic transmission blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

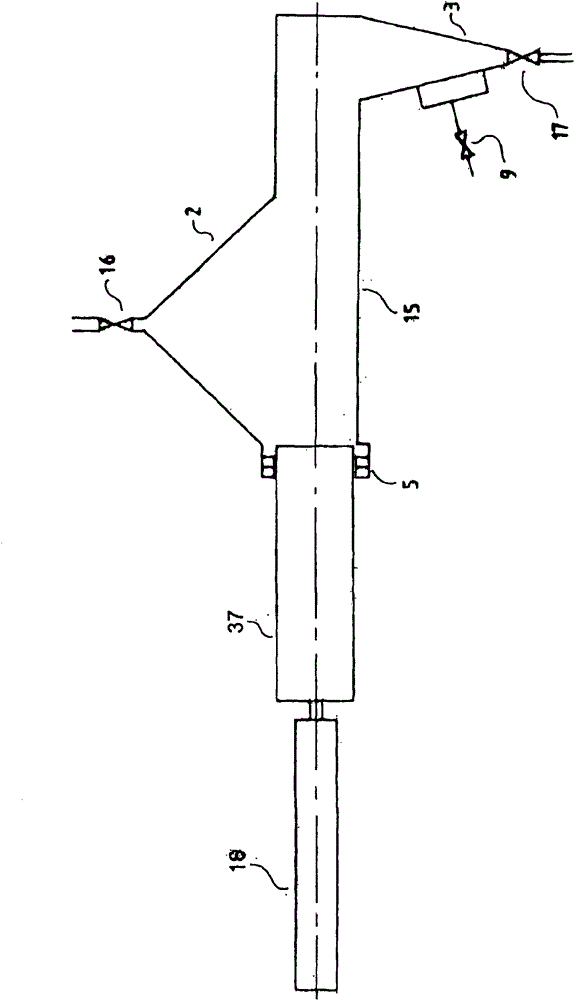

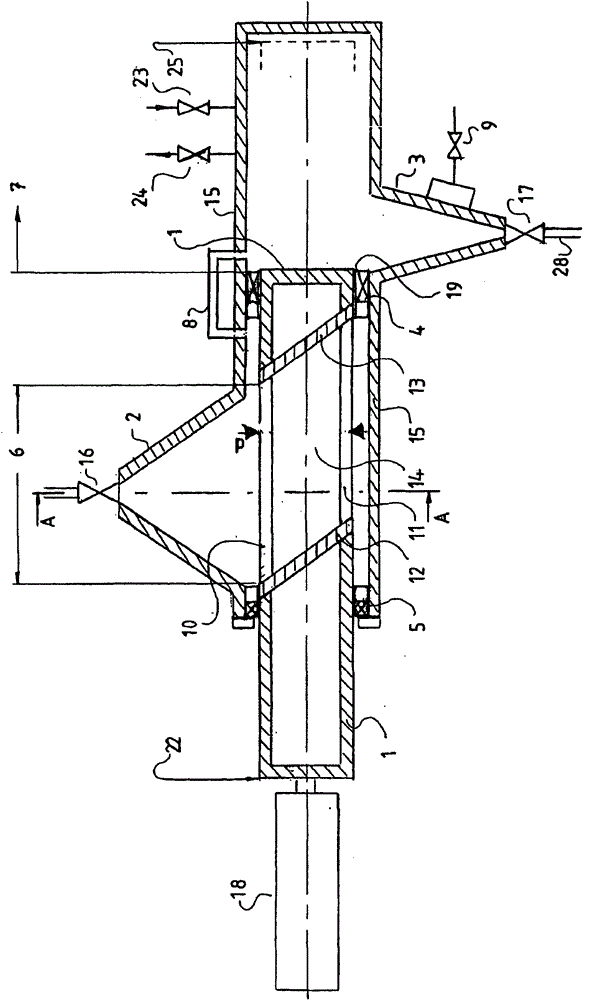

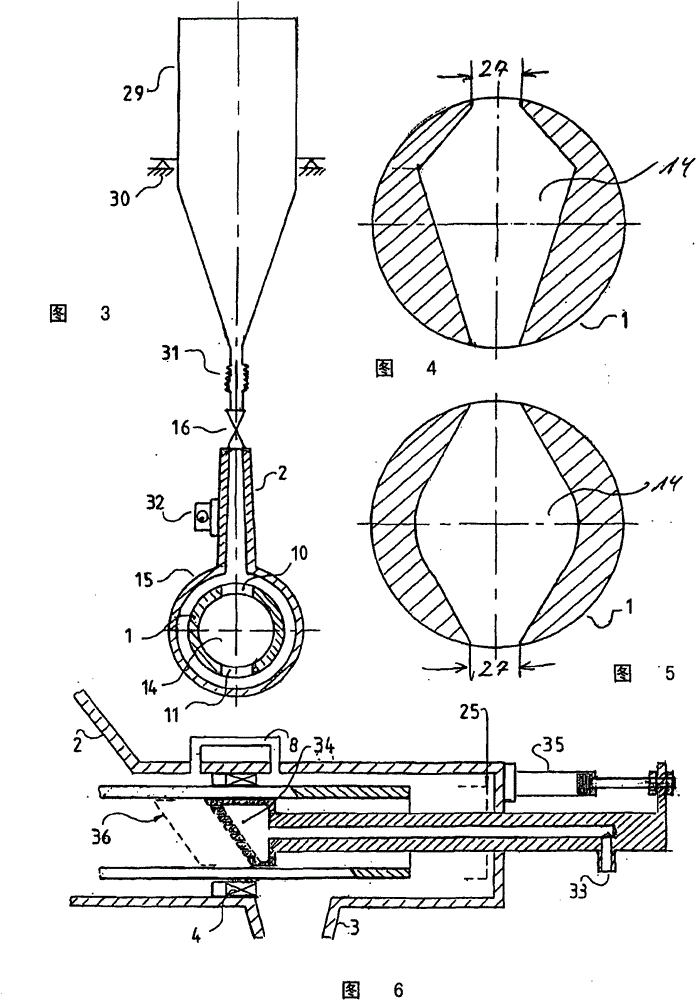

[0044] figure 1 A device known from the prior art (DE 195 38 622 C1) is shown. The device basically consists of a housing 15 with a funnel-shaped inlet 2 and a conical outlet 3 and a piston 19 with a sealed bearing 5 . By opening the inlet valve 16, material flows into the housing 15 and fills it completely. After closing the inlet valve 16 , the outlet valve 17 and delivery gas valve 9 are opened, and the linear drive mechanism 18 pushes the cylindrical piston 37 into the housing 15 . The material located in front of the cylindrical piston 37 in the housing is compacted and begins to fall into the cone after a corresponding push stroke according to the compressibility of the horizontal material column and the friction of the material on the inner wall of the housing. Exporting. Soft materials or materials with a high percentage of fines can compress to the point of agglomeration, which can block the outlet and also jam the linear drive mechanism due to excessive resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com