Bulletproof composite board

A composite board and disc technology, applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of low hardness, inability to effectively block high-speed bullets, and poor destructive ability of bullets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

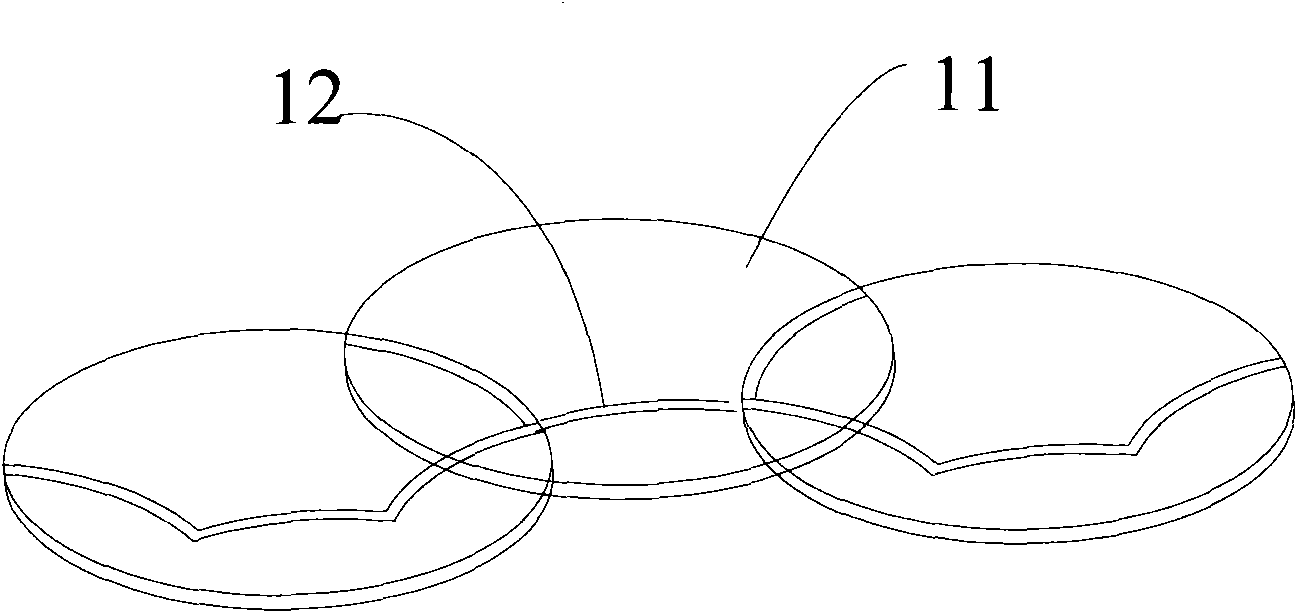

[0042] see Figure 4 . When preparing the absorbent layer, 4 sheets of non-woven fabrics are stacked, the fibers in adjacent non-woven fabrics are arranged at 45 degrees, and the stacked non-woven fabrics are subjected to a pressure of 1.5 MPa at 95°C to obtain a non-woven fabric laminate 21a. Take 4 non-weft fabric laminates 21a and 3 knitted fabrics 21b for stacking (only partially superimposed non-weft fabric laminates and knitted fabrics are shown in the figure), when superimposing, place a knitted fabric in the middle of each two non-weft fabric laminates. The stacked non-woven fabric and knitted fabric were heated to 115° C. and a pressure of 2.5 MPa was applied to pre-press the molded part. The pre-pressed molded parts were placed in a vacuum oven with a temperature of 128° C. for 20 minutes, and the vacuum degree in the vacuum oven was 0.18 kpa. After vacuum heat preservation treatment, cool to room temperature, take out the pre-pressed molding, put it in a hot-press...

Embodiment 2

[0046] When preparing the absorbent layer, take 4 pieces of non-weft fabrics and stack them, the fibers in the adjacent non-weft fabrics are arranged at 90 degrees, and apply a pressure of 1.5 MPa to the superimposed non-weft fabrics at 95°C to obtain a non-weft fabric laminate. Take 4 non-weft laminations and 3 knitted fabrics and stack them. When superimposing, place a knitted fabric in the middle of each two non-wefted laminations. The stacked non-woven fabric and knitted fabric were heated to 115° C. and a pressure of 2.5 MPa was applied to pre-press the molded part. The pre-pressed molded parts were placed in a vacuum oven with a temperature of 128° C. for 20 minutes, and the vacuum degree in the vacuum oven was 0.18 kpa. After vacuum heat preservation treatment, cool to room temperature, take out the pre-pressed molding, put it in a hot pressing mold, heat up to 127°C, apply a pressure of 16MPa for 30min, and cool to room temperature to obtain an absorption layer.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com