Submersed type inspection well construction method

A construction method and inspection well technology, applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve problems such as increasing the cost of pipe jacking projects, hindering the development of pipe jacking construction technology, increasing the number of working wells or receiving wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

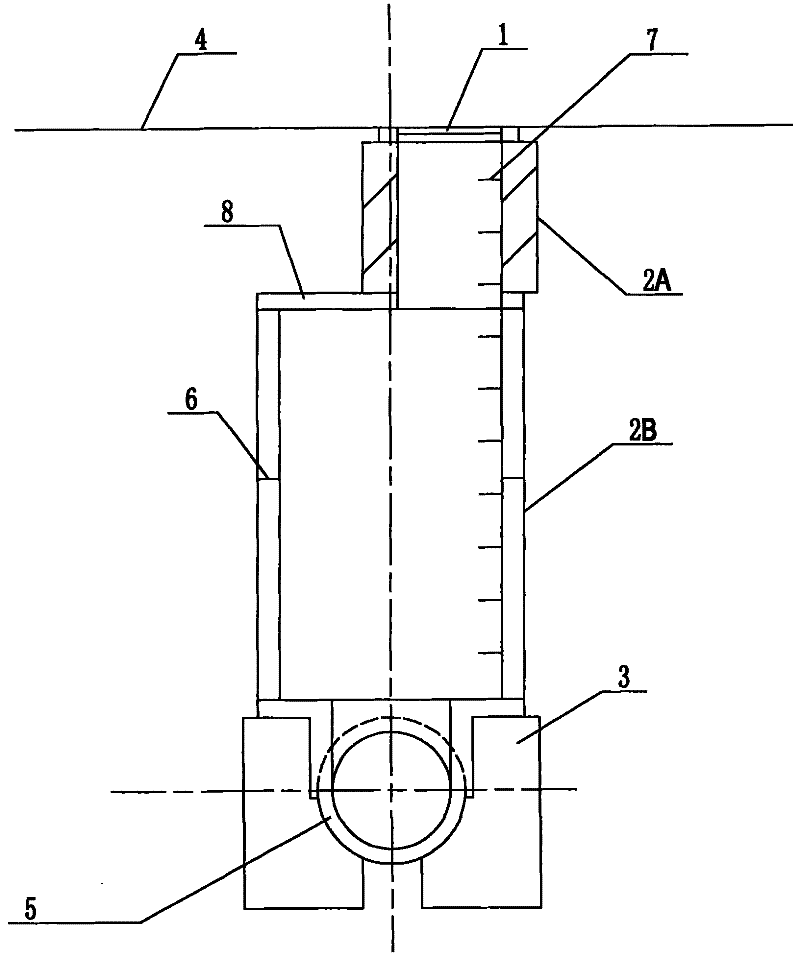

[0024] Such as figure 1 As shown, the immersed tube inspection well applicable to the present invention includes a well cover 1 on the ground and a well shaft 2 below the well cover 1. Below the well shaft 2 is an existing drainage pipe 5, and a foundation is poured between the lower end of the well shaft 2 and the drainage pipe 5. 3. The lower end of the wellbore 2 and the upper end of the foundation 3 are poured into one body, the diameter of the foundation 3 ≥ the outer diameter of the wellbore + 0.1 meters, the bottom of the foundation 3 is located 0.3 meters below the skin of the existing drainage pipe 5, and the bottom of the foundation 3 extends inwards to the existing 1 / 3 of the diameter of the drainage pipe 5. Among them, the wellbore 2 consists of upper and lower parts. The upper shaft 2A extends downward from the road surface to the subgrade elevation (usually 2.5 meters below the road surface) and its cross section is smaller than that of the lower shaft. The lower...

Embodiment 2

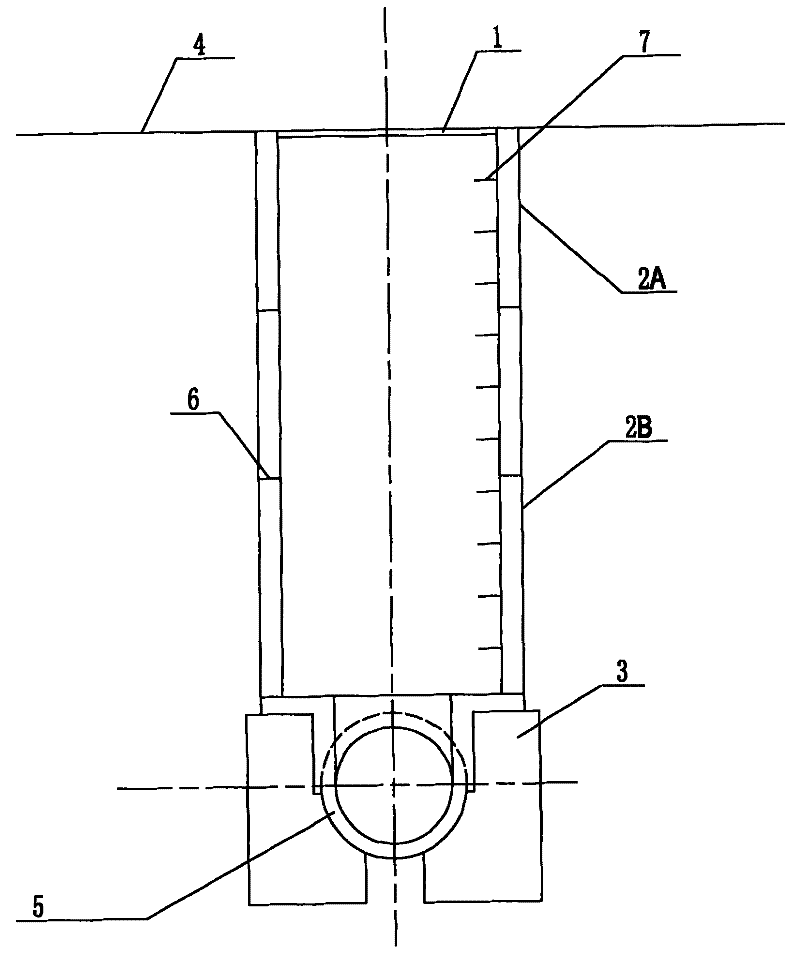

[0041] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that the wellbore is not divided into the upper section wellbore and the lower section wellbore (adopting "F" type reinforced concrete pipe), so there is no need to set the wellbore cover plate 8; the stage (4 ); Step 4 of stage (2) should repeat the process of connecting the wellbore at last to connect the wellbore to the road surface.

[0042] The wellbore 2 in this embodiment is not divided into the upper section and the lower section, and should be adopted when there are no other pipelines under the road surface at the construction site, which can simplify the construction process.

[0043] By adopting the structure and construction method of the present invention, it is convenient to adopt the immersed tube construction method to manufacture inspection wells, thereby facilitating long-distance pipe jacking construction, developing new prefabricated inspection well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com