Method for straightening tank plate containing nickel and vanadium

A steel plate and straightening technology, which is applied in the field of flattening of hot-rolled container steel plates, can solve the problem of unseen document records and data reports on the straightening of hot-rolled container steel plates, the inability to guarantee the delivery time of steel plates, and the deformation of steel plates It can reduce the flatness rectification rate, improve the overall yield, and determine the scientific parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

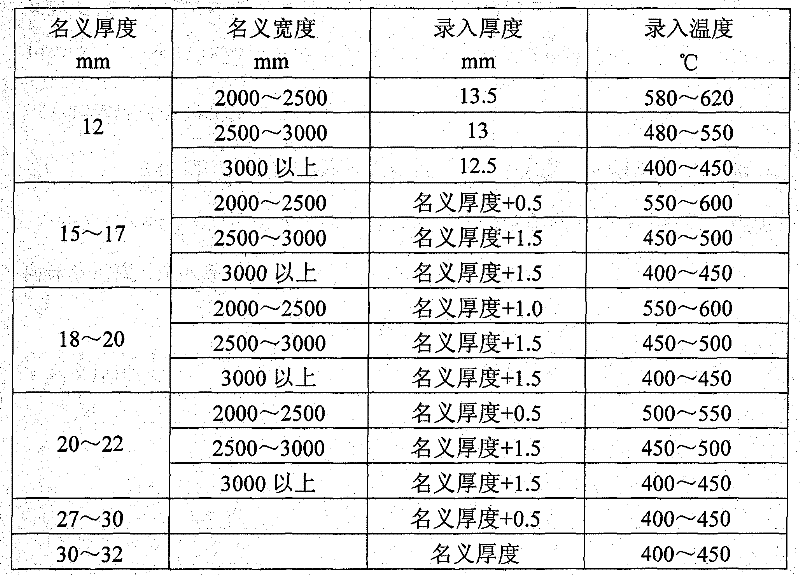

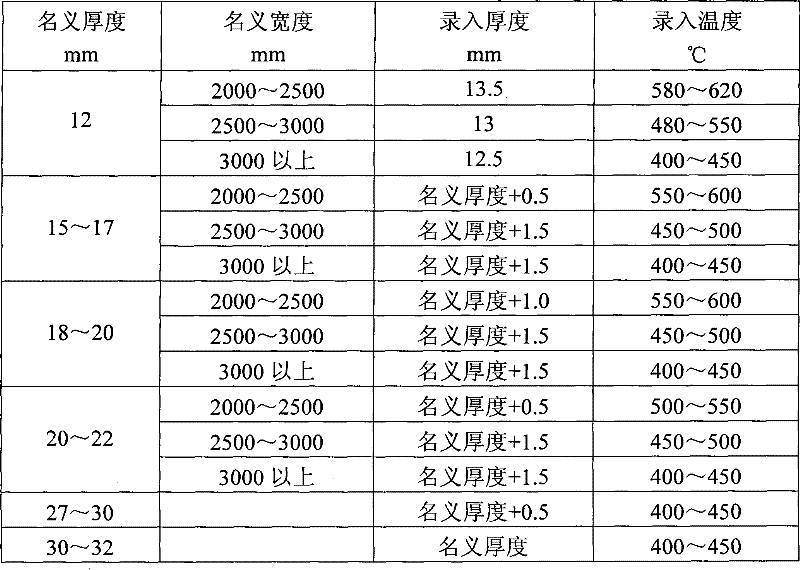

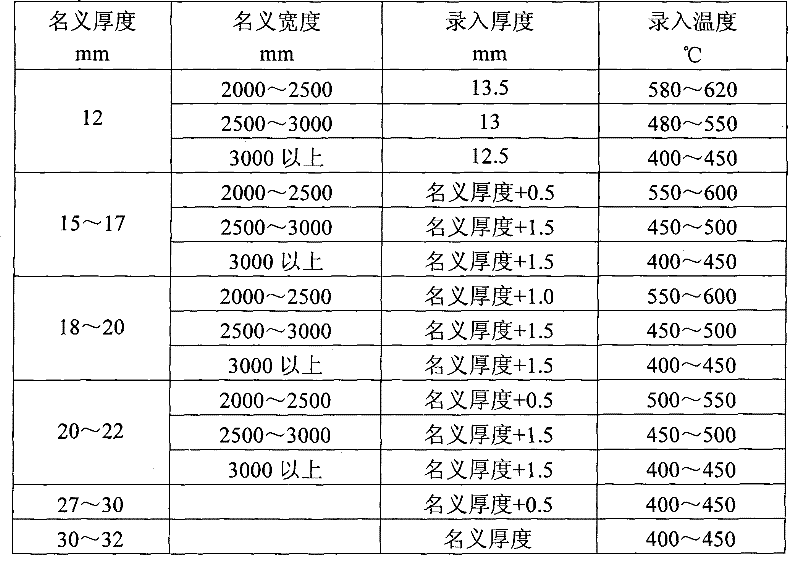

Embodiment 1

[0027] 08MnNiVR hot-rolled container steel plate, after rolling, the plate shape has a central wave shape, nominal thickness: 12mm, nominal width: 3000mm. Select the corresponding input thickness as 13mm and input temperature as 550°C, input the input thickness and input temperature into the straightening model set by the computer, and adjust the straightening force through the computer straightening model to control the shape of the plate. At the same time, manually enter the roll bending mode, and use -2.2 negative roll bending to straighten three times.

Embodiment 2

[0029] 16MnNiVR hot-rolled container steel plate, after rolling, the plate shape appears wavy, nominal thickness: 21mm, nominal width: 3200mm. Select the corresponding input thickness as 22.5mm and input temperature as 400°C, input the input thickness and input temperature into the straightening model set by the computer, and adjust the straightening force through the computer straightening model. At the same time, manually enter the bending mode, and use +1.4 positive bending rolls to straighten three times.

Embodiment 3

[0031] 08MnNiVR hot-rolled container steel plate, after the steel plate is rolled, the shape of the steel plate has a head curvature, the nominal thickness of the steel plate: 32mm, and the nominal width: 2800mm. Select the corresponding input thickness as 32mm and input temperature as 400°C, input the input thickness and input temperature into the straightening model set by the computer, and adjust the straightening force through the computer straightening model. The bending roll is not adjusted, and the hot-rolled container plate containing nickel and vanadium components can be produced with qualified plate shape after three straightening passes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com