Plasma processing equipment, its radio frequency apparatus and radio frequency conveying method

A technology of radio frequency devices and processing equipment, applied in the field of microelectronics, can solve problems such as uneven plasma, uneven electromagnetic field, and differences in processing speed of plasma density workpieces, and achieve the effect of improving uniformity and eliminating differences in concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

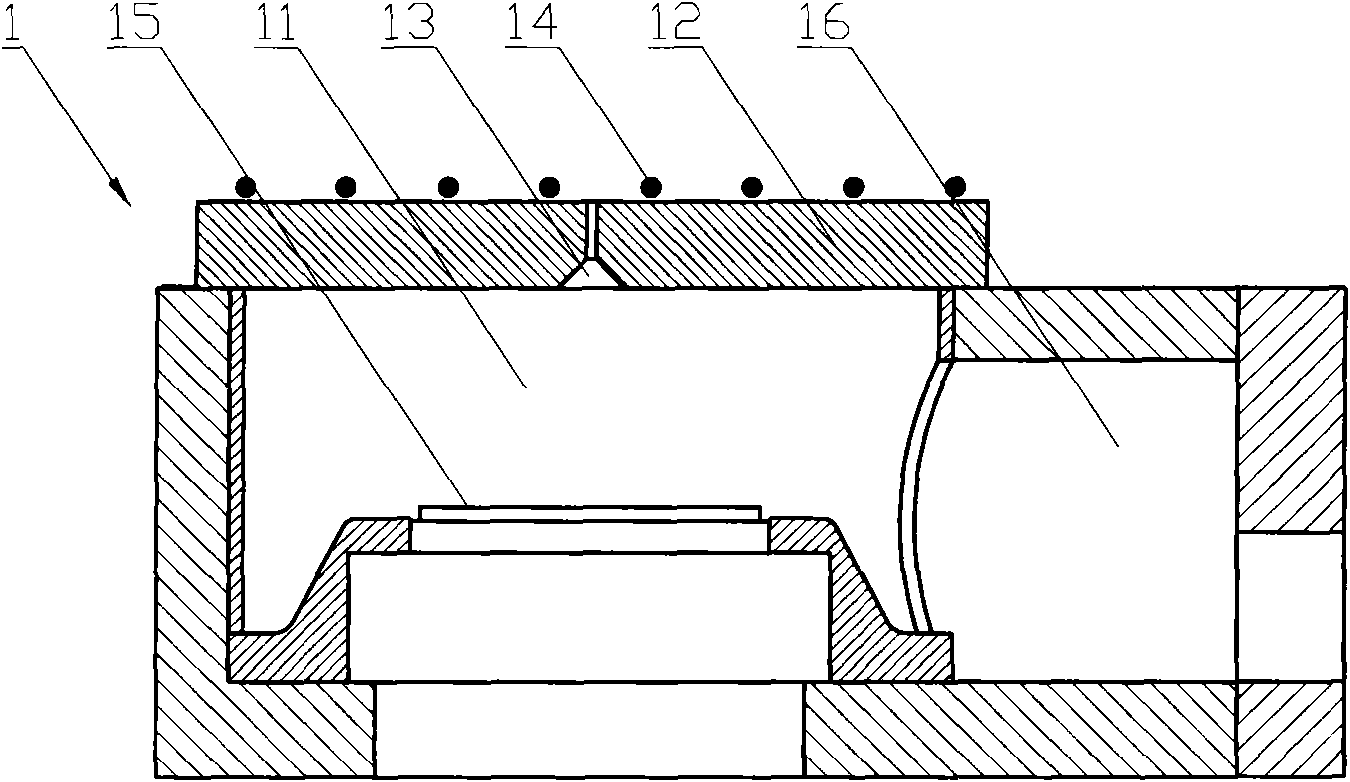

[0032] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

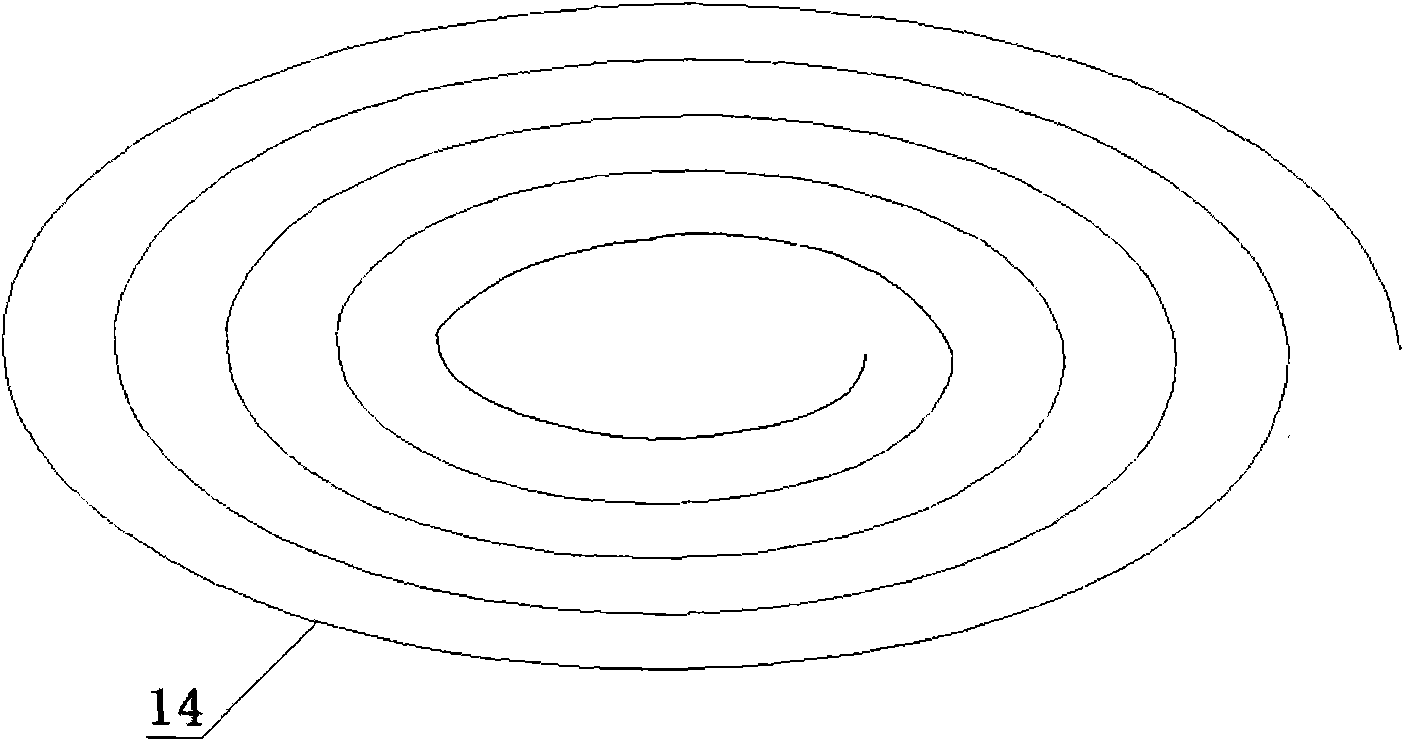

[0033] The radio frequency device for plasma processing equipment provided by the present invention includes a radio frequency power supply, a radio frequency matching device and an inductive coupling coil, and the three are connected in sequence.

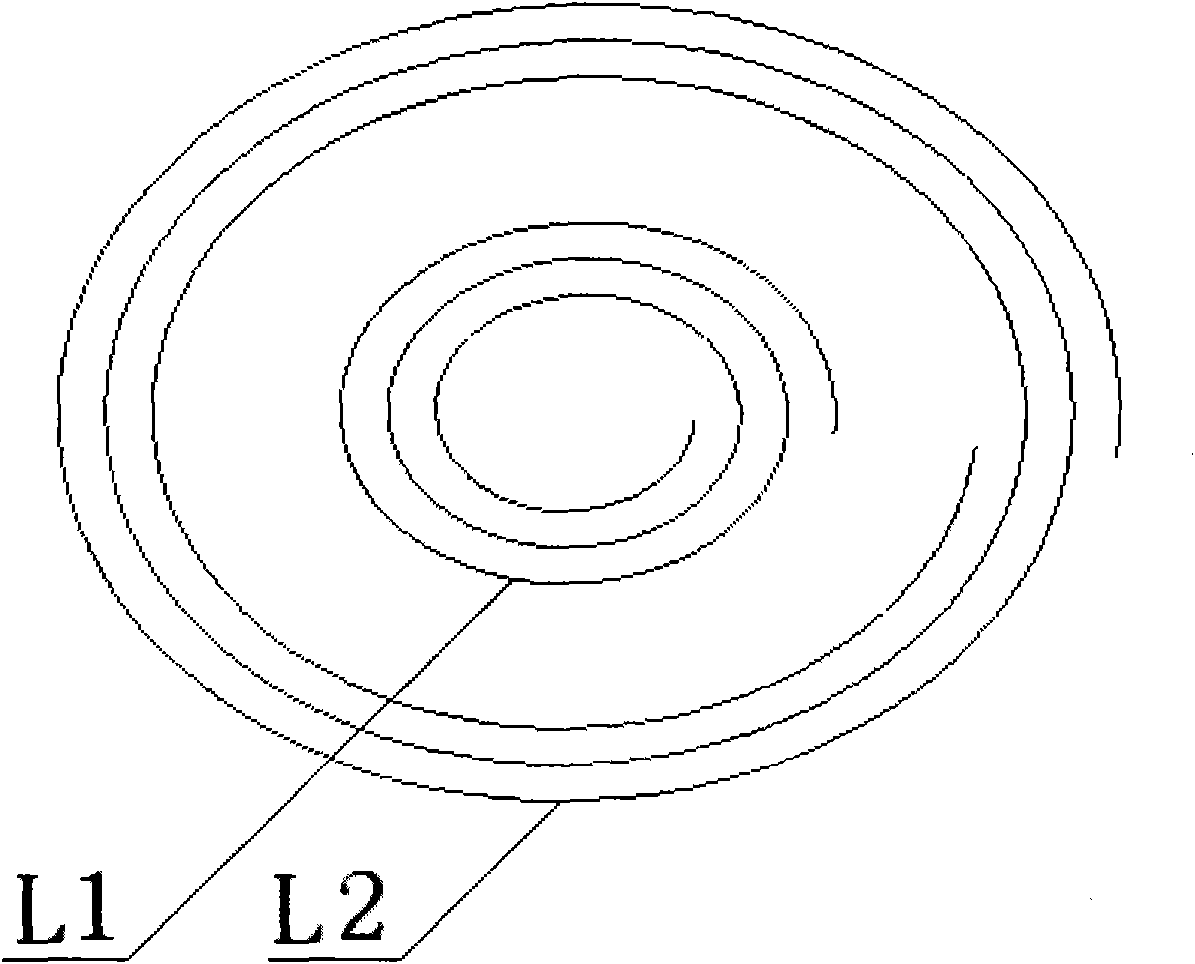

[0034] Please refer to image 3 , image 3 It is a structural schematic diagram of a specific embodiment of the inductively coupled coil provided by the present invention.

[0035] In the first specific implementation manner, the inductively coupled coil provided by the present invention includes at least two independent parts, that is, the central coil L1 and the peripheral coil L2.

[0036] The central coil L1 is located at the center of the top of the reaction chamber of the plasma ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com