Equalizing plate structure

A technology of vapor chamber and metal plate, applied in lighting and heating equipment, indirect heat exchanger, cooling/ventilation/heating transformation, etc., can solve problems such as welding defects, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

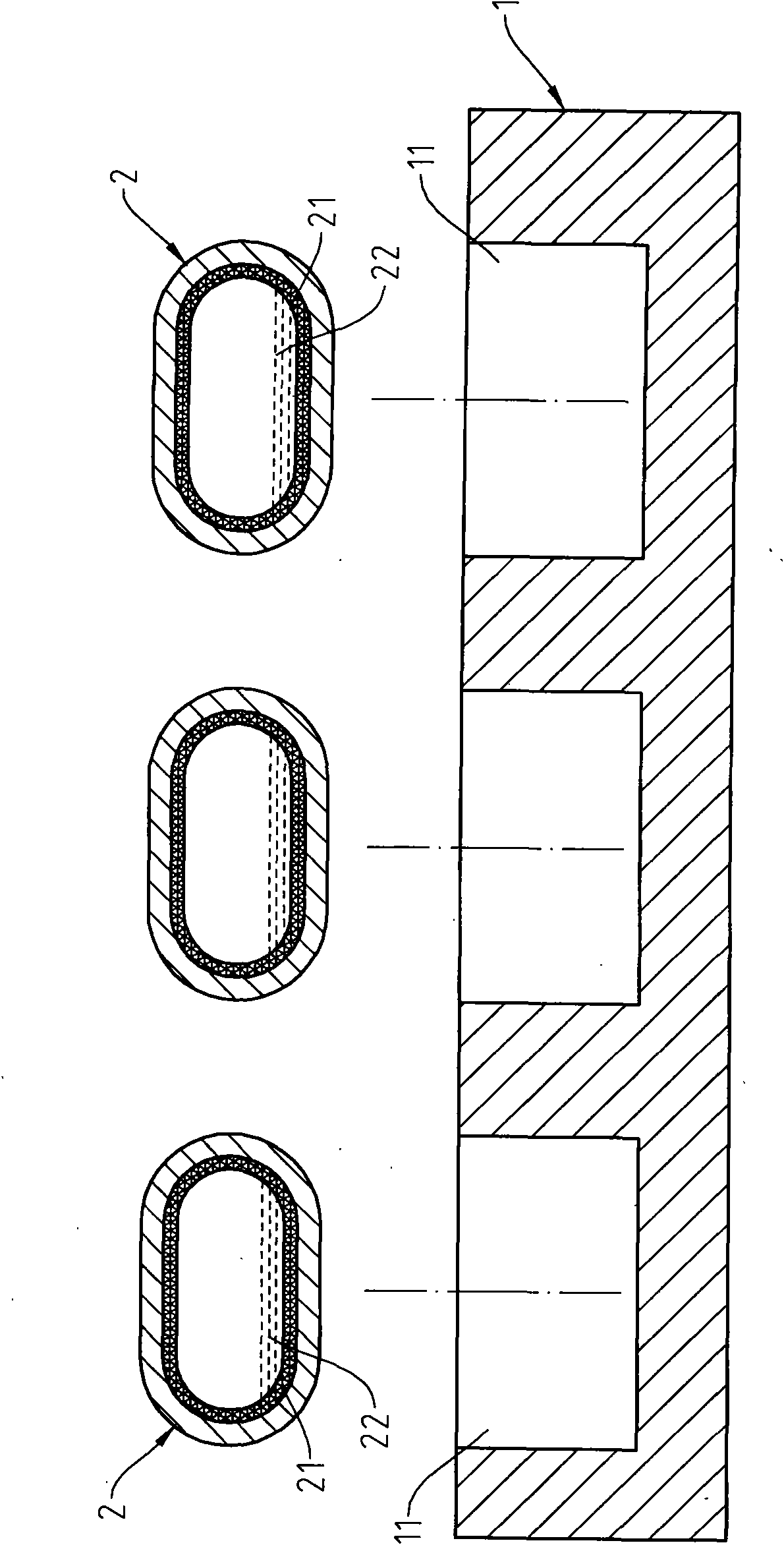

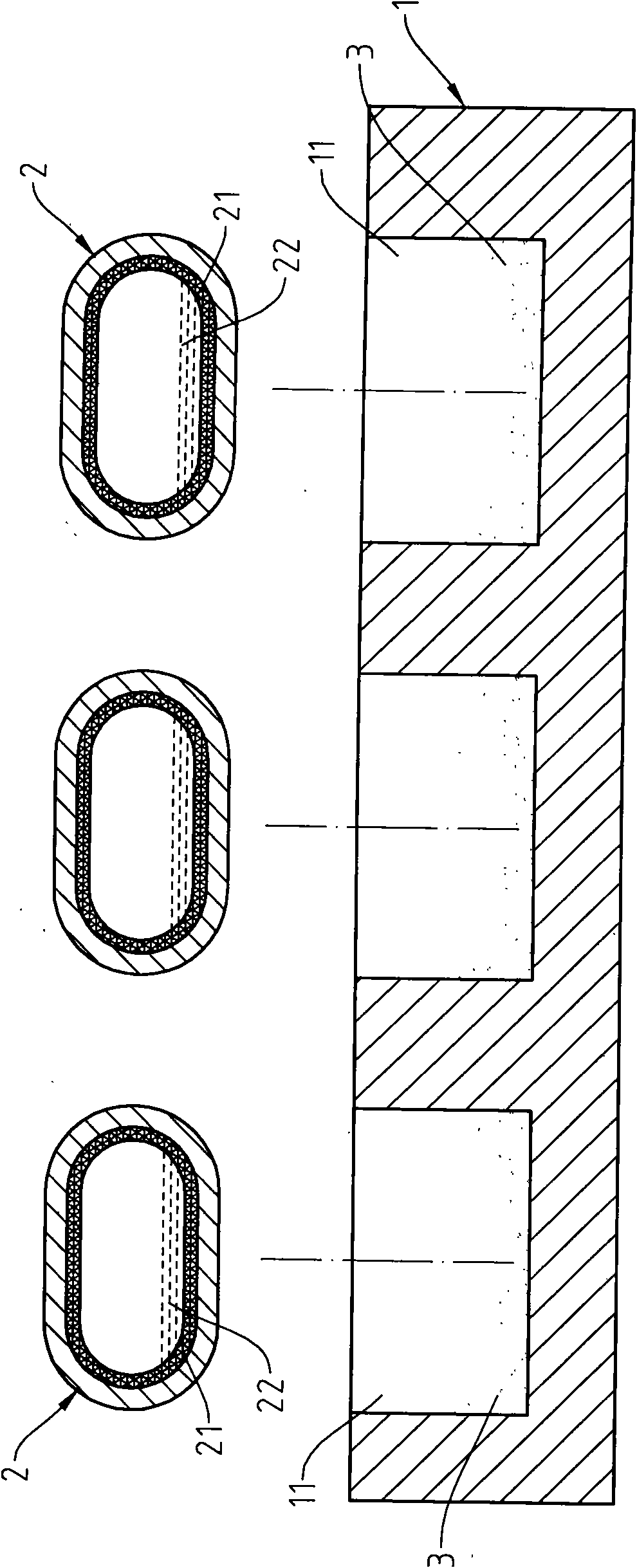

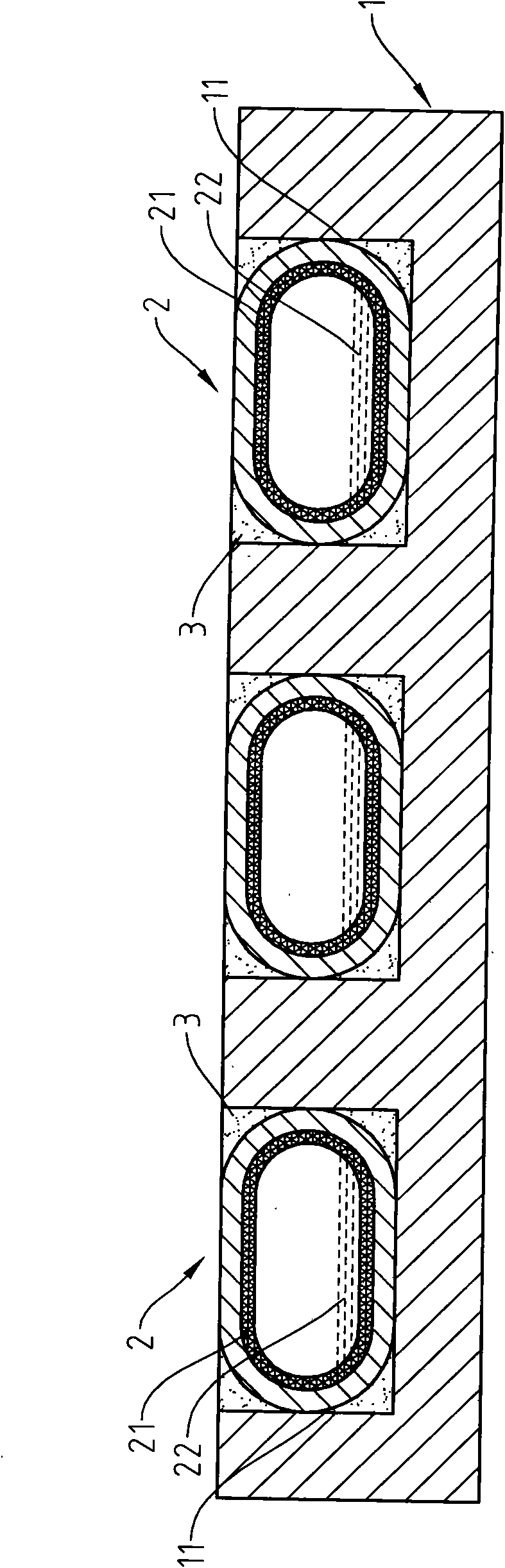

[0018] see Figure 1 to Figure 4 As shown, it can be clearly seen from the figure that the present invention is provided with a metal plate 1 and a heat pipe 2, wherein:

[0019] A plurality of accommodating spaces 11 are recessed on the surface of the metal plate 1 .

[0020] The inner wall of the heat pipe 2 is sintered with a capillary structure 21 , and an appropriate amount of working fluid 22 is stored in the heat pipe 2 .

[0021] When the vapor chamber of the present invention is manufactured, an appropriate amount of solder 3 is first coated in the accommodation space 11, and the heat pipes 2 are prefabricated into a geometric shape close to the accommodation space 11, and then each heat pipe 2 is inserted into the metal In the accommodating space 11 of the plate 1, at this time, the solder 3 will fill in the gap formed by the heat pipe 2 and the accommodating space 11, and then the metal plate 1 is sent to the reflow furnace for heating, so that the heat pipe 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com