Gravity pressure water delivery system with automatic-adjusting weir well

A water delivery system and automatic adjustment technology, applied in water conservancy projects, water supply installations, water supply installations, etc., can solve the problems of maintenance, maintenance and update being controlled by people, high management costs, and increased pressure on the downstream pipelines of water delivery pipes. It is beneficial to hydraulic inertia control, simple hydraulic control, and the effect of reducing the buried depth of pipes and culverts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

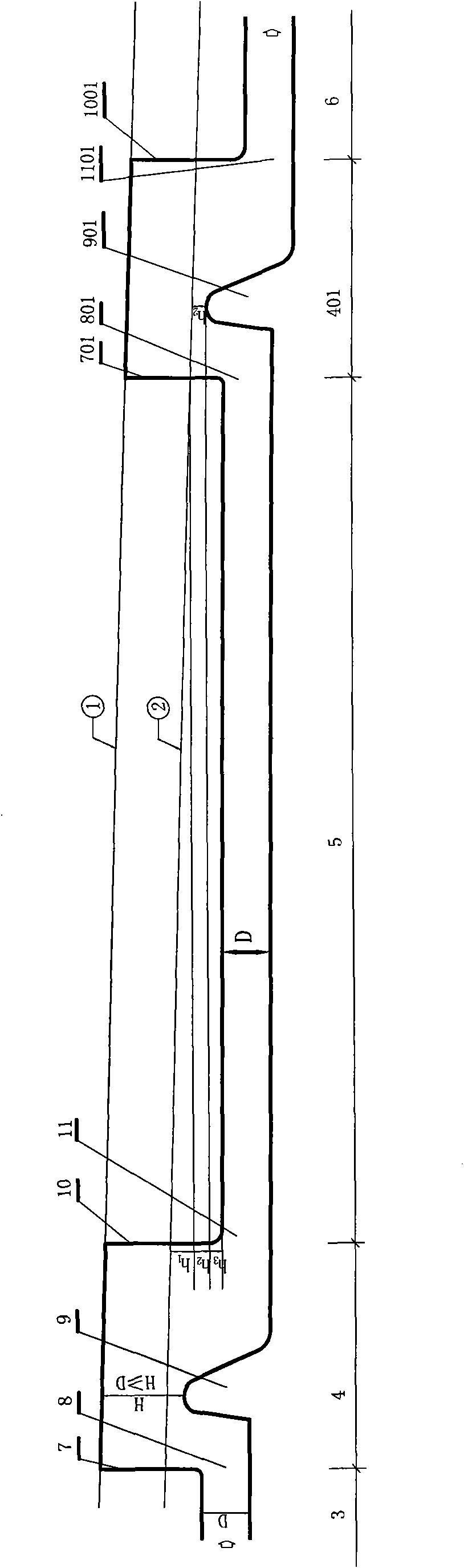

[0028] This embodiment is a kind of gravity pressurized water delivery system with automatic adjustment weir well, such as figure 1 shown. The system described in this embodiment includes: an upstream water delivery inlet 3 arranged on the water supply side and a downstream water delivery outlet 6 arranged on the water supply side, and at least one water delivery outlet is connected through a pipeline 5 between the water delivery inlet and the water delivery outlet. Adjust weir well 4,401. The regulating weir well includes: the weir well water inlets 8 and 801 at the bottom of the inlet parapets 7 and 701 of the regulating weir well connected to the upstream pipeline, the two sides of the inlet parapet are respectively connected to the weir well side walls, and the weir well side walls are connected to the regulating weir well side walls. The outlet parapet 10, 1001 of the weir well, the bottom of which is the weir well water outlet 11, 1101 connected with the downstream wate...

Embodiment 2

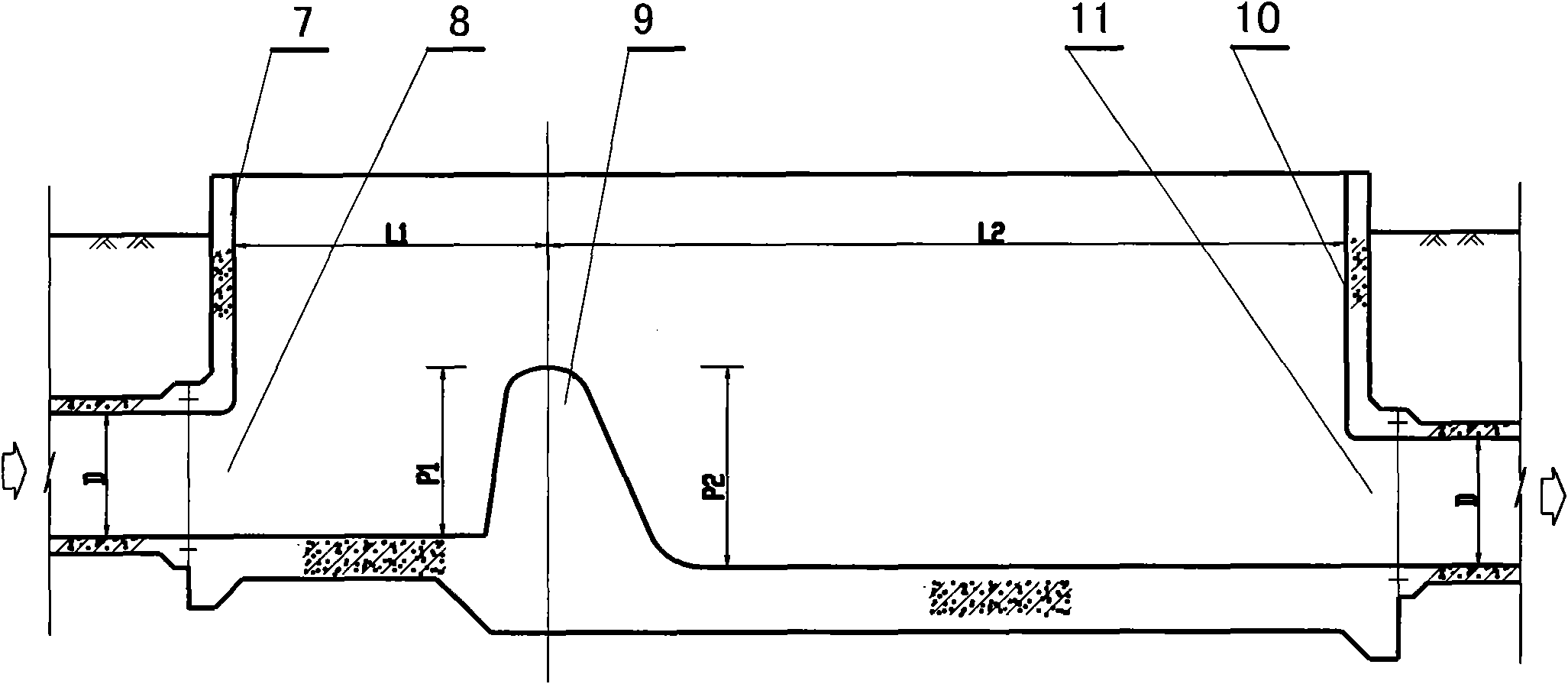

[0034] This embodiment is an improvement of Embodiment 1, which is the refinement of the overflow weir in Embodiment 1, such as figure 2 shown. The overflow weir of the regulating weir well described in this embodiment is a rounded broken-line practical weir type, and the distance from the inlet parapet to the center of the overflow weir (or "upstream distance of the overflow weir", or more simply "upstream of the weir") ) is not less than the height of the water inlet of the weir well, and the height of the overflow weir is: at the minimum operating flow rate, the submerged depth of the water inlet of the weir well is not less than 1.0 meters, the submerged depth of the weir well outlet is not less than 1.5 meters, and the weir top to the regulating The height of the wellhead of the weir well is greater than or equal to the height of the water inlet of the weir well, and the distance between the center of the overflow weir and the outlet parapet (or "distance downstream of t...

Embodiment 3

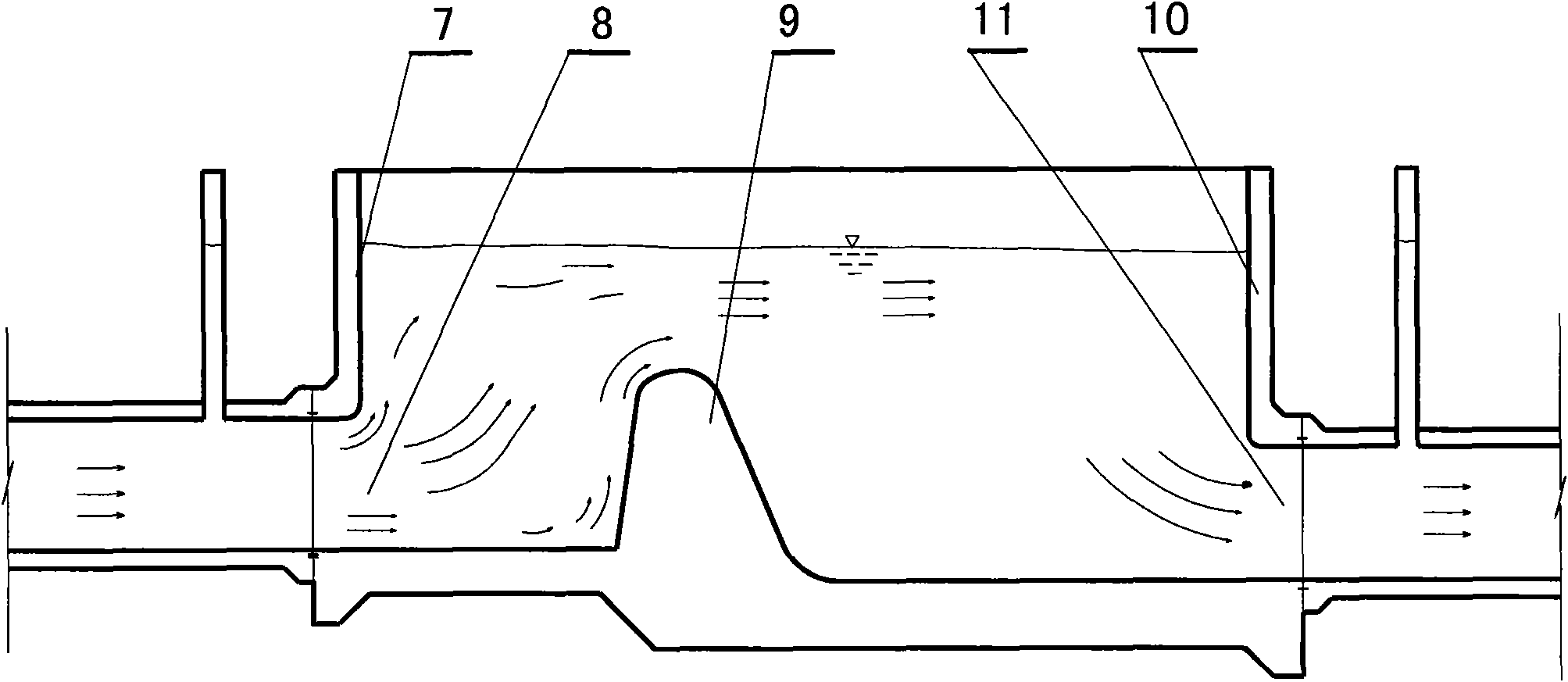

[0096] This embodiment is an improvement of Embodiment 2 and a refinement of Embodiment 2, such as Figure 5 shown. A stilling pool 13 is set between the overflow weir of the regulating weir well and the outlet breast wall in this embodiment, and 3 to 4 vortex-eliminating beams 12 are arranged horizontally and arc-shaped above the stilling pool, and the vortex-eliminating beams It is a rod-shaped cylinder, the cross arm is between the two side walls, and the height is higher than the overflow weir crest.

[0097] In order to increase the depth of the water cushion downstream of the overflow weir and improve the energy dissipation rate, the floor elevation of the downstream side of the weir well is 1.5m lower than that of the bottom plate of the downstream box culvert entrance to form a stilling pool, which is connected to the bottom plate of the downstream box culvert with a slope of 1:1. connect. In order to prevent the vortex of the through-type funnel, a vortex-eliminatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com