Manufacturing method of sheath-core fibrilia

A production method and technology of hemp fiber, which are applied in fiber processing, cellulose/protein conjugated rayon filament, and conjugated synthetic polymer rayon filament, etc., can solve the problem of low public count, rough hemp fiber, poor elasticity, etc. problem, to achieve the effect of simple production method and good touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

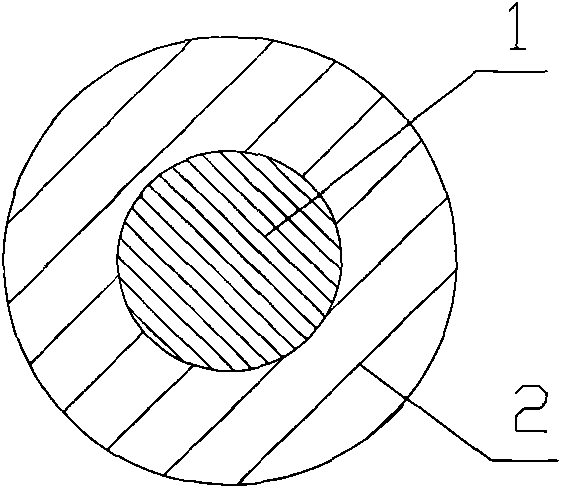

[0019] Such as figure 1 Shown, the sheath-core hemp fiber of present embodiment is made of the jute fiber 1 as core layer and the cortex polylactic acid 2 of wrapping jute fiber 1, and described jute fiber 1 passes through silane coupling agent (chemical name is vinyl triethoxylate) base silane, the chemical structural formula is CH2CHSi (OC2H5) 3) processed, and the molecular formula of the polylactic acid is: Its average molecular weight is 120,000 Daltons, and the weight ratio of the polylactic acid 2 to the hemp fiber 1 is 3:7.

[0020] The production method of above-mentioned sheath-core hemp fiber comprises the steps:

[0021] A: Select polylactic acid slices and hemp fibers with a suitable weight ratio, heat the polylactic acid slices at 100°C for 8 hours, vacuum dry them, and send them to the spinning storage barrel after cooling; soak the jute fibers with a silane coupling agent, and then to dry;

[0022] B: The dried polylactic acid chips and jute fibers are comp...

Embodiment 2

[0026] Different from the foregoing embodiments, the weight ratio of polylactic acid and jute fibers in this embodiment is 4:6.

[0027] Example 2:

[0028] Different from the foregoing embodiments, the weight ratio of polylactic acid and jute fibers in this embodiment is 5:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com