Citric acid alidenafil crystal form D and preparation method and usage thereof

A technology of citric acid and amorphous form, which is applied in the field of edenafil citrate crystal form D and its preparation and application, and can solve problems not related to edenafil citrate crystal form and its preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

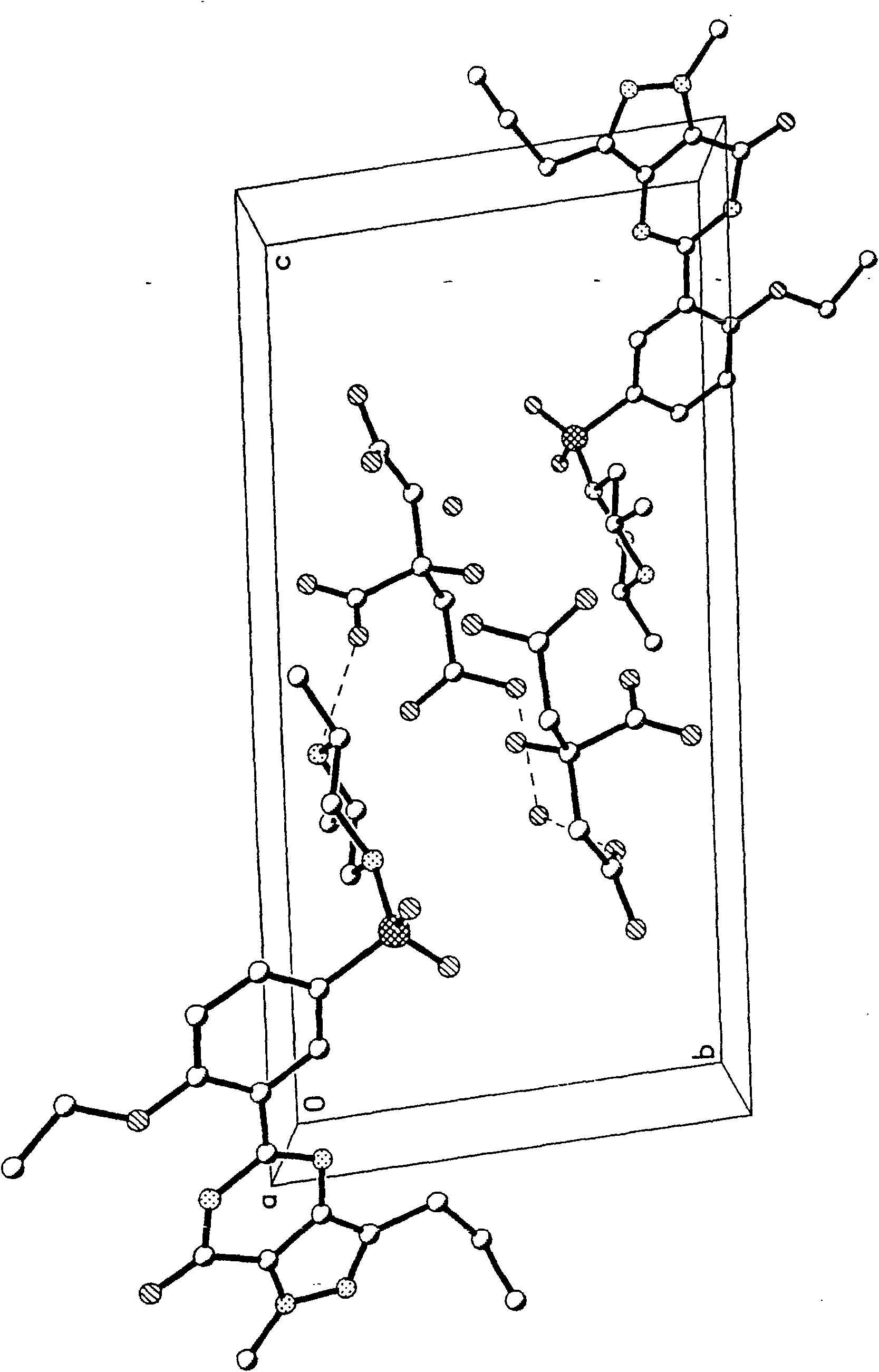

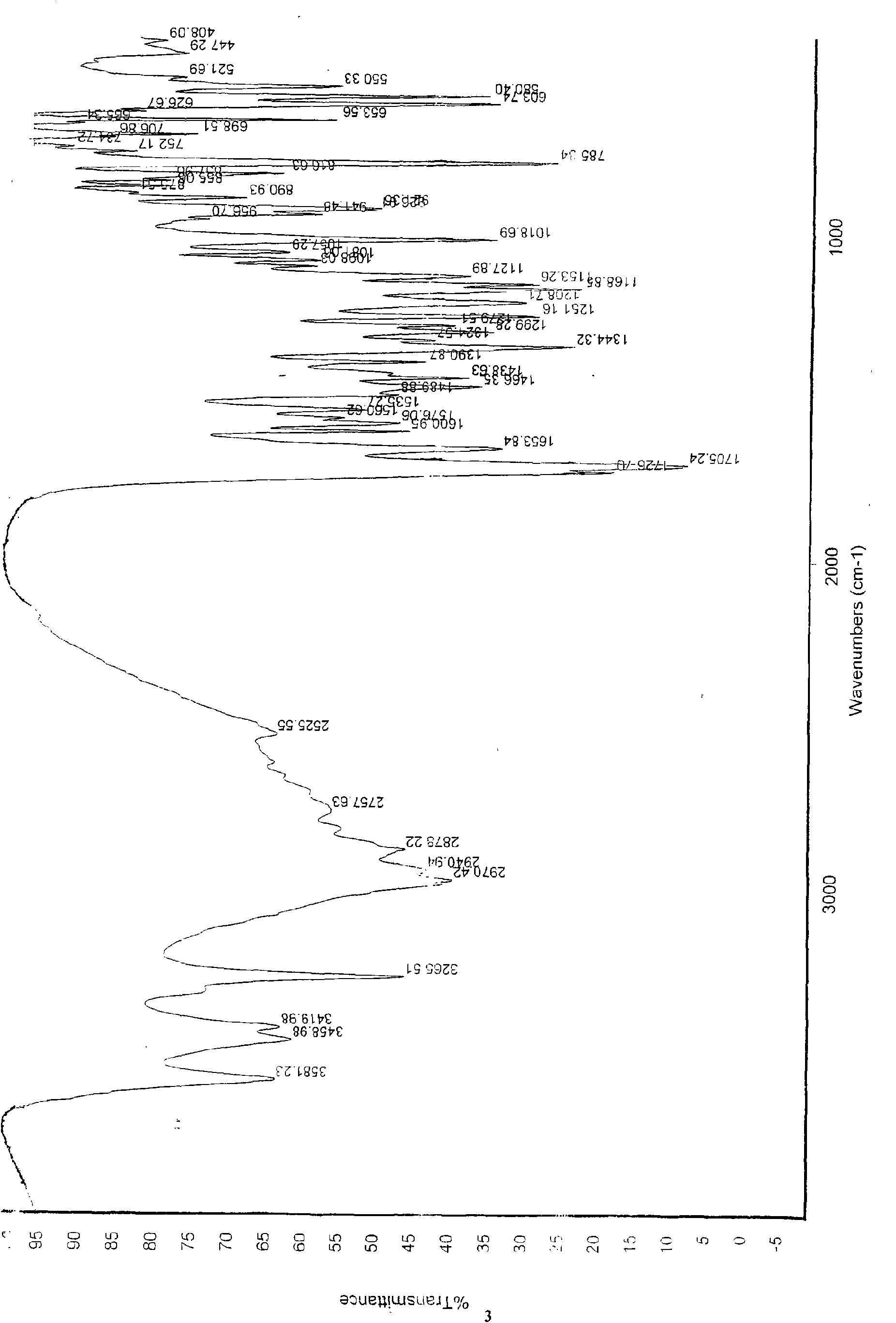

[0094] In a 100ml reaction bottle, add 3 grams of edenafil citrate, 85ml of distilled water / absolute ethanol (50:50, volume ratio), start stirring, heat up to reflux temperature, filter while hot after 15 minutes, and seal the container Put the filtrate in a filter bottle, place it indoors, lower the temperature naturally to 30°C-35°C, keep it warm for 58 hours, precipitate crystals, filter, place it indoors for 1 hour, and dry to obtain the crystalline form of aldenafil citrate D 1.8g, its melting point is m.p 201.9-203.1°C, the refining rate is 60%, and the content measured by HPLC area normalization method is 99.92%. See figure 1 , figure 2 , image 3 and Image 6 , is the three-dimensional structure projection diagram, unit cell projection diagram, infrared spectrum diagram and X-ray powder diffraction diagram of aldenafil crystal form D citrate molecule, showing the characteristics of aldenafil crystal form D citrate.

Embodiment 2

[0096] In a 200ml reaction bottle, add 5 grams of edenafil citrate, 160ml of distilled water / absolute ethanol (40:60, volume ratio), start stirring, heat up to reflux temperature, filter while it is hot after 15 minutes, and seal it. Put the filter bottle of the filtrate, place it indoors, cool down naturally to 30°C-35°C, keep it warm for 65 hours, precipitate crystals, filter, place it indoors for 1 hour, and dry to obtain Aldenamorph citrate crystal form D 2.8g, its melting point is m.p 201.9-203.1°C, the refining rate is 56%, and the content measured by HPLC area normalization method is 99.92%. After testing, it showed the characteristics of edenamorph citrate crystal form D.

Embodiment 3

[0098] Granules Containing Aldenafil Citrate Form D

[0099] Prescription: 50 grams of Aldenafil Citrate Form D, 650 grams of lactose, 100 grams of crospovidone, 90 grams of PEG-4000, 135 grams of hydroxypropyl methylcellulose, appropriate amount of distilled water, made into 1000 bags.

[0100] Process: PEG-4000 and aldenamorph citrate crystal form D are crushed together, passed through an 80-mesh sieve, mixed with other materials, made into soft materials with distilled water, granulated, dried at low temperature, and then packaged into granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com