Heat dissipation module, temperature equalizing element and manufacturing method for temperature equalizing element

A manufacturing method and component technology, applied in cooling/ventilation/heating transformation, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of affecting heat conduction efficiency, high level of mold and fixture technology, capillary force decline, etc., to achieve Simplify the manufacturing process steps, easily change the geometric shape, and increase the effect of heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

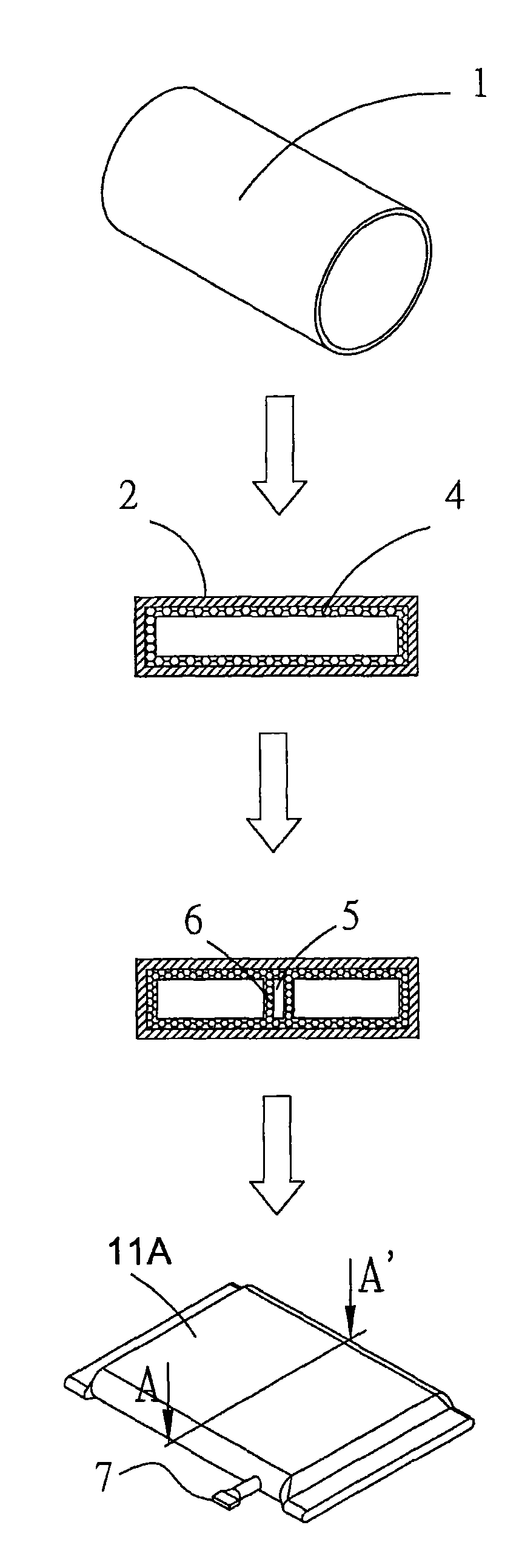

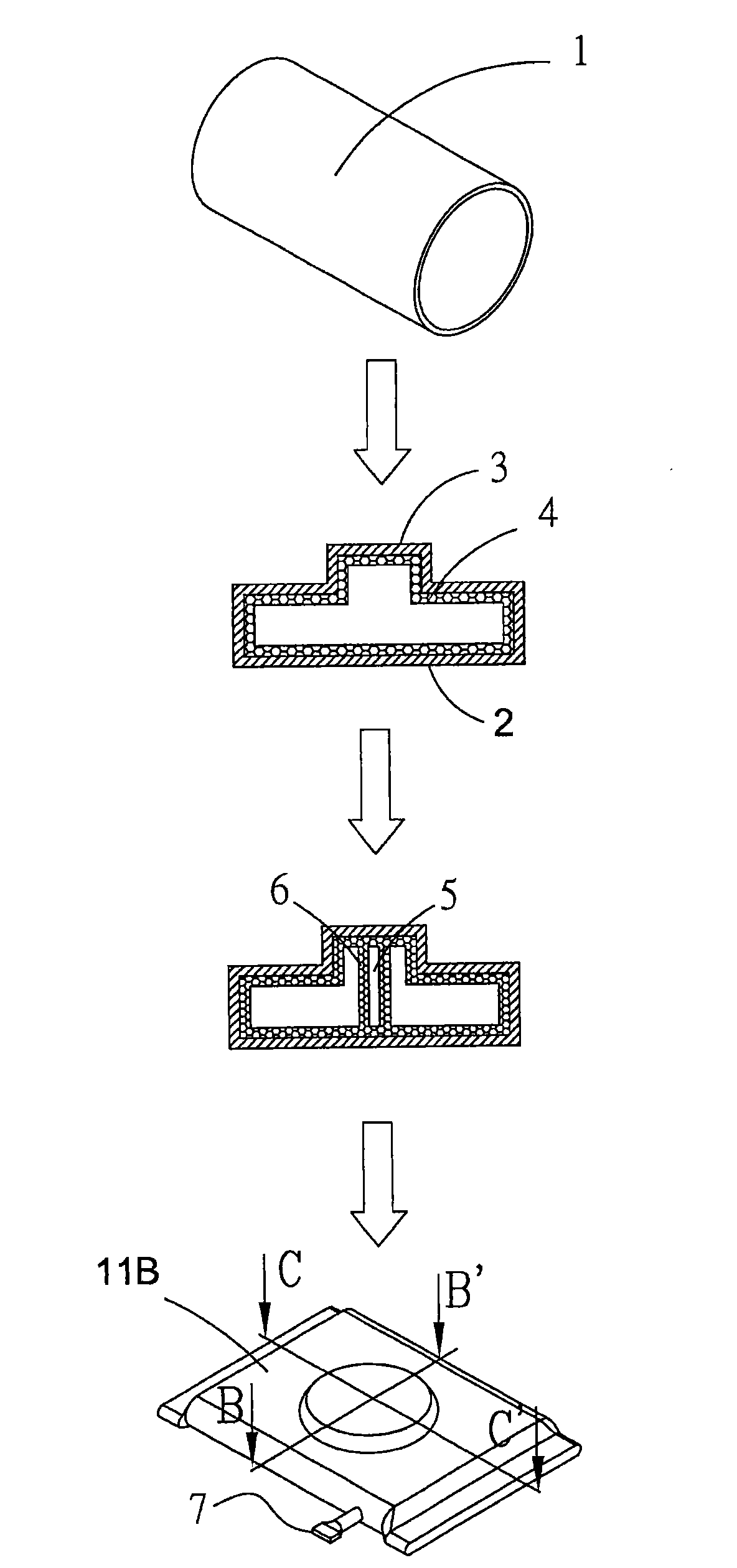

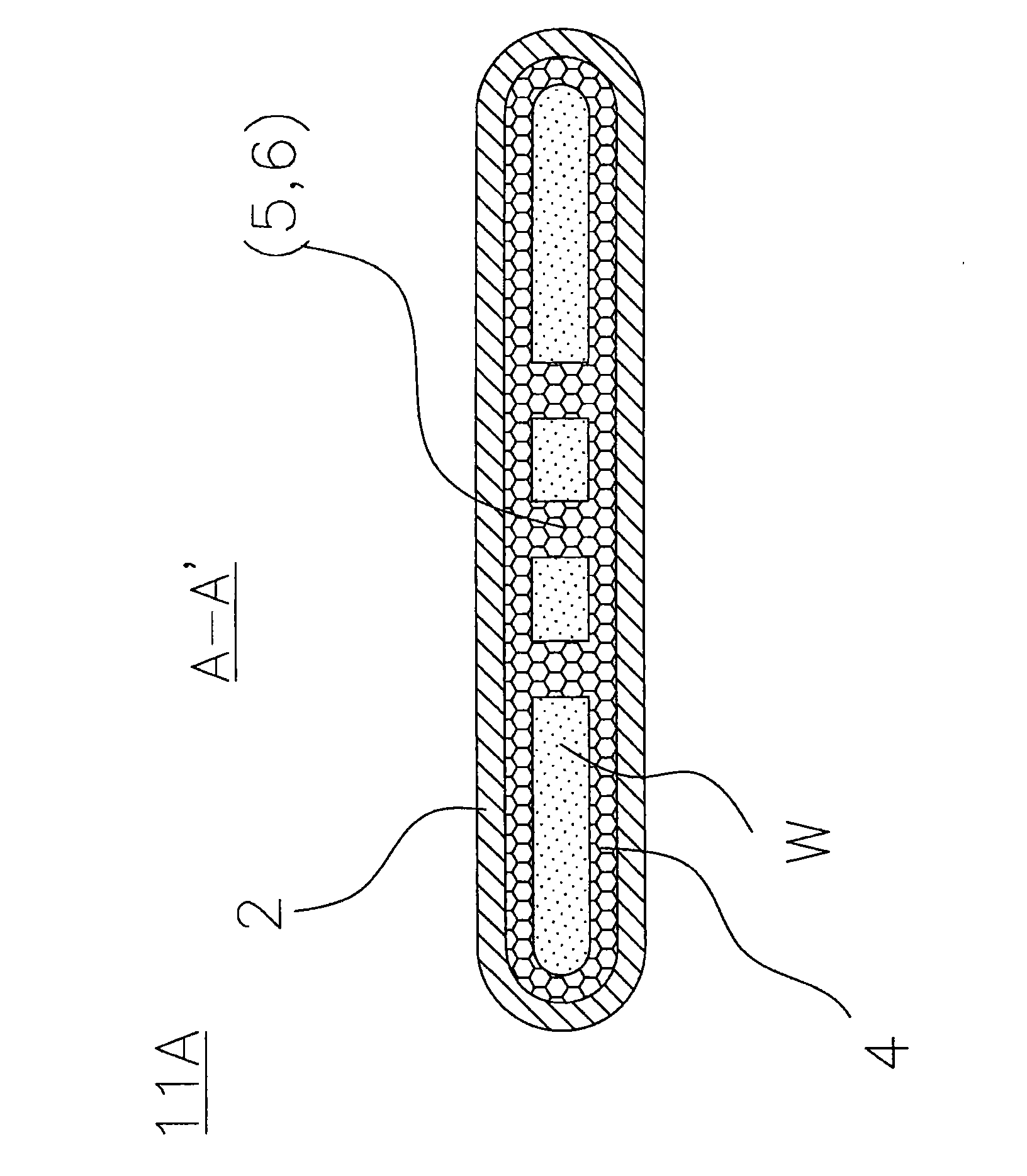

[0030] The manufacturing method of the temperature uniform element of the present invention will be described in detail below, please refer to Figure 1A and Figure 1B , Figure 1A and Figure 1B It is a manufacturing process diagram of two kinds of temperature equalizing elements according to the present invention. Firstly, a flat-plate hollow pipe body 2 is provided, for example, the flat-plate hollow pipe body 2 is formed by stamping a circular pipe material 1, and the cross-sectional shape of the flat-plate hollow pipe body 2 is polygonal, long ellipse shape or long arc shape, and the material of the tube body is aluminum, copper, titanium, molybdenum or other metals with high thermal conductivity. Here, it must be noted that, in addition to being formed by stamping the round tube 1 , the flat hollow tube body 2 can also be directly produced by stamping.

[0031] The interior of the flat-plate hollow tube 2 adopts a sintering method to form a continuous first capillary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com