High performance flexibility heat-resisting material and process thereof

A heat-resistant material and high-performance technology, applied in textiles and papermaking, weft knitting, yarn, etc., can solve the problems that stainless steel fibers cannot meet the quality requirements of high-grade glass, cannot fully meet high-grade glass, and have a short service life. The effect of strength, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the present invention easier to understand, we will describe the present invention in more detail below in conjunction with the accompanying drawings and specific embodiments.

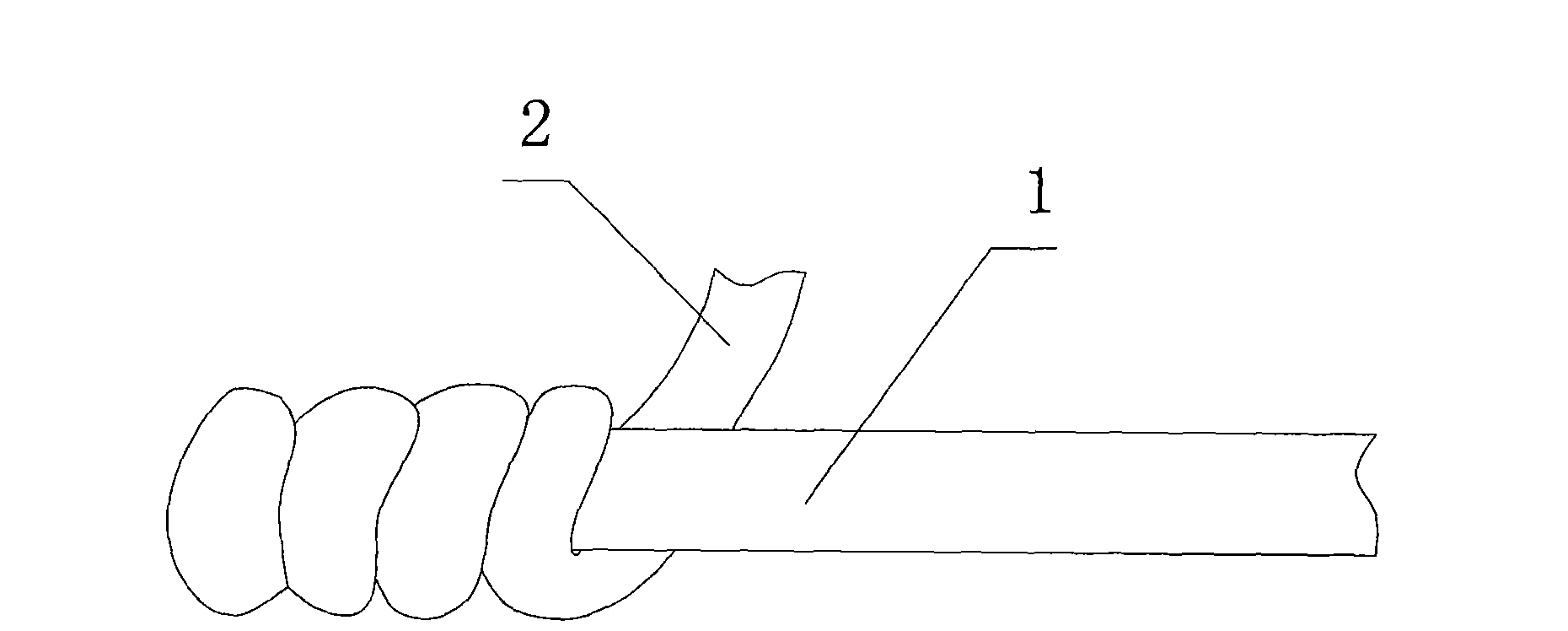

[0009] refer to figure 1 , a high-performance flexible heat-resistant material, which includes PBO staple fiber yarn 2 and stainless steel fiber yarn 1, wherein stainless steel fiber yarn has a count of 5-50Nm and a diameter of 6-50, and PBO staple fiber has a count of 5 ~60Ne, the content of PBO short fiber yarn 2 is 20%~80%, and the content of stainless steel fiber yarn 1 is 80%~20%. During preparation, the stainless steel fiber yarn 1 is first used as the core yarn, and the PBO staple fiber yarn 2 is wound on the stainless steel fiber yarn 1 in a spiral shape to form a covered yarn; then the covered yarn is twisted into two strands; finally, the strand is woven Knitted fabrics, finished products.

[0010] Take the PBO fiber yarn as 45Ne, the stainless steel fiber yarn as 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com