Method for processing zinc oxide ore or zinc oxide secondary resource to prepare superfine active zinc oxide

A technology of activated zinc oxide and secondary resources, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve problems such as ineffective treatment, and achieve the effects of reducing the pressure of three wastes discharge, simplifying the production process, and the process is simple and continuous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

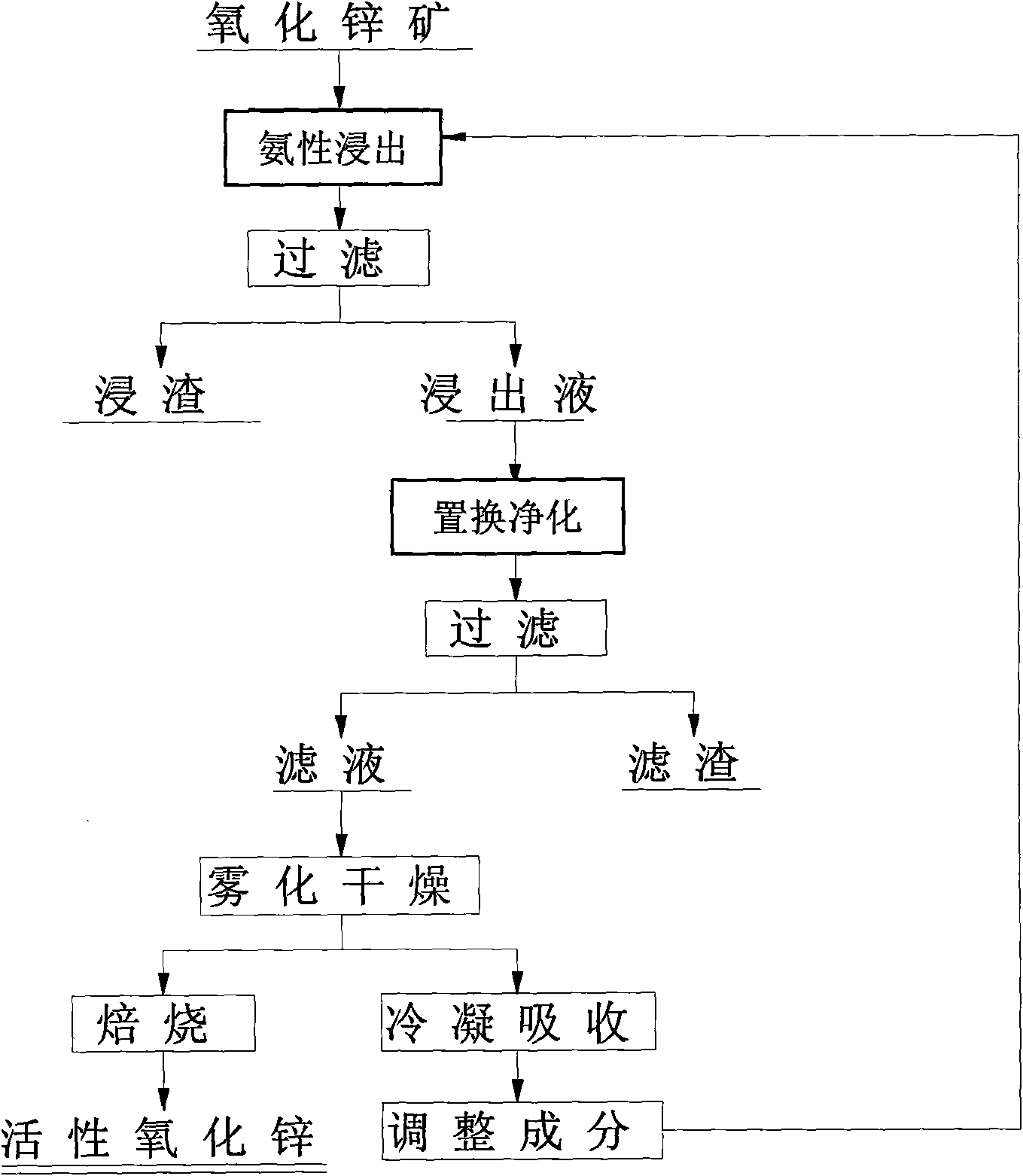

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Zinc oxide composition (%): Zn 19.51, Fe 13.51, Pb 2.30, Cu 0.022, Cd 0.23, S 2.10, As0.098, Sb 0.20, SiO 2 13.78, Al 2 o 3 0.46, CaO 9.31, MgO 0.33, MnO 0.93.

[0046] Prepare first [NH 4 Cl]=5mol / L, [NH 3 ]=5mol / L of leaching agent 1L, weigh 250g of zinc oxide ore, the liquid-solid volume mass ratio is 4:1, at 25°C, leaching for 1h, washing the leaching residue with the same solution as the leaching agent composition when filtering, washing liquid The amount is based on keeping the leachate volume the same as that of the leaching agent. The zinc leaching rate is 83.67%, and the Zn content is 40.81g / L. The leach solution is used as the leaching agent, and then 250g of zinc oxide ore is leached under the same conditions, filtered and washed, incorporated into the lotion, to obtain the second leach solution, the leach solution contains Zn content of 81.25g / L, and the leaching rate reaches 82.93%. The leach solution composition ( g / L): Zn 81.25, Pb 0.8,...

Embodiment 2

[0047] Embodiment 2: zinc oxide ore composition (%): Zn 4.94, Pb 1.74, Cu 0.01, Fe 13.53, Cd 0.29, Co 0.038.

[0048] Prepare first [(NH 4 ) 2 CO 3 ]=2.5mol / L, [NH 3 ] = 5mol / L of leaching agent 1L, weigh 500g of zinc oxide ore, liquid-solid volume mass ratio 2:1, at 35°C, leaching for 1h, after being incorporated into the washing liquid, the volume of the leachate is the same as that of the leachate, and the leachate contains 21.33% zinc g / L; use this leaching solution as a leaching agent, and then leach 500g of zinc oxide ore under the same conditions, and the zinc content in the second leaching solution increases to 42.41g / L; use the second leaching solution as a leaching agent, and carry out under the same conditions The third cycle of leaching, filtering, washing, and adding lotion to obtain the third leachate 1000ml, zinc concentration increased to 63.47g / L, zinc leaching rate 85.21%, leachate composition (g / L): Zn 63.47, Pb 0.06 , Cu 0.12, Cd 0.71. Add zinc powder ...

Embodiment 3

[0049] Embodiment 3: The raw material is zinc oxide secondary resource, i.e. secondary zinc oxide soot, composition (%): Zn 45.76, Pb 7.45, Cd0.47, Fe4.09, In0.044, Mn0.40, Cu0.072, Ag0 .0044, Cl0.04, F0.84, Sb0.34, As1.28. Prepare first [NH 4 ·HCO 3 ]=2mol / L, [NH 3 ] = 1L of leaching agent of 6mol / L, weigh 250g of zinc oxide soot, the liquid-solid volume mass ratio is 4:1, and leaching for 1h at 20°C. %, leachate composition (g / L): Zn 106.69, Pb 0.45, Cu 0.06, Cd 0.82, As 0.046, Sb 0.0058. Add zinc powder according to 4 times the theoretical amount of zinc powder required to replace Cu, Cd, and Pb, stir for 0.5h, and temperature 50°C. The purified liquid is reacted in a high-efficiency spray dryer to form powder A. The reaction conditions are: inlet temperature 450°C, outlet temperature 280°C, feed rate 50mL / min, feed zinc concentration 100g / L. Part of the basic zinc carbonate has not reacted completely, and the powder A is a mixture of basic zinc carbonate and zinc oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com