Method for preparing minor-diameter carbon nanotube array on surface of flaky material

A carbon nanotube array and sheet material technology, which is applied in the field of new materials and their preparation, can solve the problem of carbon nanotube diameter control strategy not being strictly controlled, and achieves the effects of easy industrial scale-up, simple operation, and easy serialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

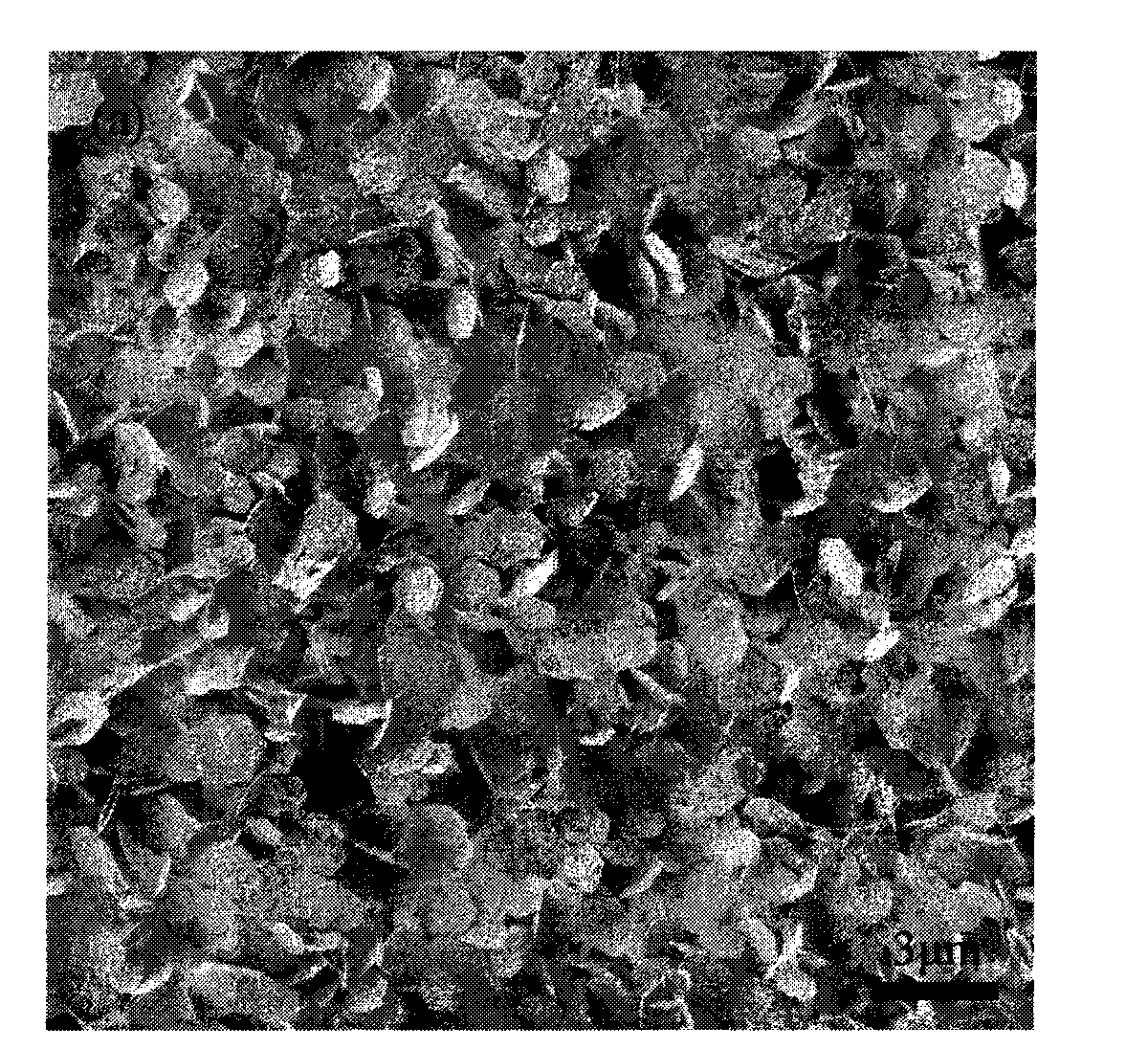

[0031] Example 1: Preparation of small-diameter carbon nanotube arrays in a fixed bed of FeMgAl layered double hydroxyl metal oxides

[0032] 20mgFe content was 10%, CO 3 2- Anionic FeMgAl layered double hydroxy metal oxides are used as catalysts in a fixed-bed reactor, and a mixed gas of hydrogen and argon is introduced to reduce the catalyst at a temperature of 600 ° C with a reduction space velocity of 1 hr -1 , the volume ratio of hydrogen to carrier gas is 1:10; the average particle size of metal particles after reduction is 5nm, and the density is about 10 10 grain / cm 2 . The temperature of the reactor was raised to 750°C, and a mixed gas of ethylene, hydrogen and argon was introduced, wherein the volume ratio of hydrogen: ethylene: argon was 0.1:1:10, and the space velocity of the reaction process was 2000hr -1 , the gas velocity is 0.5m / s. After 30 minutes, the hydrogen and carbon source ethylene were turned off, the reactor was cooled to room temperature under an...

Embodiment 2

[0033] Example 2: Preparation of small-diameter carbon nanotube arrays in a CoMgAl layered double hydroxy metal oxide fluidized bed

[0034] With 0.5g Co content as 20%, CO 3 2- The anionic CoMgAl layered double hydroxy metal oxide is used as a catalyst in a fluidized bed reactor, and a mixed gas of hydrogen and argon is introduced to reduce the catalyst at a temperature of 700 ° C with a reduction space velocity of 2 hr -1 , the volume ratio of hydrogen to carrier gas is 1:0.1; the average particle size of metal particles after reduction is 7nm, and the density is about 10 11 grain / cm 2 . The temperature of the reactor is raised to 650°C, and a mixed gas of propylene, hydrogen and argon is introduced, wherein the volume ratio of hydrogen: propylene: argon is 0.1:1:0.1, and the space velocity of the reaction process is 5000hr -1 , the gas velocity is 0.05m / s. After 30 minutes, the hydrogen and carbon source propylene were turned off, the reactor was cooled to room tempera...

Embodiment 3

[0035] Example 3: Preparation of small-diameter carbon nanotube arrays in a fixed bed of CoAl layered double hydroxy metal oxides

[0036] 0.5g Co content 30% CO 3 2- The anionic CoAl layered double hydroxy metal oxide is used as a catalyst in a fixed-bed reactor, and a mixed gas of hydrogen and nitrogen is introduced to reduce the catalyst at a temperature of 600 ° C, and the reduction space velocity is 0.2 hr -1 , the volume ratio of hydrogen to carrier gas is 1:20; the average particle size of metal particles after reduction is 15nm, and the density is about 10 8 grain / cm 2 . The temperature of the reactor is raised to 650°C, and a mixed gas of ethanol, hydrogen and nitrogen is introduced, wherein the volume ratio of hydrogen: ethanol: nitrogen is 1:1:10, and the space velocity of the reaction process is 100hr -1, the gas velocity is 0.5m / s. After 30 minutes, the hydrogen and carbon source ethanol were turned off, the reactor was cooled to room temperature under nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com