Standard magnetic suspension hybrid bearing-supported rotor and high-speed induction electrical rotating machine

An electric rotating and hybrid bearing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of high cost, soft end ring and bar end material, complicated process, etc., and achieve the effect of stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

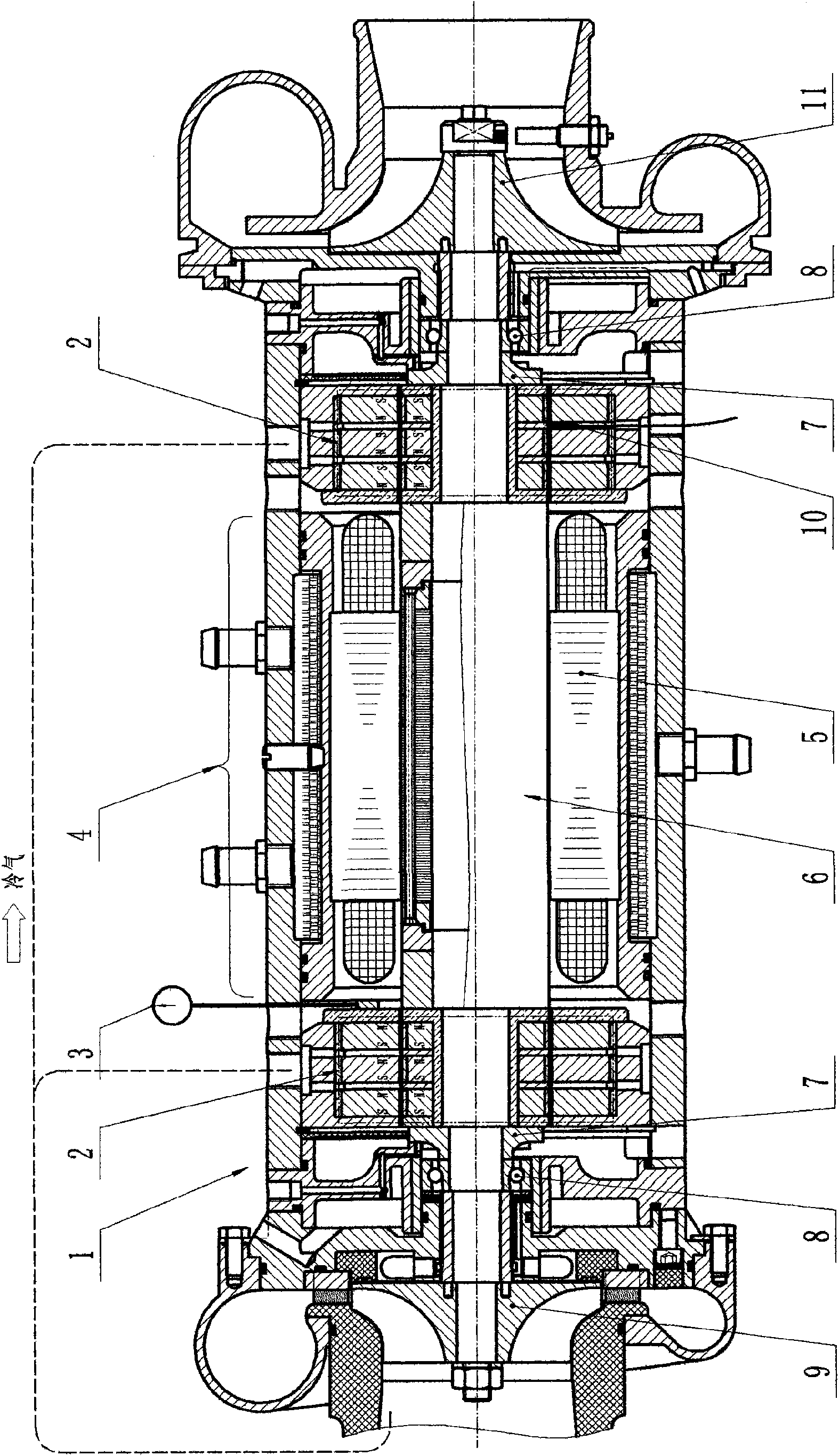

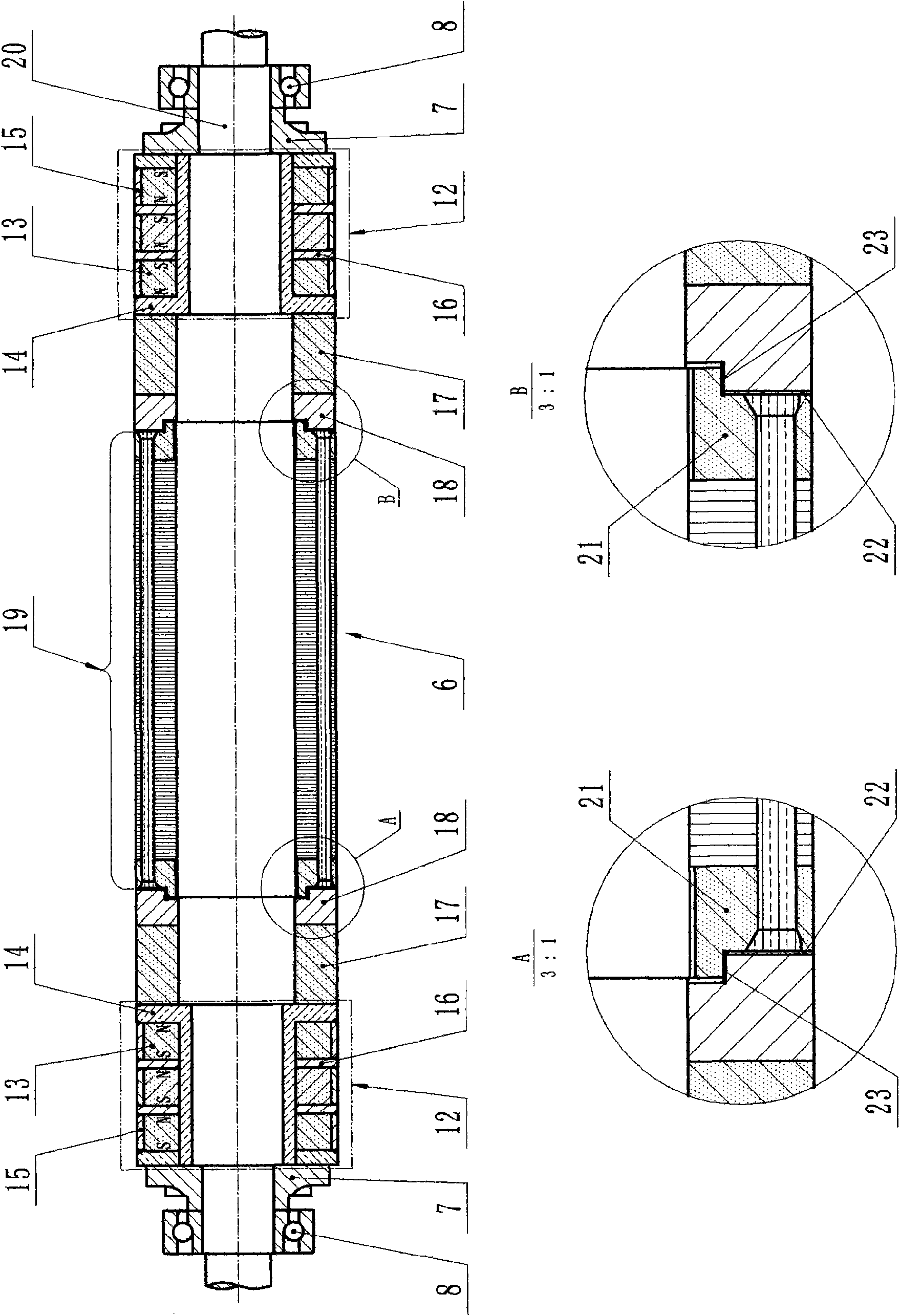

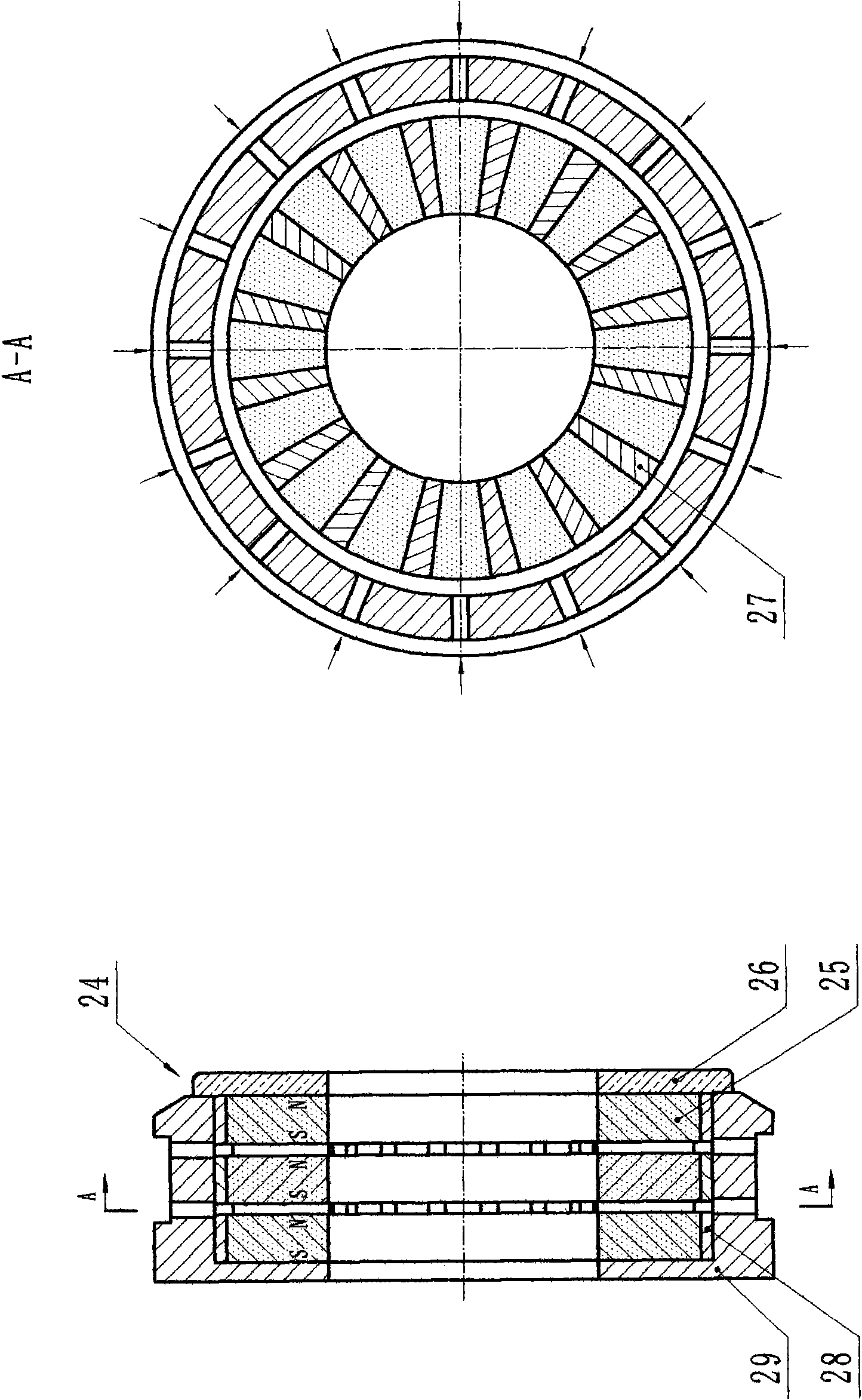

[0018] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. figure 1 It is shown as a front view of an air refrigerator 1 directly driven by an electric motor including a quasi-maglev hybrid bearing supported rotor 6 of the present invention. figure 1 Among them, the air refrigerator 1 includes an electric motor 4 in its middle. The electric motor 4 includes a rotor 6 and a stator 5 supported by quasi-maglev hybrid bearings. The rotor 6 uses a pair of three sets of permanent magnetic radial bearings 2 as the main support, and a pair of angular contact ball bearings 8 as the radial auxiliary support, and together with a pair of sliding thrust bearings 7 bear the axial thrust. There are fan blades on the sliding thrust bearing 7 to cool the angular contact ball bearings 8. When the low-pressure lubricating oil is sprayed onto the high-speed rotating sliding thrust bearing 7, the fan blades on it will beat the lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com