Grid alloy and manufacturing method and applications thereof

A manufacturing method and alloy technology, which are applied in lead-acid battery electrodes, electrode carriers/current collectors, lead-acid batteries, etc., can solve the problems of grid fracture and extension, poor permeability, poor bonding ability of positive active materials, etc. Achieve the effect of high hydrogen evolution overpotential and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

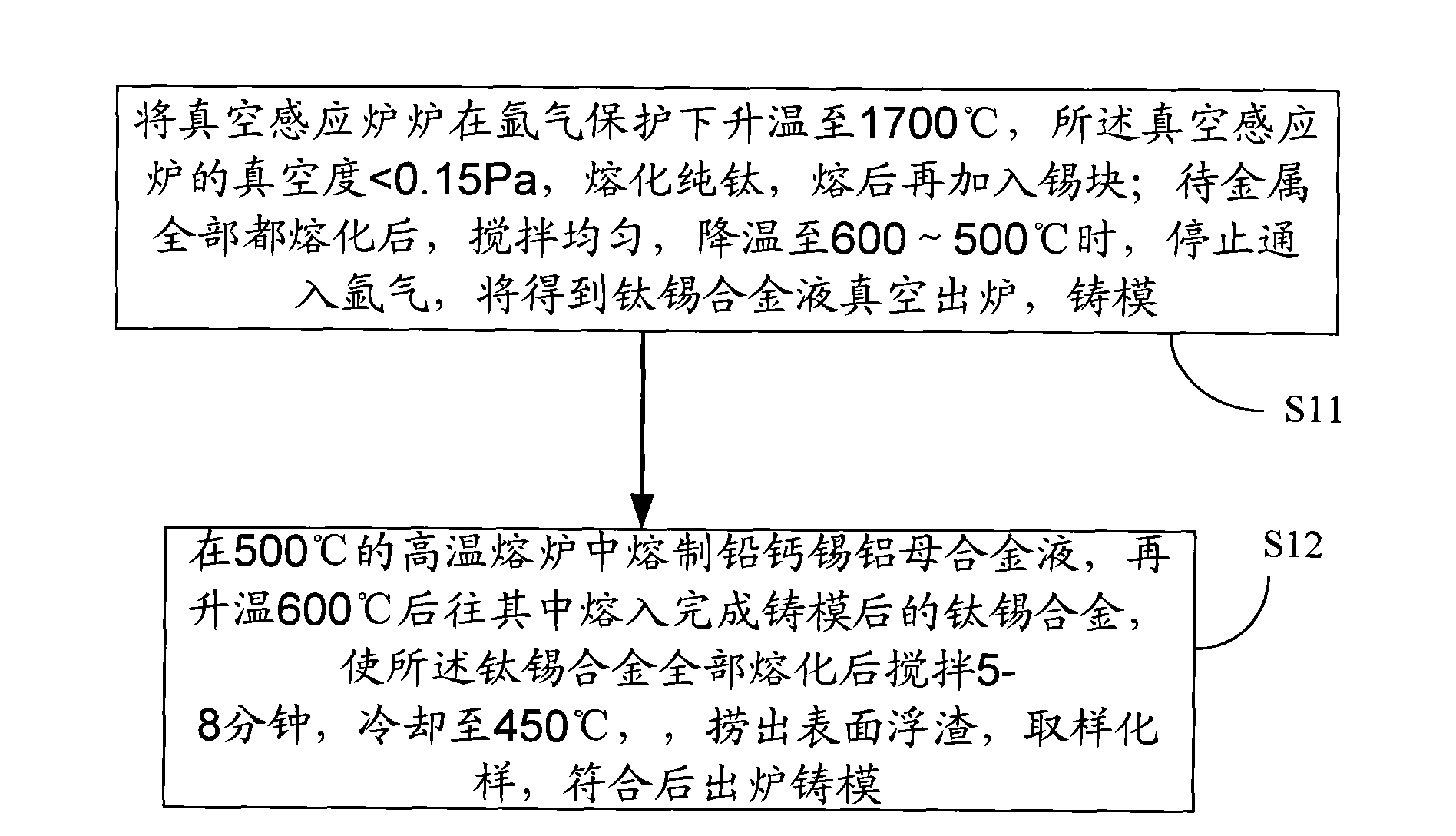

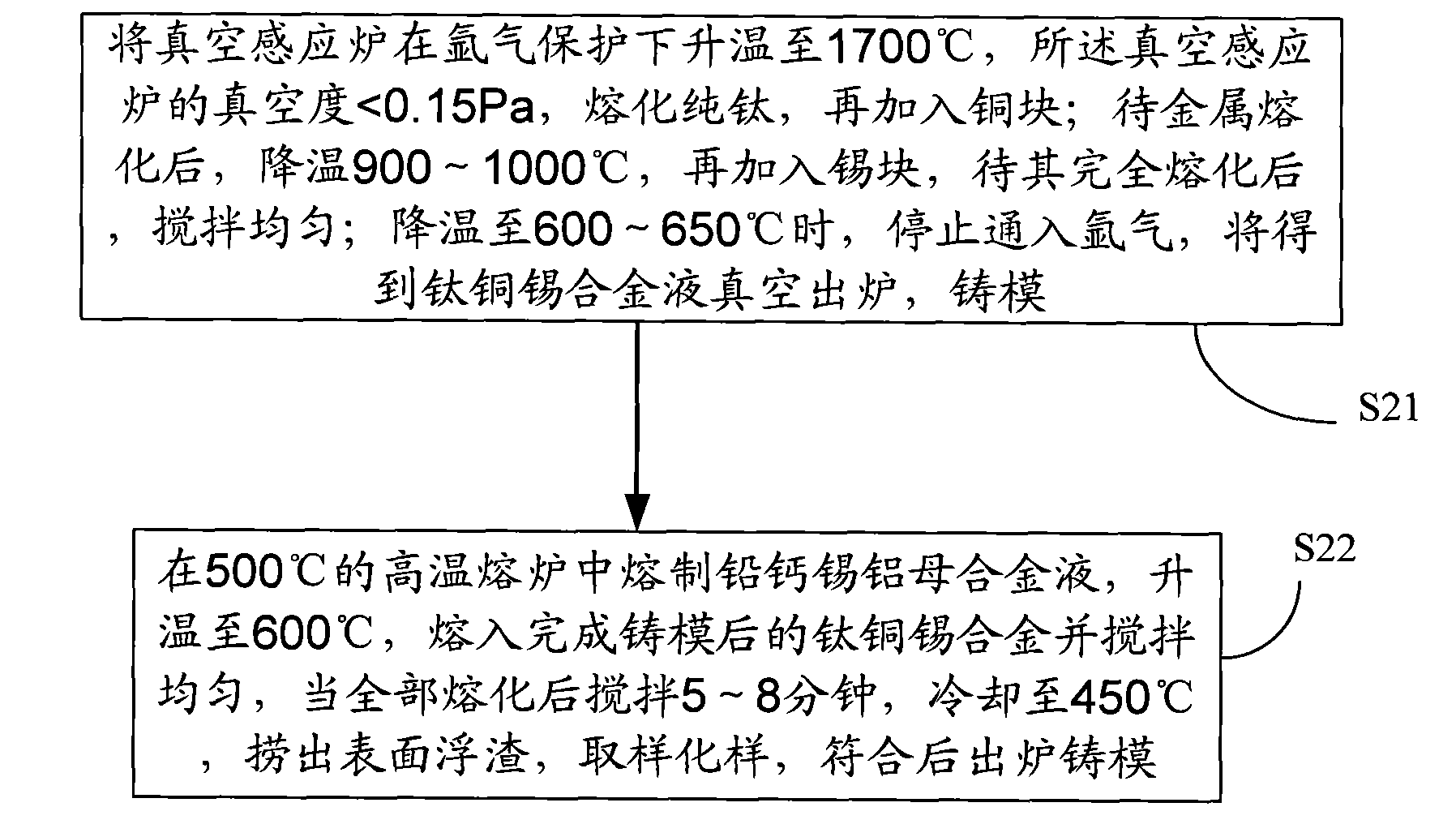

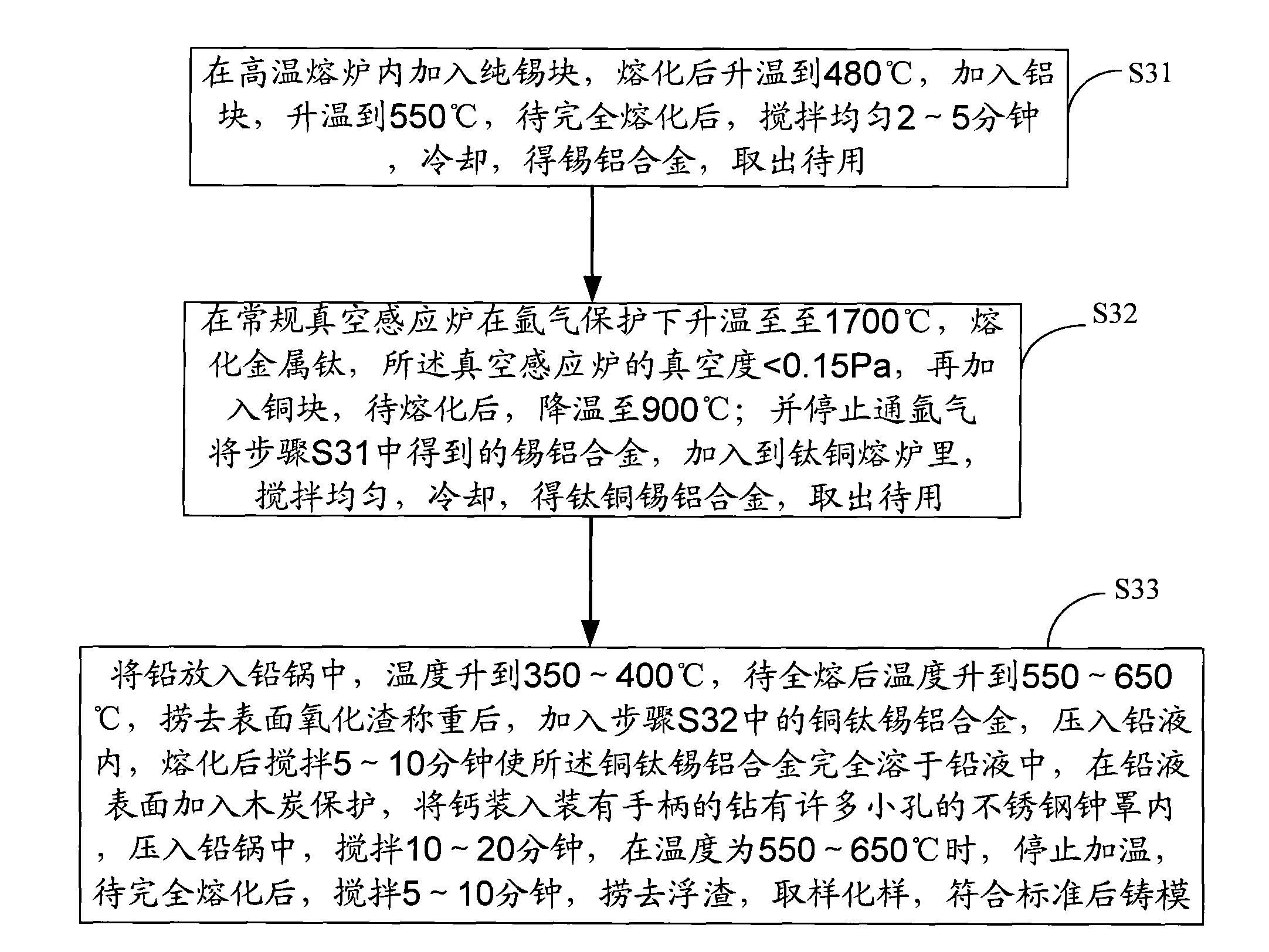

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 provides a grid alloy, which may include: lead Pb, calcium Ca, tin Sn, aluminum Al and titanium Ti, and its mass percentage content is as follows:

[0028] Calcium Ca: 0.06~0.09%;

[0029] Tin Sn: 0.05~0.9%;

[0030] Aluminum Al: 0.005~0.053%;

[0031] Titanium Ti: 0.00225~0.068%;

[0032] Lead Pb: balance;

[0033] The purity of the titanium Ti, tin Sn, aluminum Al and lead Pb are all 99.9% or above.

[0034] Of course, in actual situations, the specific content of the grid alloy can also be shown in Table 1:

[0035] Table 1:

[0036]

Example

11

Example

12

Example

13

Example

14

Example

15

Example

16

Calcium Ca

(%)

0.06

0.07

0.075

0.08

0.085

0.09

Tin Sn

(%)

0.9

0.7

0.5

0.3

0.1

0.05

Aluminum Al

(%)

0.005

0.0082

0.03 ...

Embodiment 2

[0040] A grid alloy provided in Example 2, the grid alloy may include: lead Pb, calcium Ca, tin Sn, aluminum Al and titanium Ti, and its mass percentage content is as follows:

[0041] Calcium Ca: 0.06~0.09%;

[0042] Tin Sn: 0.05~0.9%;

[0043] Aluminum Al: 0.005~0.053%;

[0044] Titanium Ti: 0.00225~0.068%;

[0045] Copper Cu: 0.0045~0.176%;

[0046] Lead Pb: balance;

[0047] Among them, the purity of titanium Ti, tin Sn, aluminum Al, lead Pb and copper Cu are all 99.9% or above.

[0048] Of course, in actual situations, the specific content of the grid alloy can be shown in Table 2:

[0049] Table 2:

[0050]

Example

twenty one

Example

twenty two

Example

twenty three

Example

twenty four

Example

25

Example

26

Calcium Ca

(%)

0.06

0.07

0.075

0.08

0.085

0.09

Tin Sn

(%)

0.9

0.7

0.5

0.3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com