Large-scale solid profile hot extrusion mould of medium extruder

A new type of die and extruder technology, applied in metal extrusion dies and other directions, can solve the problems of small extrusion ratio, angular slump angle of profiles, and heavy profile meters, so as to slow down the flow rate, increase the extrusion force, Guaranteed effect of density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

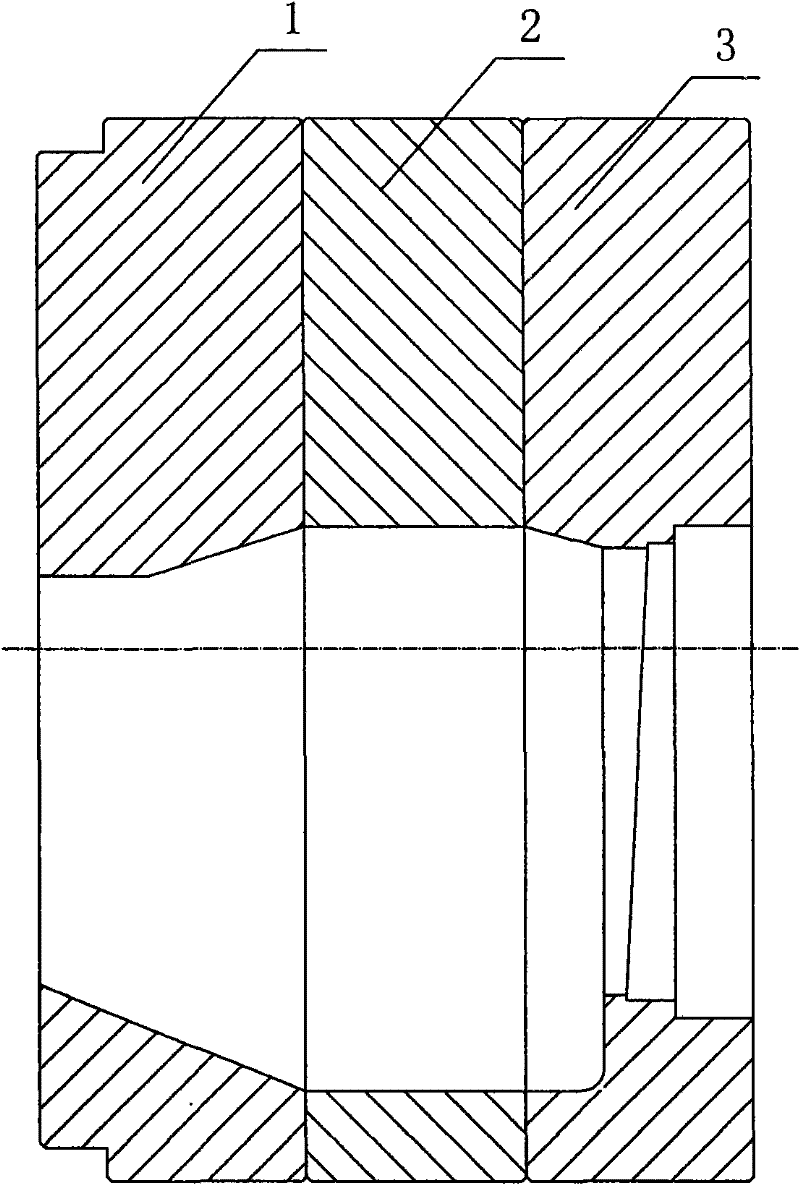

[0024] see figure 2 and image 3 , figure 2 It is a schematic diagram of the front structure of a new mold for hot extrusion of a large solid profile on a medium-sized extruder of the present invention. image 3 for figure 2 A-A cut-away diagram. Depend on figure 2 and image 3 It can be seen that the new mold for hot extrusion of large solid profiles on the medium-sized extruder of the present invention is formed by superimposing the front deflector 1, the secondary deflector 2 and the die surface 3 successively from front to back.

[0025] see Figure 4 and Figure 5 , Figure 4 It is a schematic diagram of the front structure of the front deflector of the present invention. Figure 5 for Figure 4 The B-B section diagram. Depend on Figure 4 and Figure 5 It can be seen that the front deflector 1 of the present invention includes a first central feed hole 11, and the upper and lower walls of the first central feed hole 11 are divided into two parts: a front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com