Breakage prediction method, calculation processing device, program, and recording medium

A prediction method and program technology, which can be used in measurement devices, electrical digital data processing, special data processing applications, etc., can solve problems such as difficulty in dangerous parts of fracture, and achieve the effects of reducing dependence, weight, and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0152] Examples are given below to describe the present invention. A forming test was performed to simulate flange rising forming by dividing the shape of a plain plate from a generally performed hole reaming test with a cylindrical punch. That is, for an object provided with a hole (diameter 60mm, or 40mm, 20mm) in the center of a 180mm quadrilateral plain plate, such as Image 6 Shown cut off as 1 / 4, as in Figures 7A-7C As shown, after the workpiece 4 is constrained by the anti-wrinkle device 2 on the 106φ die 1 with a shoulder R of 5mm, it is formed by a 100φ cylindrical flat bottom punch 3 with a shoulder R of 10mm. At this time, the flange rising height 5 is about 20 mm when the hole diameter is 60 mm, about 30 mm when the hole diameter is 40 mm, and about 40 mm when the hole diameter is 20 mm. As the material, a 440MPa grade cold-rolled steel sheet with a thickness of 1.6mm was used. In the experiment, molding was performed in groups of 4 sheets. The results are sum...

Embodiment 2

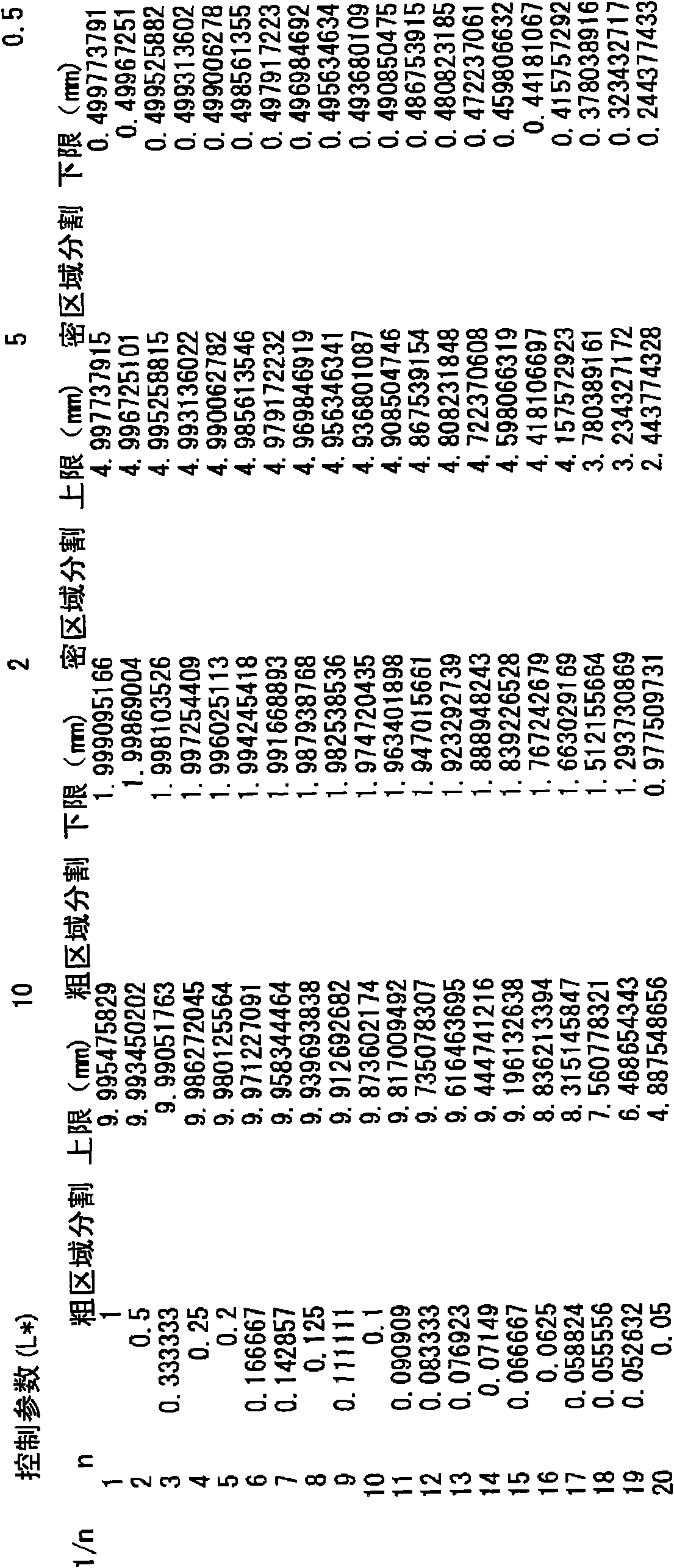

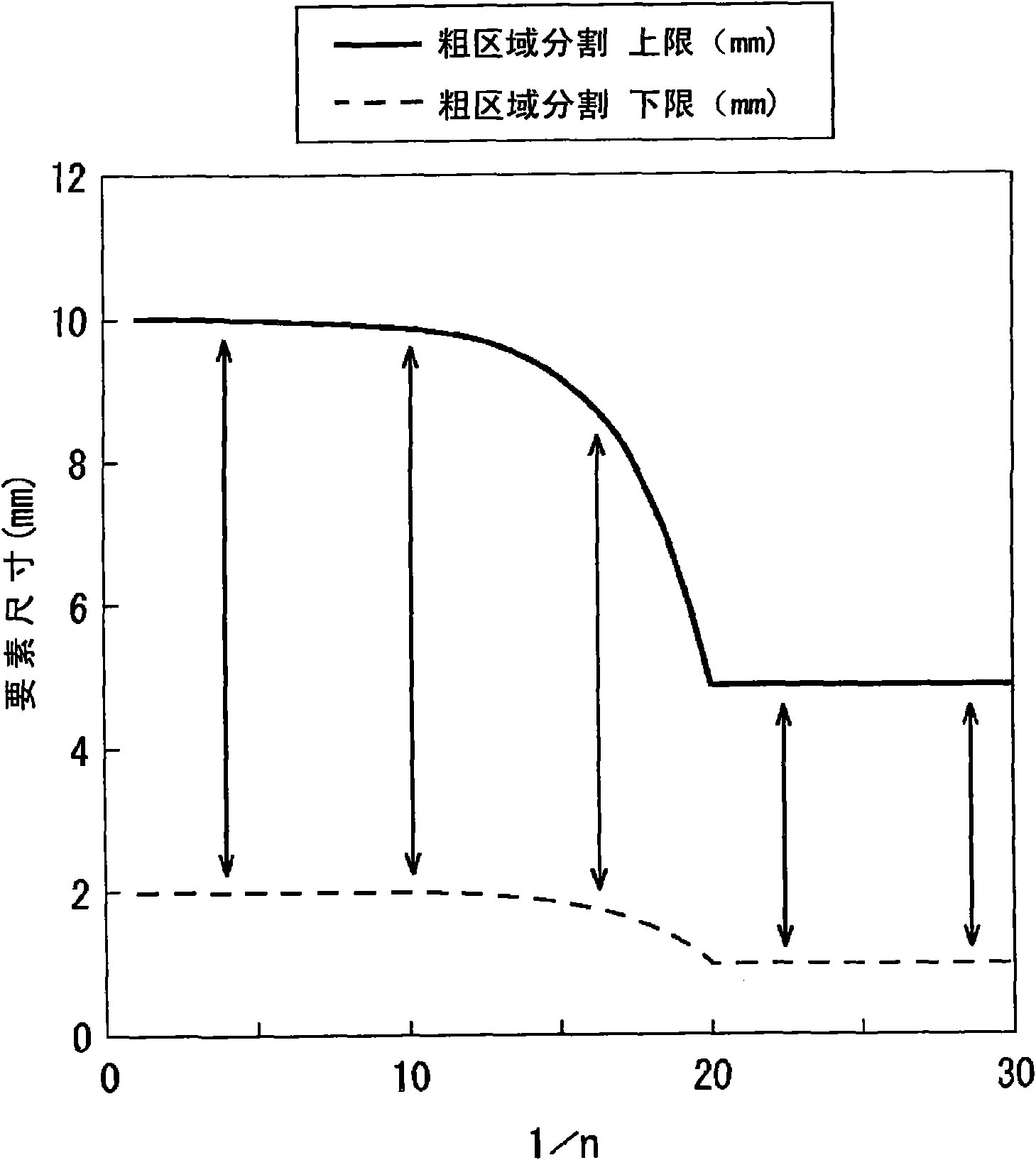

[0161] Using the analysis results of the hole diameter of 60 mm and the small element size (approximately 2 mm) in Example 1, by combining two or more adjacent elements and comparing the difference before and after the combination to evaluate the deformation gradient, it was investigated whether fracture judgment can be performed.

[0162] Element division and shape analysis were performed in the same manner as in Example 1 when the element size was small ( Figure 8A ).

[0163] Based on the shaping analysis result, the analysis value of the element (in particular, the vicinity of the element whose analysis value has a peak value) is output together with its position information. This data is input to a computer for data analysis, and the arithmetic mean of the analysis values is calculated for every 2 to 5 adjacent binding elements selected this time, and the difference from the maximum value of the analysis values in the original analysis is calculated.

[0164] The di...

Embodiment 3

[0166] Under the test conditions of Example 1 with a hole diameter of 40 mm, it was investigated whether fracture prediction of materials of various strengths can be performed. The materials used are steel plates from mild steel to 980 MPa class shown in Table 2. The plate thickness is 1.6mm.

[0167] As a result of the experiment, in the 980 MPa grade steel plate, the seam fracture occurred in the center of the portion where the flange stood up. The finite element method analysis was performed under the same conditions as the experiment. The element size is analyzed in two types, approximately 2 mm and approximately 4 mm. end split as Figure 8A and Figure 8B As shown, in order to connect smoothly without unevenness at the ends, and to ensure that the size of the element changes along the ends, automatic division is performed by a computer after specifying the number of divisions of the circumference. Forming analysis and calculation of the maximum principal strain and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com