Automatic continuous band solid-liquid segregation apparatus

A technology of solid-liquid separation and continuous belt, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of high vacuum requirement, high cost of rubber drainage belt, and reduce energy consumption, etc., to achieve high degree of automation, Pure solid products, reducing the effect of harm to the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

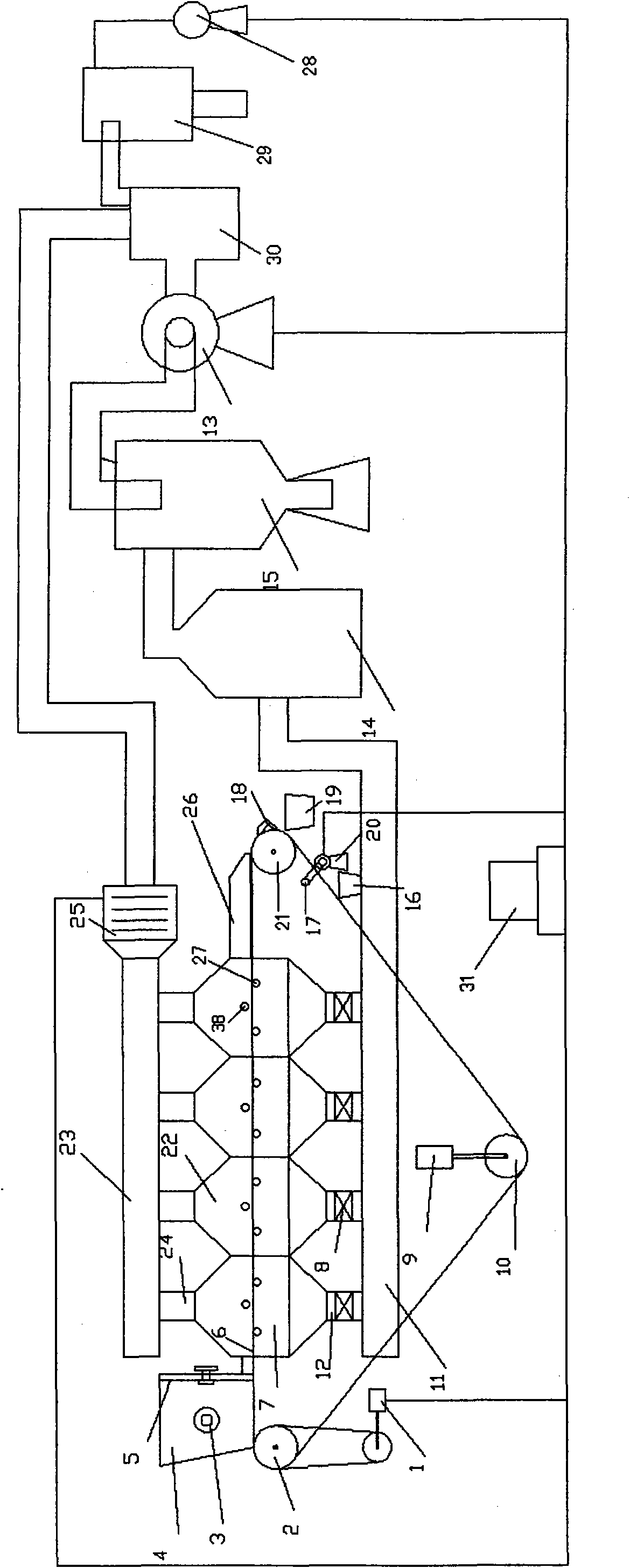

[0026] The invention includes a material unloading system, a conveying system, a material unloading system, an air inlet system, an air induction system, a gas-liquid separation system, a control system and an air purification system.

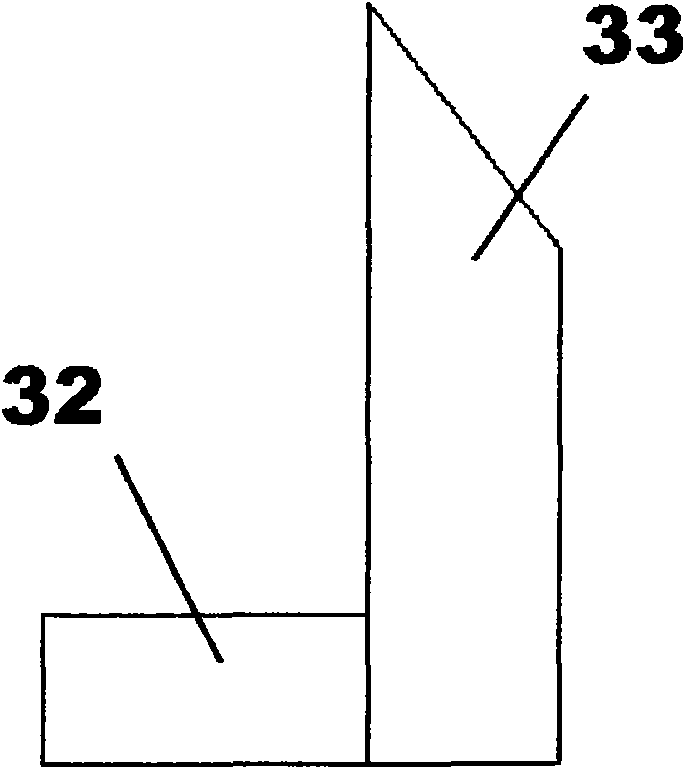

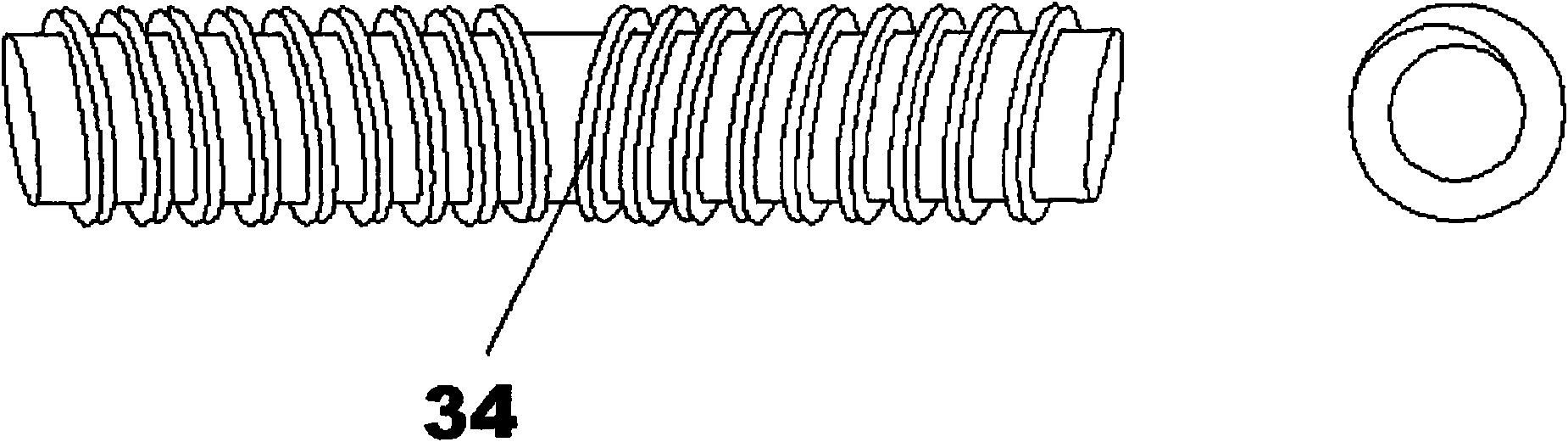

[0027]The feeding system is composed of a lowering hopper 4, a distributor 3 and a thickness-adjusting gate 5. The thickness-adjusting gate 5 is arranged on the inner side of the lowering hopper wall on the side of the advancing direction of the conveyor belt 6, and the distributor 3 is arranged in the middle of the lowering hopper 4. , The top of the conveyor belt 6. The distributor 3 is a round rod, and the round rod is provided with helical blades 34 that rotate in reverse from the middle to both sides. The thickness-adjusting gate 5 is fixed on the inner side of the lower hopper wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com