Coating agent

一种涂布剂、异氰酸酯基的技术,应用在涂层、蜡涂料、其他橡胶涂料等方向,能够解决耐磨擦、磨损特性降低、涂布剂层耐性出现问题等问题,达到优异密封性、安装作业性优异、减少磨损的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

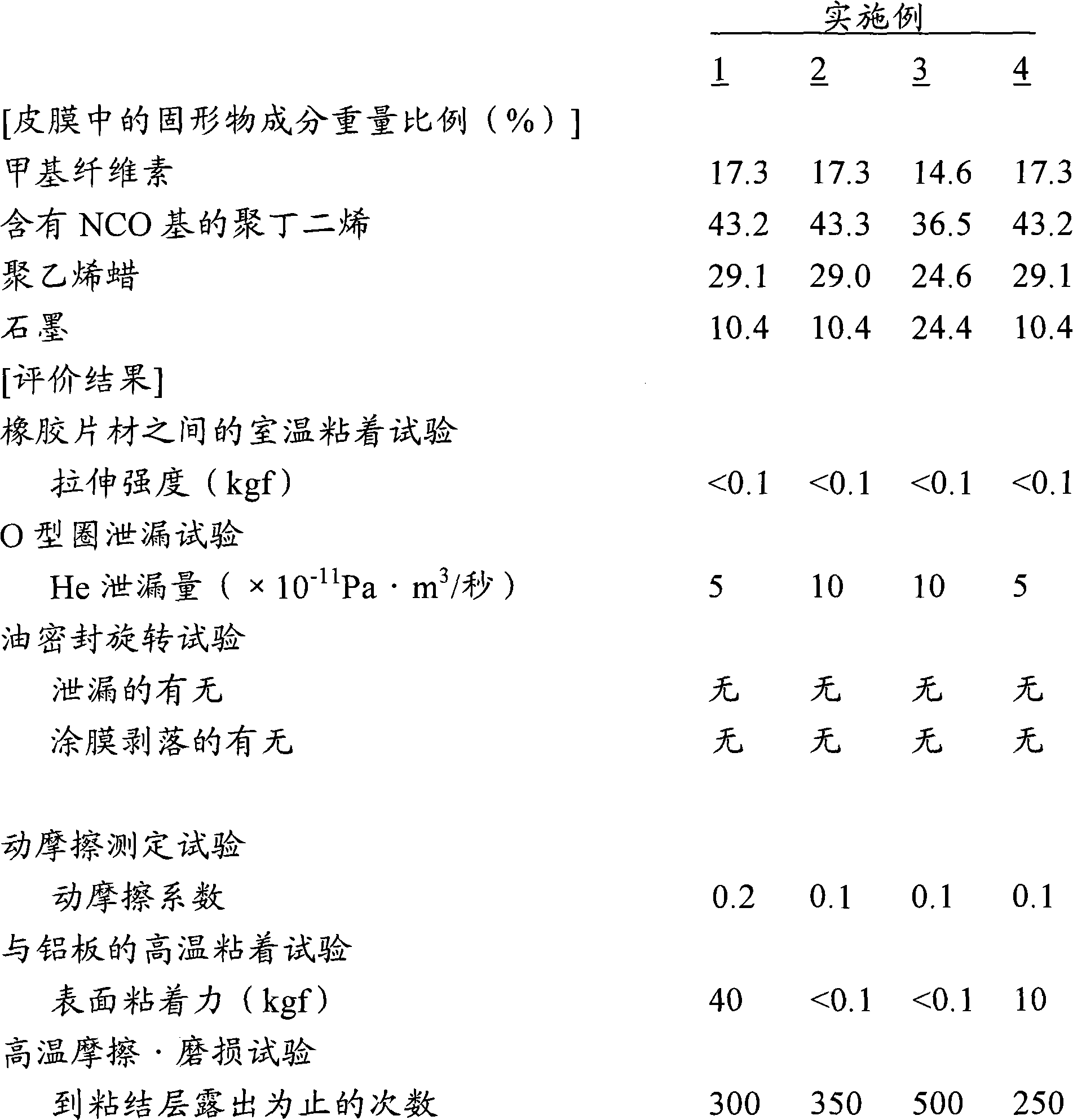

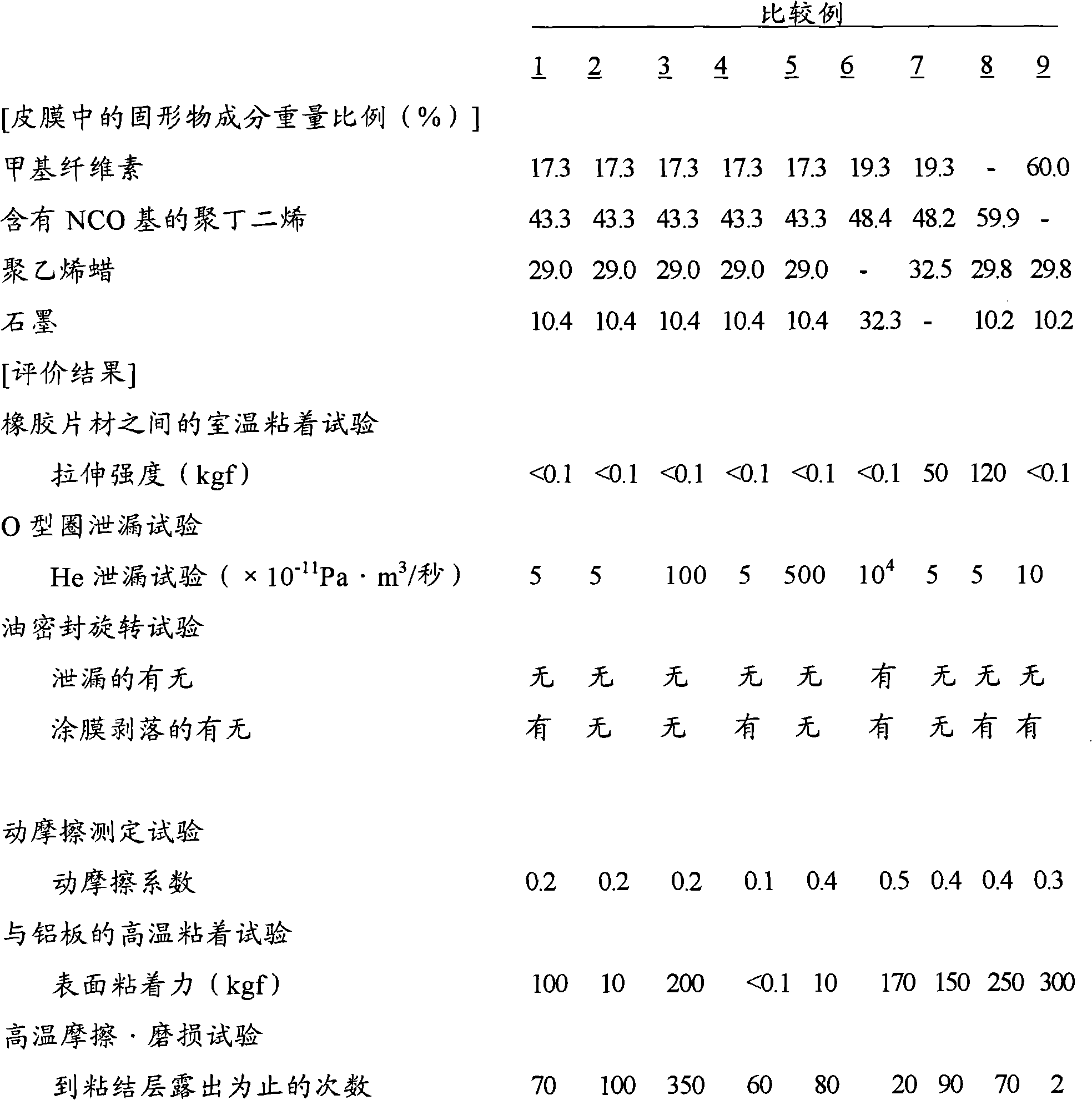

Examples

Embodiment 1

[0052] Methylcellulose (Shin-Etsu Chemical) 10% toluene solution 130 (13) parts by weight

[0053] 1,2-polybutadiene containing isocyanate group 65 (32.5) parts by weight

[0054] (Nippon Soda product TP1001; 50% butyl acetate solution)

[0055] Sasol wax 73 (10.95) parts by weight

[0056] (Sasol’s product, softening point 110°C, particle size below 2 μm; 15% toluene solution)

[0057] Oleamide 73 (10.95) parts by weight

[0058] (Nippon Kasei product Diamid 0-200, softening point 75°C, particle size below 2μm; 15% toluene solution)

[0059] Graphite (Nichiden Carbon Co., Ltd. product C-1) 7.8 (7.8) parts by weight

[0060] Toluene 653 parts by weight

[0061] Mix the components of the above coating agent (the solution concentration is weight %, the value in brackets is the weight part of solid content) and mix them on the compression-molded sheet (60×25×2mm), O-ring (inner diameter: 119.6mm, thick 7 mm in diameter, identification number P120) and oil seals (85 mm in in...

Embodiment 2

[0086] In embodiment 1, use 1,2-polybutadiene (Nippon Soda product G-1000) 19.5 (19.5; Hydroxyl value 70 (KOHmg / g)) weight part and isocyanate (Bayer company's product Desmodur R) 13 (13) parts by weight (7% isocyanate content) of the reaction product to replace 1,2-polybutadiene containing isocyanate groups, and the amount of toluene was changed to 685 parts by weight.

Embodiment 3

[0088] In Example 1, the amount of graphite was changed to 21.7 (21.7) parts by weight, and the amount of toluene was changed to 825 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com