Core body of flat-plate heat exchanger for fresh air ventilator

A fresh air ventilator, flat-plate technology, applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of limiting the popularity of fresh air ventilators, low heat exchange efficiency, large volume and weight, etc. Achieve the effects of simple structure, improved heat transfer efficiency and high heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is further described:

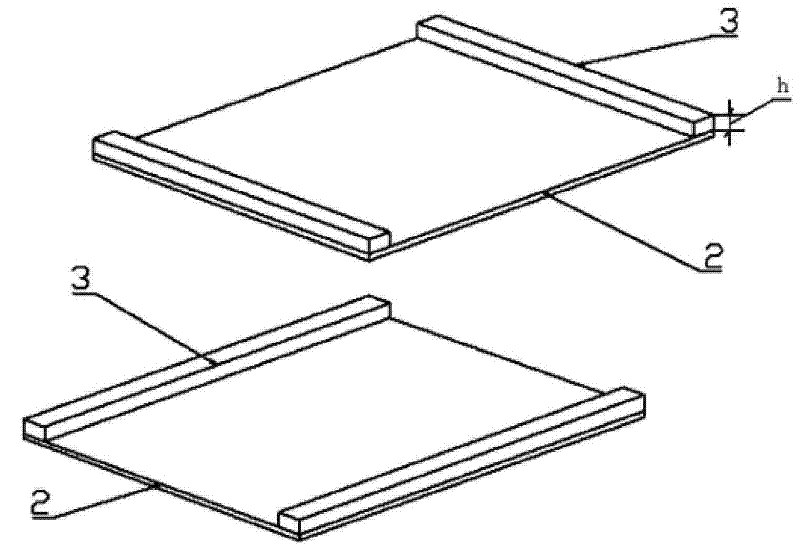

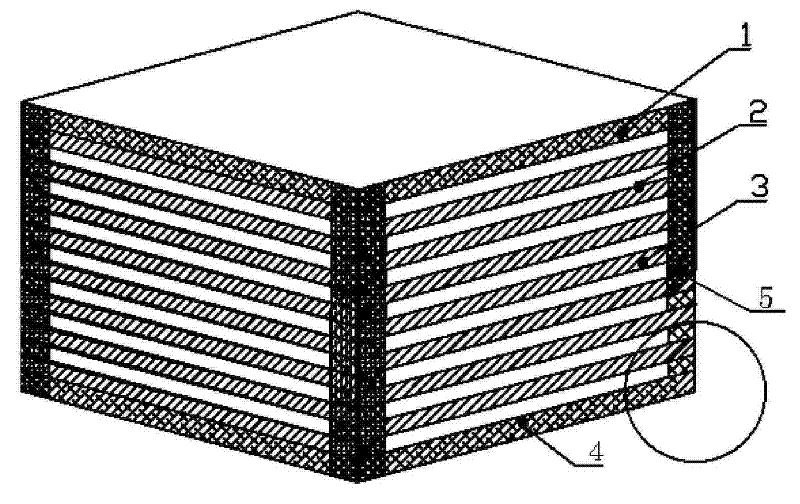

[0024] A flat plate heat exchanger core for a fresh air ventilator, comprising a quadrangular plastic heat exchange membrane 2, a top plate 1 having the same shape as the plastic heat exchange membrane, and a top plate 1 having the same shape as the plastic heat exchange membrane. The bottom plate 4 and the sealing strip 3 are fixedly connected on the upper surface near the two opposite sides of the odd-numbered plastic heat exchange membrane to the lower surface near the two opposite sides of the even-numbered plastic heat exchange membrane through the seal , constituting the first airflow passage, the upper surface near the other two opposite sides of the even-numbered plastic heat exchange membrane passes through the seal and the near two opposite sides of the other odd-numbered plastic heat exchange membrane The lower surface of the airflow channel is fixedly connected to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com