Flat total-heat heat exchange core body for fresh air ventilator

A fresh air ventilator and flat panel technology, which can be used in household heating, household heating, indirect heat exchangers, etc., can solve the problem of restricting the development and application of fresh air ventilators, cross-flow heat transfer is not as good as counter-flow, and restricts heat transfer Core efficiency and other issues, to achieve the effect of simple structure, lower thermal resistance of dirt, and less dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

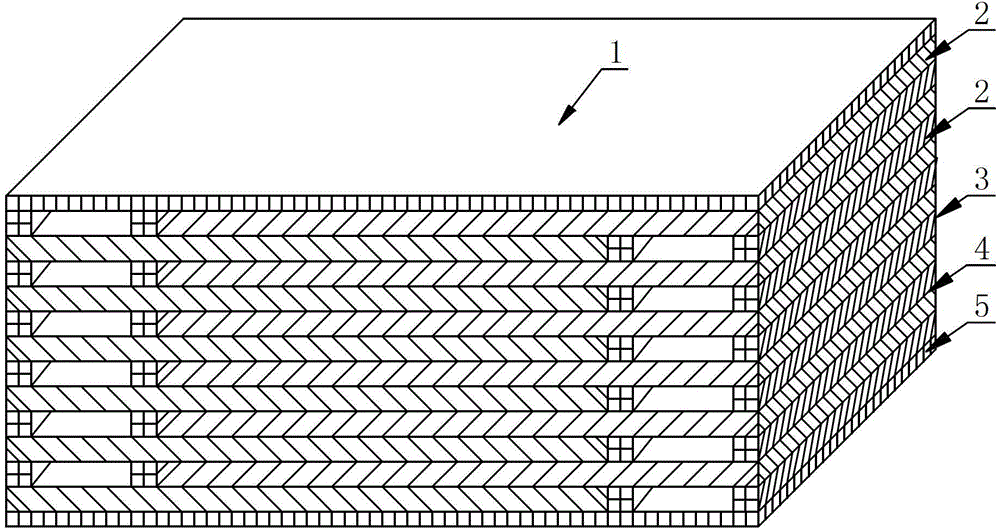

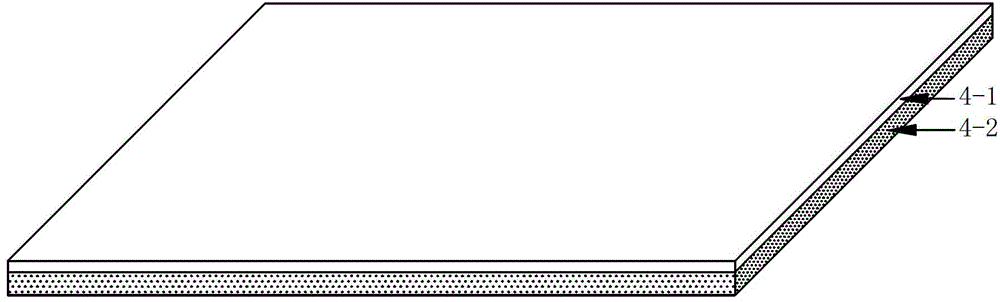

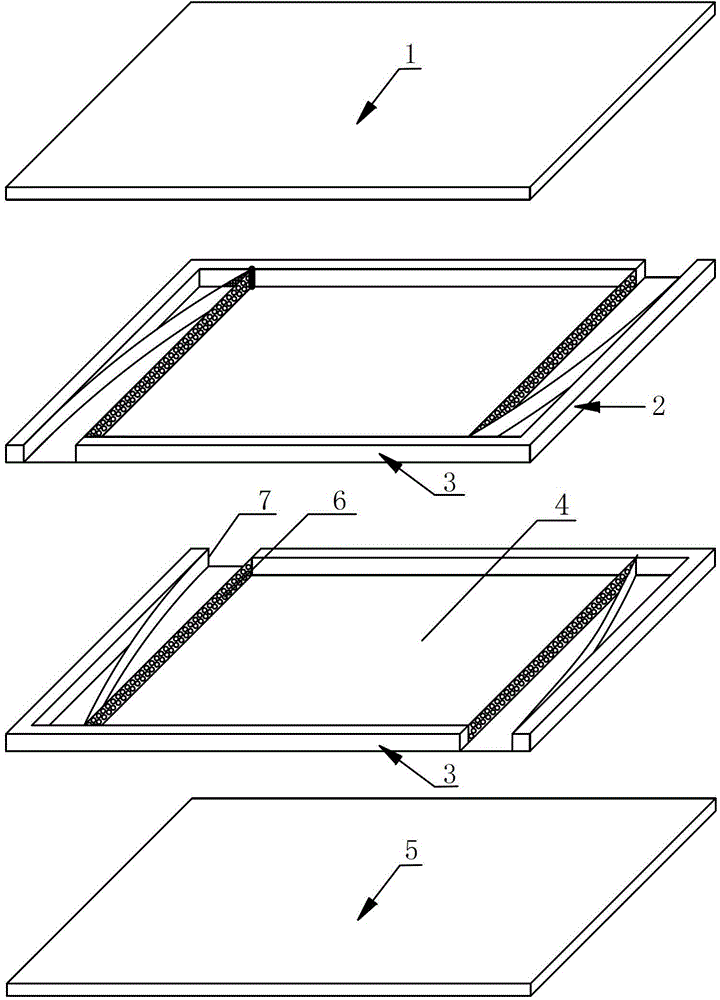

[0041] See attached figure 1 , 2 , 3, a flat full-heat heat exchange core body for a fresh air ventilator, including a top plate 1, a bottom plate 5, and a heat exchange unit 3, and the heat exchange unit 3 is composed of a heat exchange film 4, a support frame 2, a rectifying plate 6, The deflector 7 is composed of the supporting frame 2 in a rectangular shape, the heat exchange membrane 4 is fixedly connected with the supporting frame 2 to form the bottom surface of the supporting frame 2, and an opening is provided at each diagonal position of the supporting frame 2 8. The openings 8 are respectively arranged on two parallel sides of the supporting frame 2, one of which is an air inlet, and the other opening is an air outlet;

[0042] Two rectifying plates 6 are arranged between the air inlet and the air outlet, the rectifying plates 6 are perpendicular to the heat exchange membrane 4, and the two ends are respectively parallel to the two sides of the supporting frame 2 wh...

Embodiment 2

[0052] See attached Figure 4 , in this embodiment, the rest of the structure is the same as in Embodiment 1, except that the surface of the rectifying plate is provided with 5 strip-shaped holes, and the strip-shaped holes are evenly arranged in the height direction of the rectifying plate, and the length of the strip-shaped holes is arranged on the surface of the rectifying plate. The direction is provided with a bar-shaped baffle perpendicular to the surface of the rectifying plate and whose number matches the bar-shaped hole. The height of the bar-shaped hole is 5mm, the width of the bar-shaped baffle is 5mm, and the length of the bar-shaped hole and the bar-shaped baffle same.

Embodiment 3

[0054] See attached Figure 4 , in this embodiment, the rest of the structure is the same as in Embodiment 1, except that the surface of the rectifying plate is provided with 8 square holes, the holes of the square holes are directed in the same direction, and are evenly arranged along the length direction of the rectifying plate. There are arc-shaped baffles whose number matches the square holes. The width of the square holes is 25mm, and the height is basically consistent with the height of the heat exchange unit. The arc-shaped baffles are arranged tangentially to the sides of the square holes. The arc diameter is 20mm and the arc center angle is 90°.

[0055] When assembling the present invention, firstly prepare the composite heat exchange film, and then cut it into several sheets according to the length and width of the flat total heat exchange core body for the fresh air ventilator, such as figure 2 As shown, then the support frame, rectifying plate, and deflector are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com