Method for preparing pollution preventing self-cleaning polyvinylidene fluoride (PVDF) film and product thereof

A polyvinylidene fluoride film and self-cleaning technology, which is applied in the field of preparation of antifouling self-cleaning polyvinylidene fluoride film, can solve the problems of low light transmission performance of PVDF film, easy aggregation of nanoparticles, etc., and achieve good super hydrophobicity and anti-corrosion Pollution self-cleaning performance, improvement of grafting performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

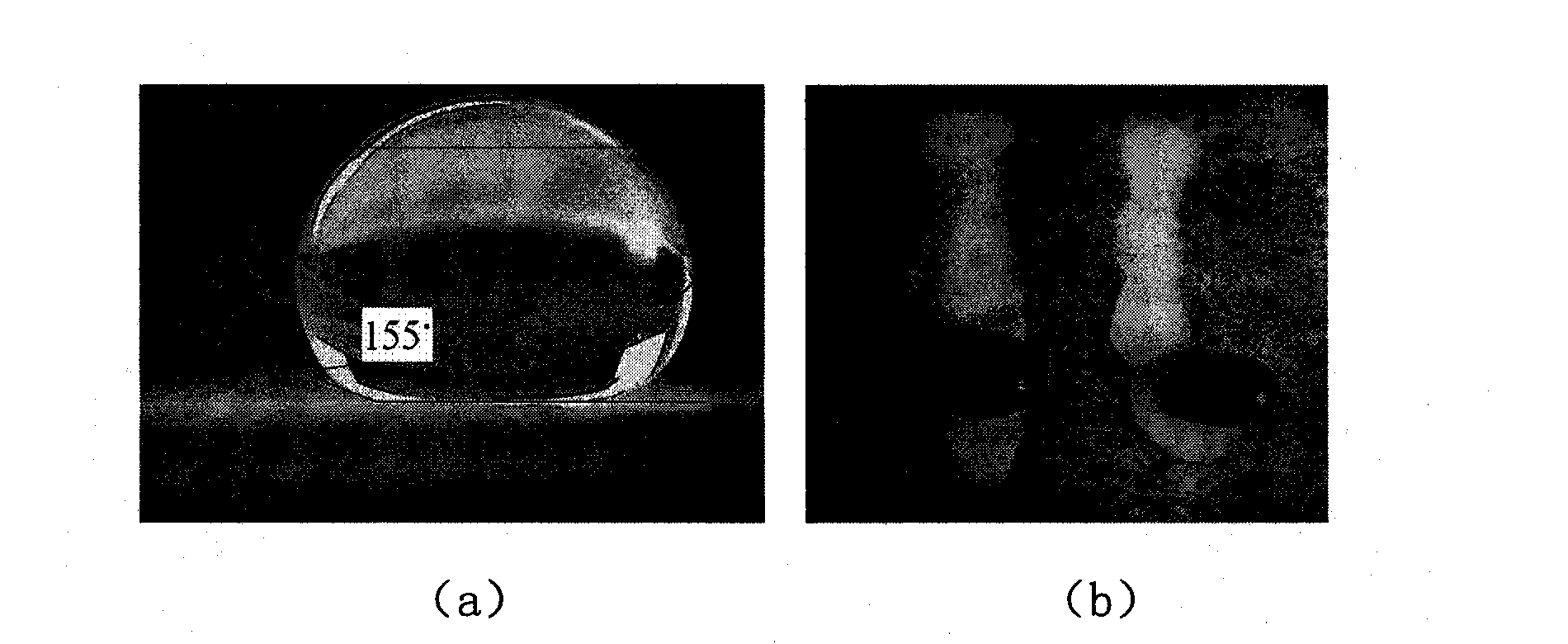

[0023] The anti-fouling self-cleaning (or super-hydrophobic) PVDF membrane preparation method (referred to as preparation method) designed by the present invention includes the following processes:

[0024] 1. Preparation of PVDF film: Dissolve PVDF powder in a solvent, prepare a PVDF solution with a mass fraction of 5-10%, stir at a constant temperature of 50-70°C for 1-2h, stand for defoaming for 30min, and coat the film at 90°C. The PVDF membrane is obtained by drying at -180°C; the solvent is acetone, dimethylformamide or dimethylacetamide;

[0025] 2. Alkaline treatment of PVDF membrane: Alkaline treatment of PVDF membrane includes two processes: alkali-aqueous solution treatment and alkali-alcohol solution treatment:

[0026] The alkali-aqueous solution treatment process is as follows: the PVDF membrane is immersed in an alkali-aqueous solution with a mass concentration of 20-40%, treated at 60-80 ° C for 2-3 hours, then taken out for washing and drying, that is, the hyd...

Embodiment 1

[0034] 1. Preparation of PVDF film: Dissolve PVDF powder in dimethylformamide solution, prepare a PVDF solution with a mass fraction of 5%, stir at a constant temperature of 60°C for 2h, let it stand for defoaming for 30min, coat the film, and dry it at 90°C. A PVDF membrane with a micron structure is produced.

[0035] 2. Alkaline treatment of PVDF membrane: immerse the PVDF membrane in NaOH-water solution with a mass concentration of 35%, treat it at 60°C for 3 hours, then take out the PVDF membrane, wash it with water, and dry it.

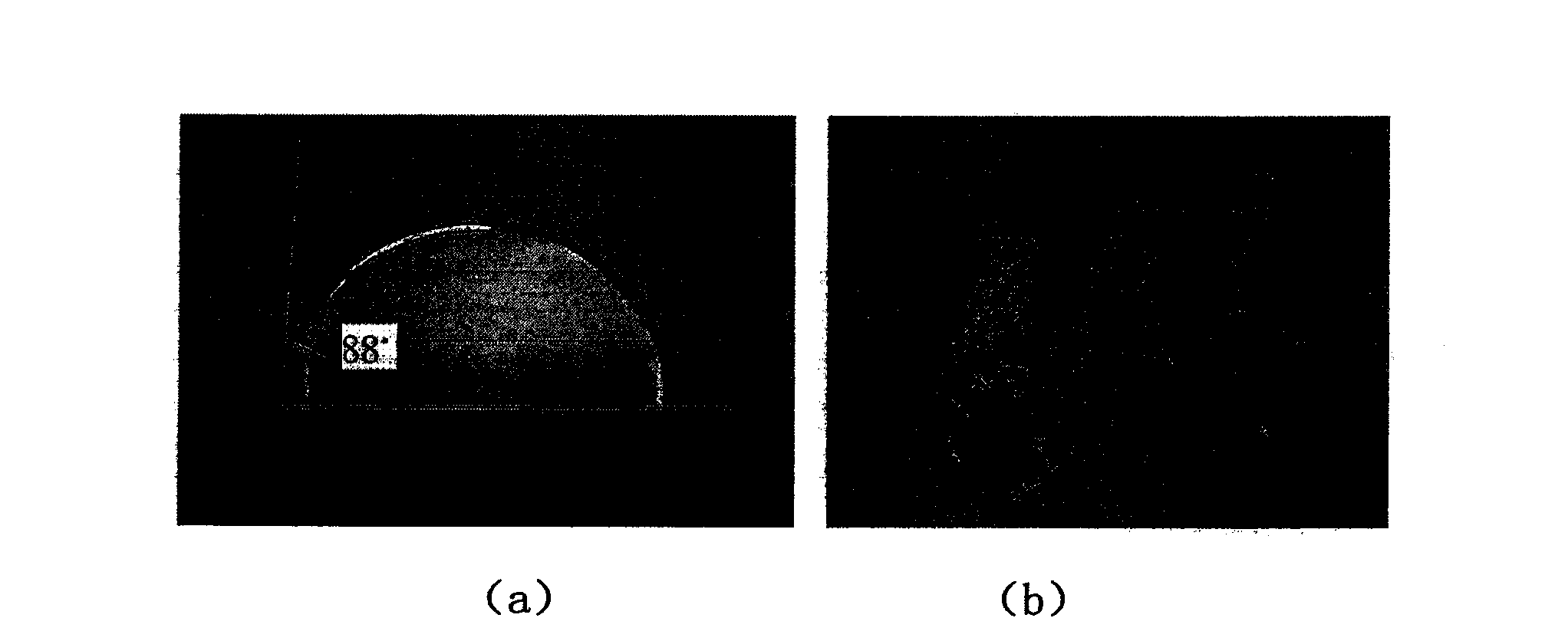

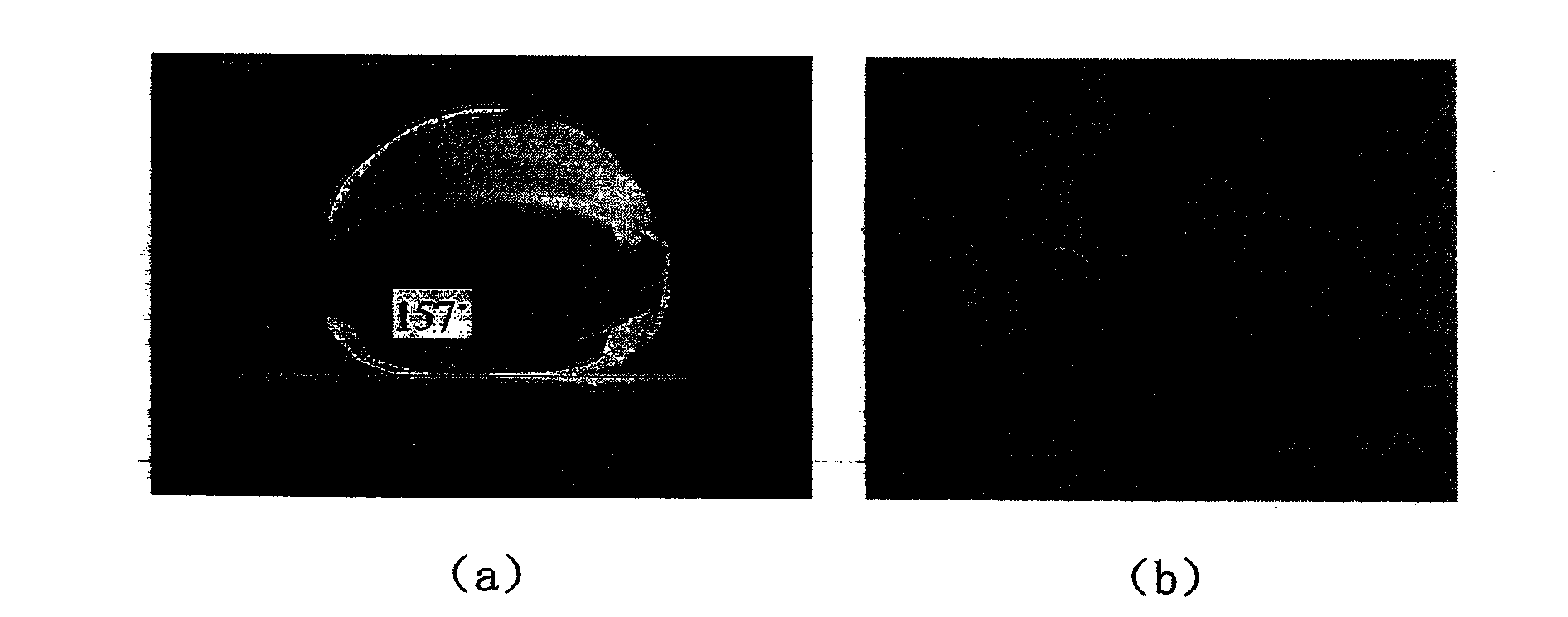

[0036] 3. PVDF membrane surface modification: prepare a toluene solution containing 8% methyltrichlorosilane and 12% dimethyldichlorosilane by volume, put it in an airtight container with a relative humidity of 80% for use, and then put the second Step 2: Immerse the PVDF membrane treated with NaOH solution in the toluene solution in the airtight container, carry out surface treatment for 30min, take out the PVDF membrane after treatment, and us...

Embodiment 2

[0039] 1. Preparation of PVDF membrane: Dissolve PVDF powder in dimethylacetamide solution, prepare a PVDF solution with a mass fraction of 5%, stir at a constant temperature of 70°C for 1.5h, stand for defoaming for 30min, coat the film, and dry at 120°C , to produce a PVDF membrane with a micron structure.

[0040] 2. Alkaline treatment of PVDF membrane: immerse the PVDF membrane in KOH-ethanol solution with a mass concentration of 5%, and treat it at 40°C for 3 minutes, then take out the PVDF membrane, wash it with water, and dry it; then immerse the PVDF membrane in a mass concentration of 4% KMnO 4 / 30% KOH-water solution, react at room temperature for 10 minutes, take out, wash with water, and dry.

[0041] 3. PVDF membrane surface modification: prepare a toluene solution containing 7.4% methyltrichlorosilane and 12.6% dimethyldichlorosilane by volume fraction, put it in an airtight container with a relative humidity of 80% for use, and then put the first Step 2: Immers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com