Method for preparing biodegradable polyester and original montmorillonoid soil nano composite material

A technology of biodegradable polyester and nanocomposite materials, applied in the field of montmorillonite nanocomposite materials, can solve the problems of time and energy consumption, increased steps, fewer reports, etc., and achieve improved barrier properties, use temperature, and gas barrier properties Good, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of biodegradable polyester montmorillonite raw soil nano-composite material, the method comprises the following steps:

[0023] (1) Montmorillonite (cation exchange capacity 85mequiv·100g -1 ) was dispersed in deionized water, stirred at 70° C. for 4 hours to obtain a suspension of montmorillonite with a concentration equal to 2 wt %;

[0024] (2) dissolving polycaprolactone (PCL) in N, N-dimethylformamide to make a polycaprolactone solution with a concentration equal to 5wt%;

[0025] (3) Mix the above PCL solution and montmorillonite suspension according to the mass ratio (100:0; 97.5:2.5; 95:5; 91:9; 82:18; 78:22) and mix them evenly at a temperature lower than 120°C The polycaprolactone montmorillonite native soil nanocomposite was prepared by evaporating the solvent, wherein the montmorillonite content was 0wt%, 1wt%, 2wt%, 4wt%, 8wt%, and 10wt%.

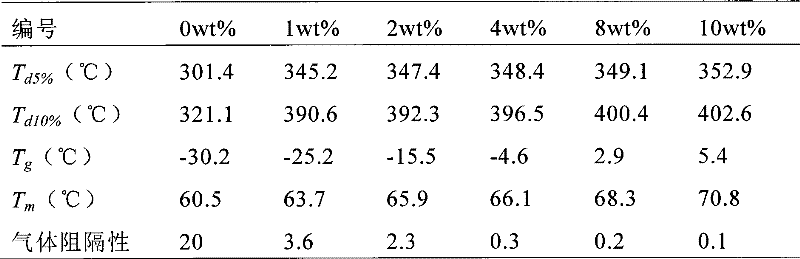

[0026] Compared with the montmorillonite content of 0wt%, the polycaprolactone montmorillonite ...

Embodiment 2

[0031] A preparation method of biodegradable polyester montmorillonite raw soil nano-composite material, the method comprises the following steps:

[0032] (1) Montmorillonite (cation exchange capacity 85mequiv·100g -1 ) was dispersed in deionized water, stirred at 70°C for 4 hours to obtain a concentration equal to 4wt%;

[0033] (2) dissolving polylactic acid (PLA) in N,N-dimethylacetamide to make a polylactic acid solution with a concentration equal to 10wt%;

[0034] (3) Mix the above PLA solution and montmorillonite suspension according to the mass ratio (100:0; 97.5:2.5; 95:5; 91:9; 82:18; 78:22) and mix them evenly at a temperature lower than 120°C The polylactic acid montmorillonite original soil nanocomposite was prepared by evaporating the solvent, wherein the montmorillonite content was 0wt%, 1wt%, 2wt%, 4wt%, 8wt%, and 10wt%.

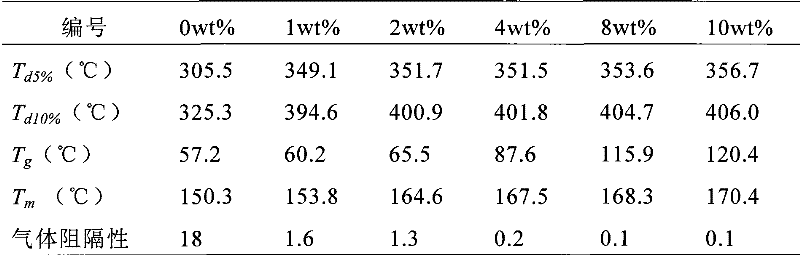

[0035] Compared with the montmorillonite content of 0wt%, the heat resistance, barrier and service temperature of polylactic acid montmor...

Embodiment 3

[0040] A preparation method of biodegradable polyester montmorillonite raw soil nano-composite material, the method comprises the following steps:

[0041] (1) The montmorillonite original soil (cation exchange capacity greater than 45mequiv·100g -1 ) was dispersed in deionized water, stirred at 50° C. for 6 hours to obtain a montmorillonite suspension with a concentration equal to 5 wt %;

[0042] (2) dissolving technical-grade polycaprolactone (PCL) in technical-grade N,N-dimethylformamide to make a polycaprolactone solution with a concentration equal to 20wt%;

[0043] (3) Mix the above PCL solution and montmorillonite suspension according to the mass ratio (100:0; 96:4; 92.5:7.5; 85.7:14.3; 74:26; 69:31), and volatilize at a temperature of 100°C The polycaprolactone montmorillonite native soil nanocomposite material is prepared from the solvent, wherein the montmorillonite content is 0wt%, 1wt%, 2wt%, 4wt%, 8wt%, and 10wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com