Splittable conjugate fiber

A composite fiber, split-type technology, applied in fiber processing, filament/thread forming, conjugated synthetic polymer man-made filaments, etc. Good color, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

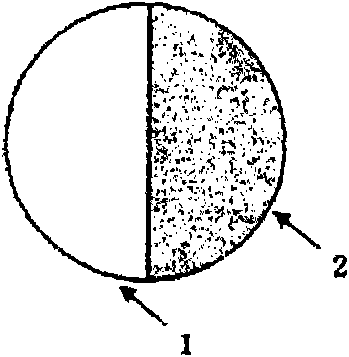

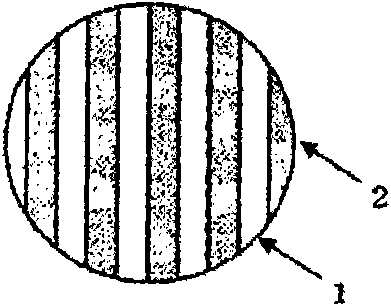

[0076] Nylon MXD6 having a relative viscosity of 2.7 and nylon 6 having a relative viscosity of 3.0 were mixed at a weight ratio of 50:50 to obtain a polyamide resin composition as component A. In addition, polyethylene terephthalate having an intrinsic viscosity of 0.61 was used as the B component.

[0077] According to the ratio of A component: B component volume ratio is 1: 2, under the condition of spinning temperature 295 ℃, spinning speed 1500m / min, carry out melt composite spinning in the mode that A component constitutes the radial part, obtain almost the same as Figure 4 Undrawn filaments of the same cross-section. At this time, component A is supplied to a metering pump through a static mixer after melting. Then, the obtained undrawn yarn was drawn under the conditions of a roller heater of 85°C, a plate heater of 150°C, and a drawing speed of 2.50 times to obtain a split-type conjugate fiber of 110dtex / 50f.

[0078]Then, using this drawn yarn, a tube knitting fab...

Embodiment 2、3

[0082] [Example 2, 3, Comparative Example 1, 2]

[0083] Except for changing the weight ratio of nylon MXD6 and nylon 6 which are polyamide components, fibers were produced by the method described in Example 1, and various evaluations were performed.

[0084] [Table 1]

[0085]

Embodiment 4

[0097] Except that the B component was made of polypropylene, and the treatment method was immersion in 98° C. hot water for 10 minutes, fibers were produced by the method described in Example 1, and various evaluations were performed. The results are shown in Table 2.

[0098] Due to the low adhesion between polyolefin and polyamide, it is easy to use hot water to cut fibers and shrink. Moreover, a product with soft touch and good bulkiness was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com