Sand-measuring ionization chamber

An ionization chamber and sand measurement technology, applied in the field of sand measurement ionization chamber, can solve the problems of low detection efficiency and strong absorption of low-energy γ-ray sources, and achieve the effect of small statistical error, good long-term signal stability, and reduction of natural discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

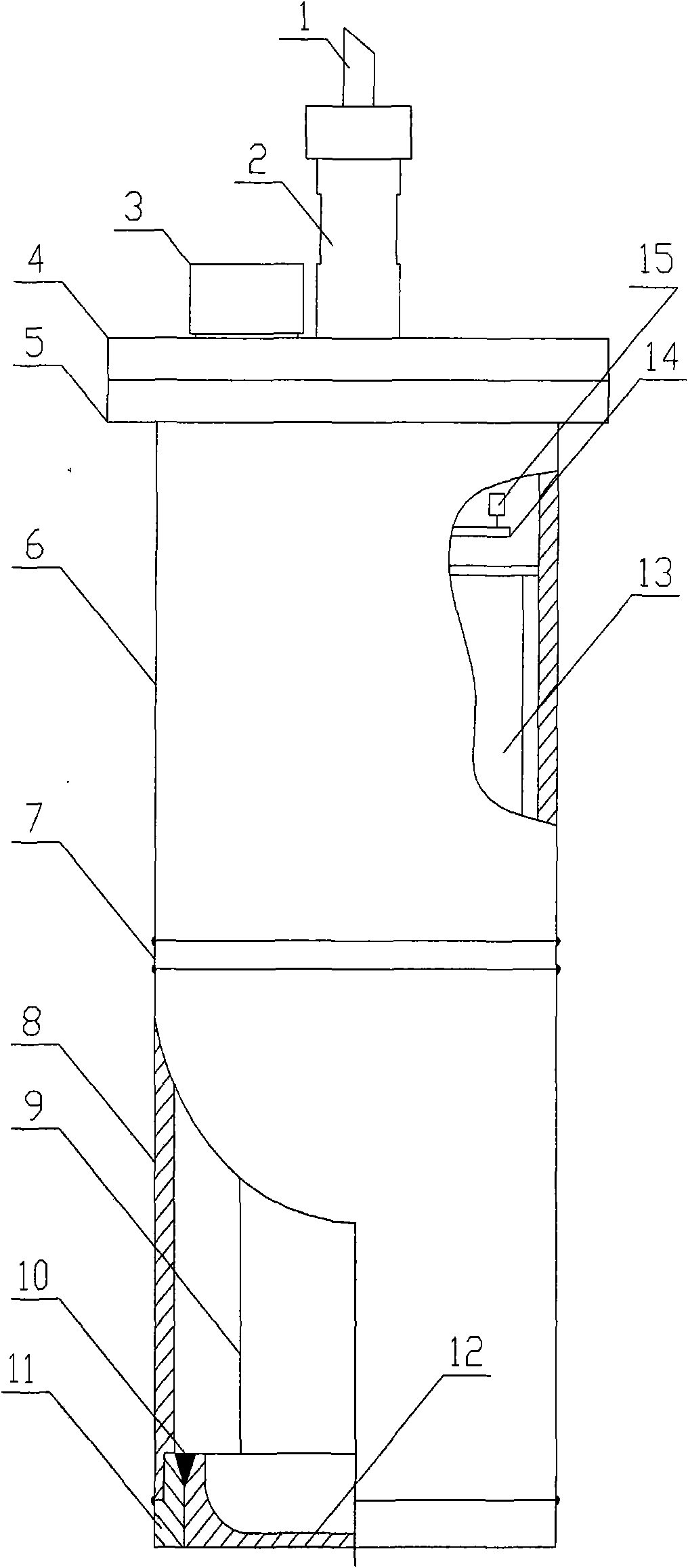

[0019] Depend on figure 1 It can be seen that the interior of the sand measuring ionization chamber is divided into two independent parts, the upper part is the upper end pipe 6, and the lower part is the lower end pipe 8; the upper end pipe 6 has a flange ring 5, and the flange ring 5 is connected with the end cover 4 Sealed connection, the end cover 4 is equipped with a pressure sensor 3; the upper end tube 6 and the lower end tube 8 are connected by a flange 7 and separated into two independent parts, and the upper end tube 6 is equipped with an amplifier board 14 and a high voltage power supply for a high voltage power supply frame 13, temperature sensor 15; the lower end tube 8 is equipped with an electrode cylinder 9 and filled with high-pressure inert gas, the top of the lower end tube 8 is equipped with a stainless steel window cap 11 and an aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com