Liquid coupling reverse-cutting transmission case

A technology of hydraulic coupling and transmission box, applied in transmission device, fluid transmission device, belt/chain/gear, etc., can solve the problems of shortened service life, black smoke from diesel engine, car stagnation, gear and bearing damage, etc. , to achieve the effect of stepless adjustment of output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

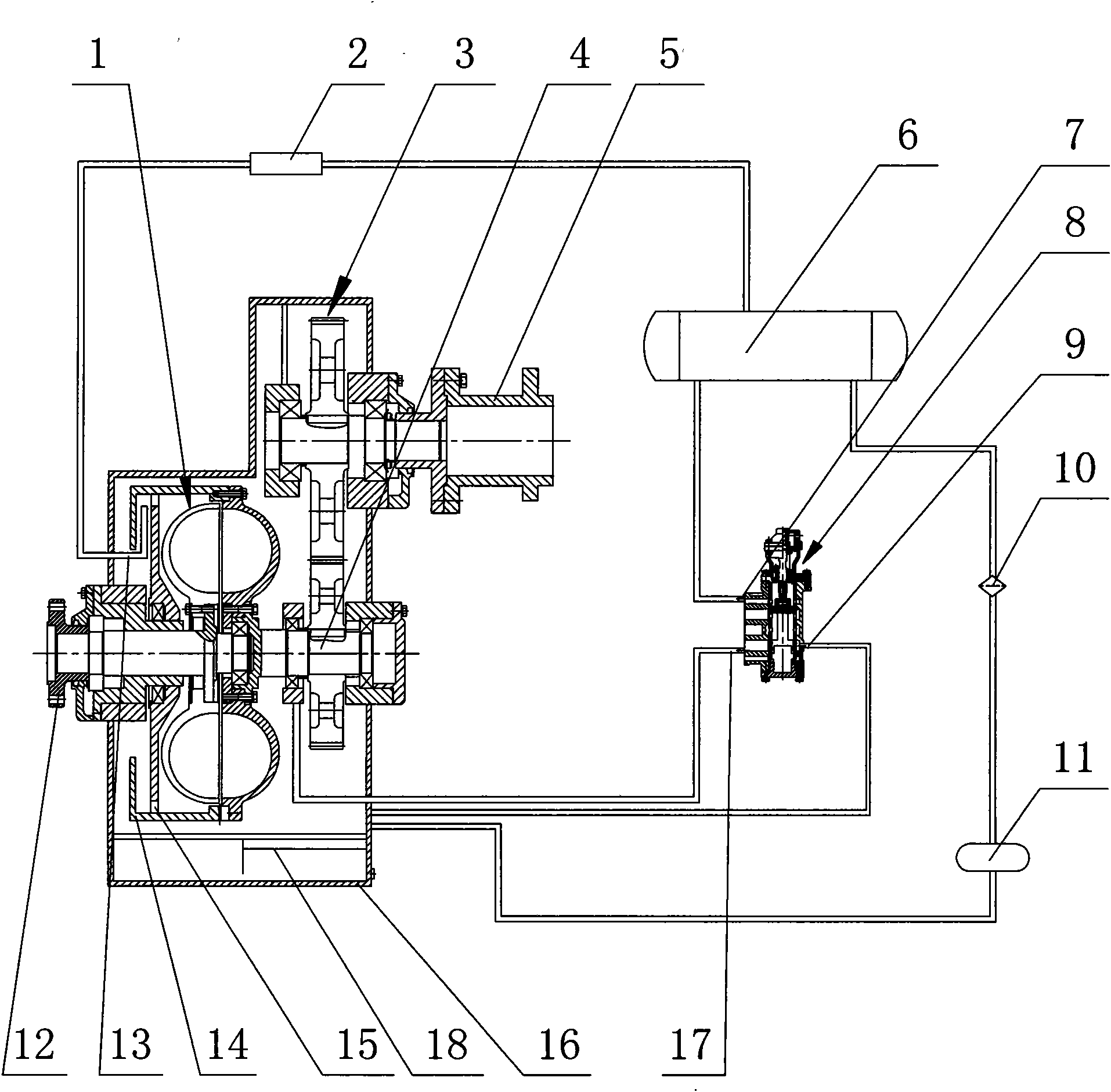

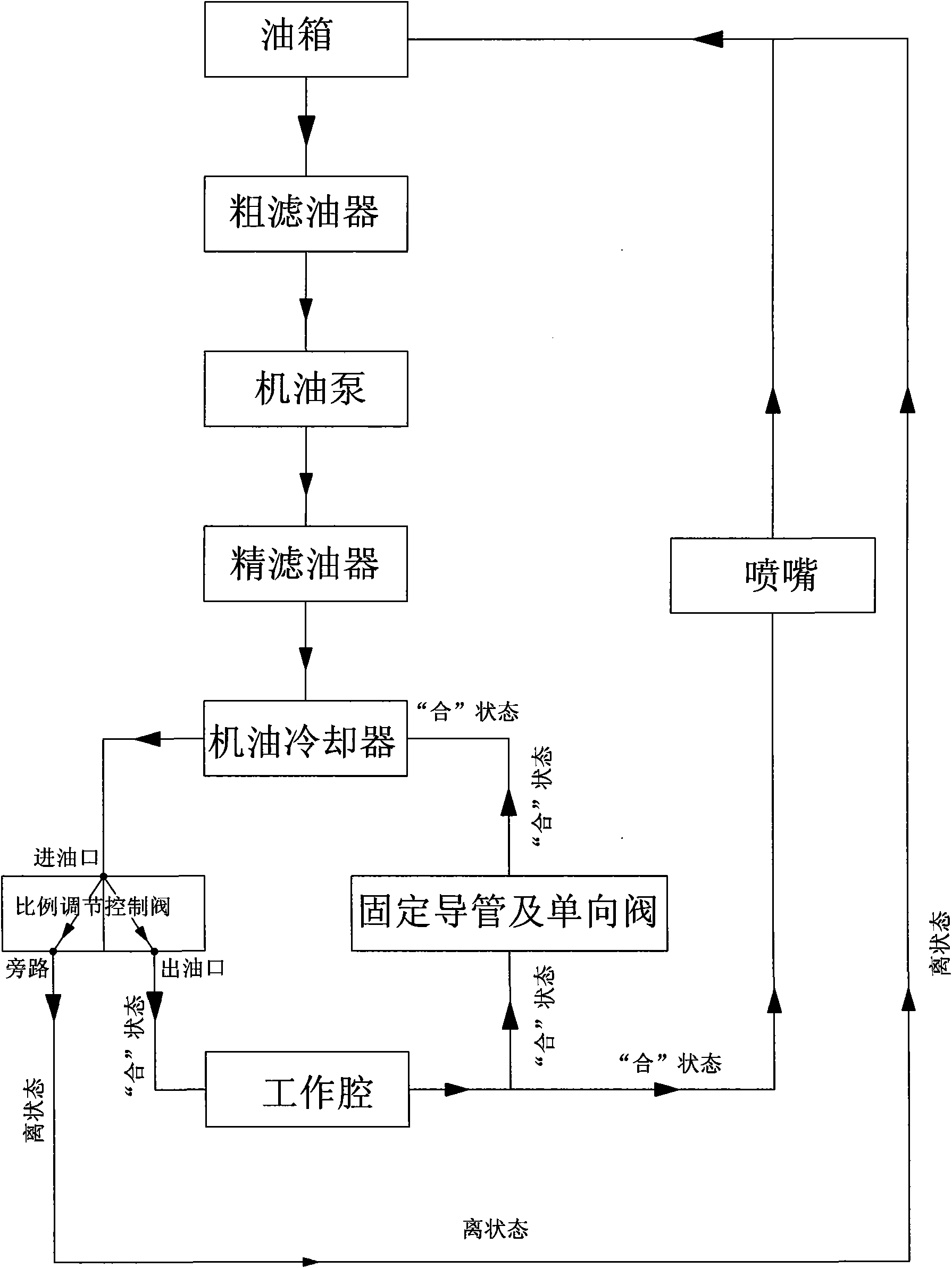

[0011] Such as figure 1 As shown, the present invention is a reverse transmission case of a fluid coupling, which includes a fluid coupling 1 , and a quick clutch mechanism is arranged between the working chamber of the fluid coupling 1 and the fuel tank 16 . The quick clutch mechanism is a quick oil discharge pipeline arranged between the working chamber of the fluid coupling 1 and the oil tank 16; the quick clutch mechanism includes an outer cover 14 fixedly connected with the driving wheel of the fluid coupling 1, and the outer cover 14 is connected with the hydraulic coupling The working chamber of 1 is connected through the oil hole 15. A fixed conduit 13 is installed in the outer cover 14. The opening direction of one end of the fixed conduit 13 is facing the oil direction of the high-speed rotating working oil in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com