Speed regulating device for fixed conduit nozzle valve-controlled hydraulic coupler

A technology of hydraulic coupling and speed control device, which is applied in the direction of transmission device, fluid transmission device, belt/chain/gear, etc. It can solve the problems of oil discharge valve stuck fault, poor workmanship, complex structure, etc., and achieve rapid discharge oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

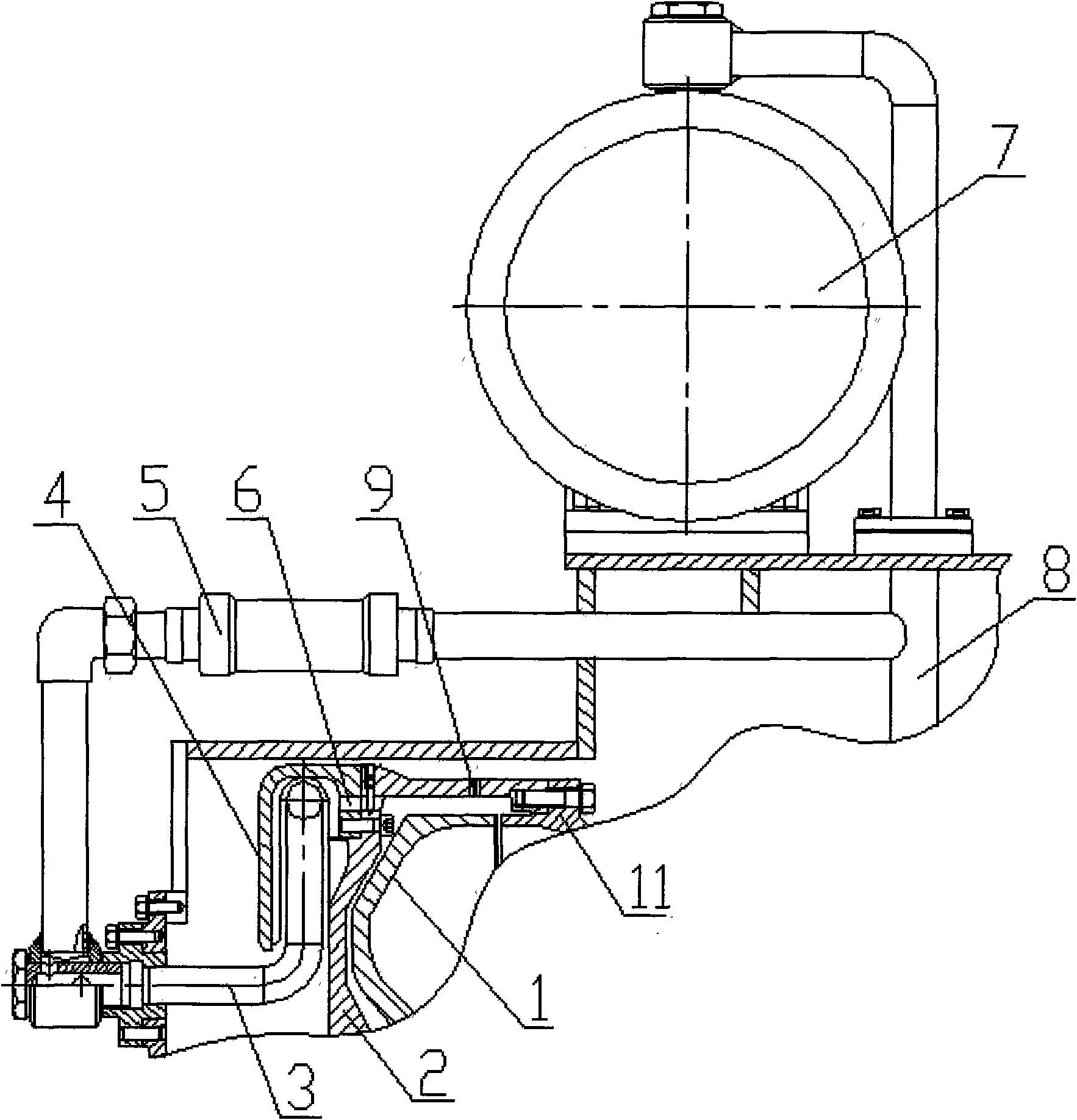

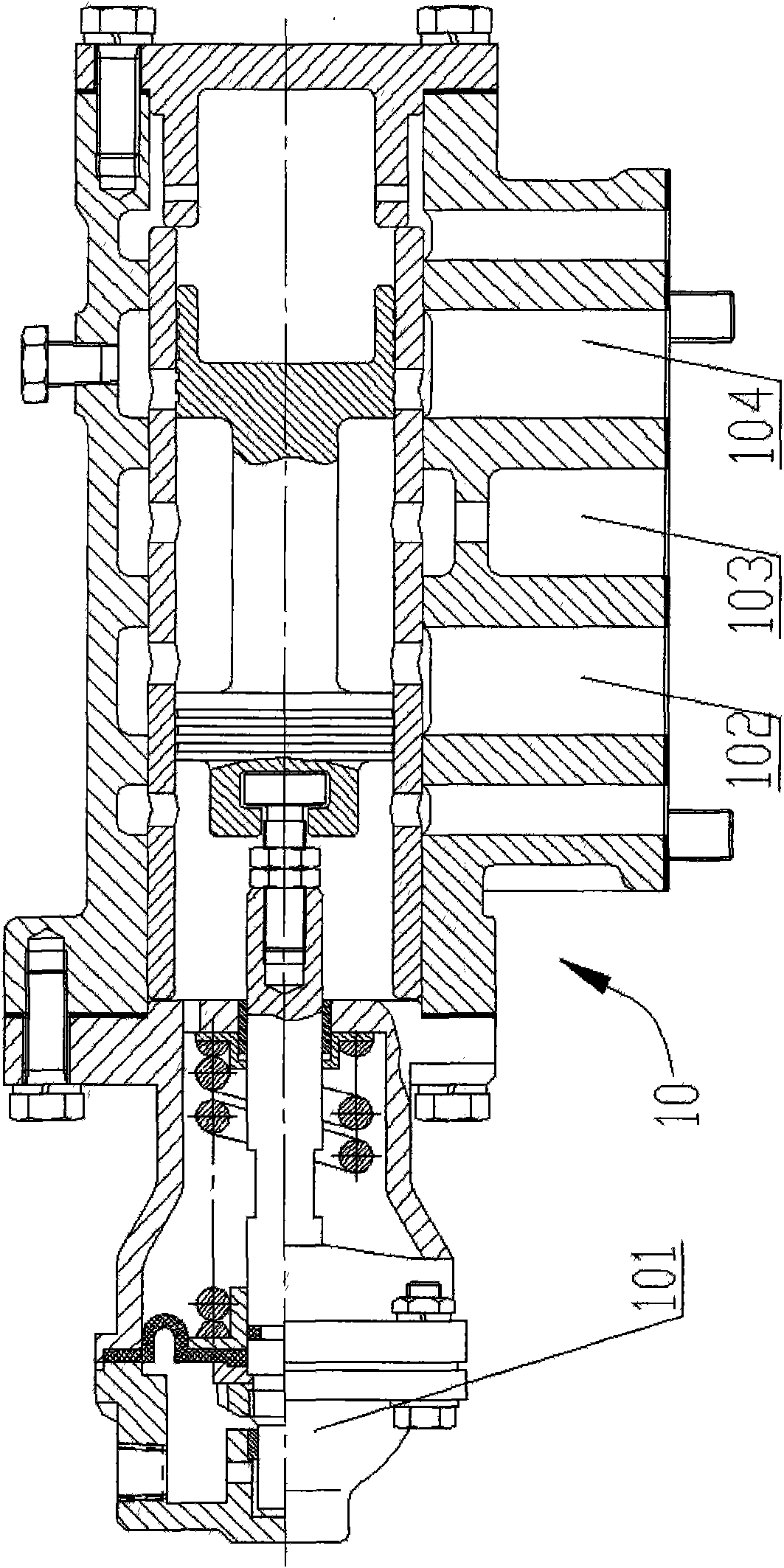

[0012] When the embodiment of the present invention is implemented, its designed main mechanism includes a turbine 1, a pump wheel cover 2, a fixed conduit 3, an outer cover 4, radial blades 41, a one-way valve 5, an oil hole 6, an oil cooler 7, and a main oil circuit 8 , nozzle 9, pneumatic proportional control valve 10 and pump wheel 11. The side wall of the pump wheel cover 2 is provided with a nozzle 9; the outer rigid connection of the pump wheel cover 2 is provided with an outer cover 4, and the inner side of the outer cover 4 is provided with radial blades 41, and the outer cover 4 is provided with a pump wheel 11 and a turbine. The working chamber formed by 1 is connected to the oil hole 6, and the outer cover 4 is provided with a fixed conduit 3, and the opening direction of the fixed conduit 3 faces the direction of the high-speed rotating cycle of the working oil in the outer cover 4, and the fixed conduit 3 is provided with a one-way valve. 5. A pneumatic proportio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com