Novel multi-gyration compressor

A rotary compressor, a new type of technology, applied in the direction of rotary piston machinery, mechanical equipment, machines/engines, etc., can solve the problems of high noise, small cooling capacity, low efficiency, etc., and achieve high gas transmission coefficient, easy processing, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

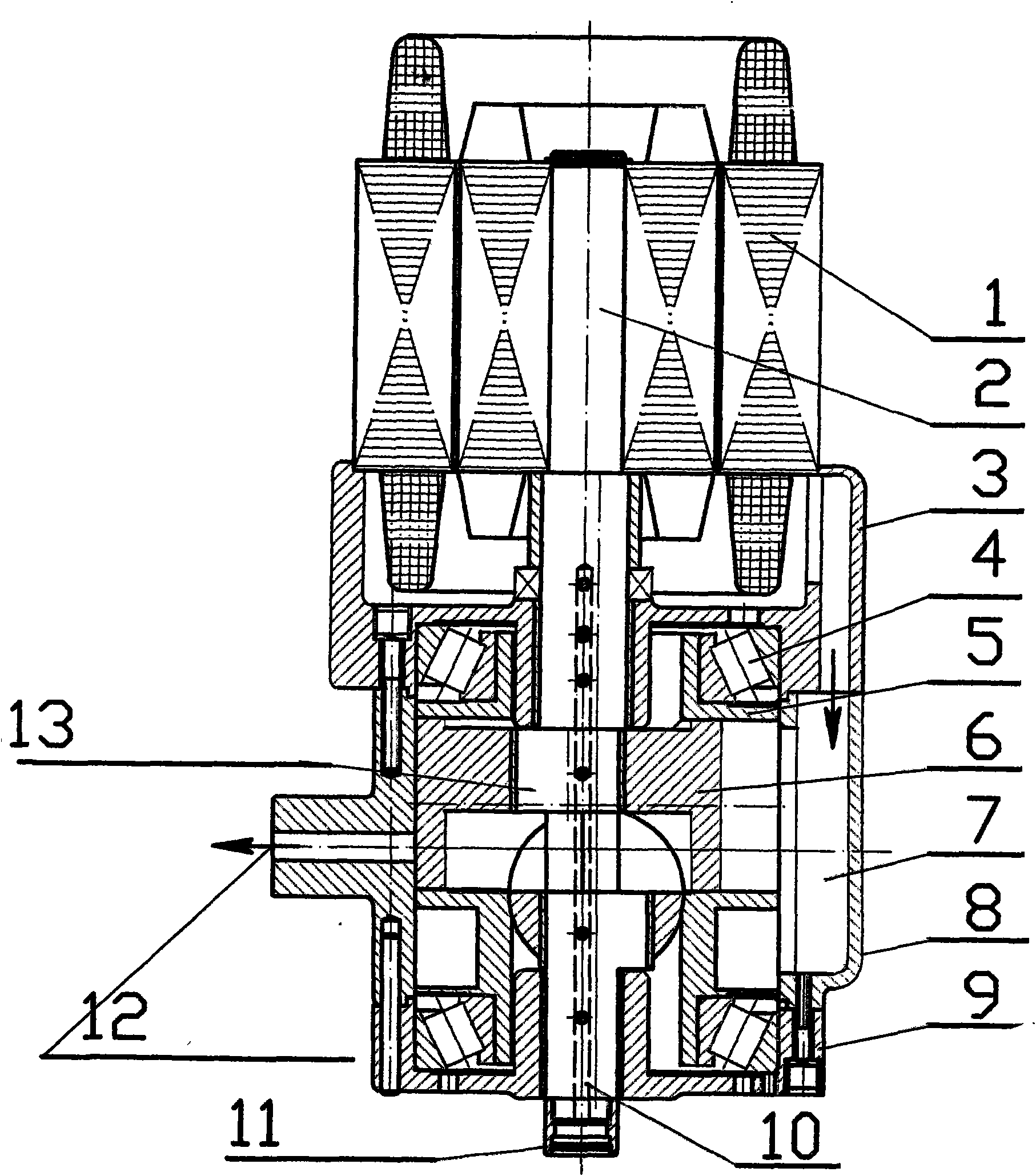

[0025] see figure 1 There is an electric motor 1, the rotor of the electric motor 1 is fixedly connected with one end of the crankshaft 2, the main shaft diameter of the crankshaft 2 is installed in the bearing holes of the upper cover seat 3 and the lower cover 9 respectively, and the eccentric journal 13 of the crankshaft 2 is equipped with a piston 6; Put it into the piston hole of the rotary cylinder 5; the crankshaft 2 passes through the central hole of the rotary cylinder 5.

[0026] Present embodiment crankshaft 2 is drilled with eccentric thin hole 10.

[0027] In this embodiment, an air intake channel is provided between the shell 8 and the upper cover seat 3; the shell 8 is provided with an air intake chamber 7.

[0028] In this embodiment, the casing 8 is fully enclosed, and a protruding exhaust port 12 is provided on its side.

[0029] In this embodiment, two ends of the rotary cylinder 5 are provided with bearings 4 .

[0030] In this embodiment, the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com