A supercavitating torpedo

A supercavitation and torpedo technology, which is used in motor-driven engines, special-purpose ships, ship construction, etc., can solve the problem of inability to realize automatic switching of two rudder shafts synchronously rotating in the same direction, high assembly tightness requirements, and poor gas controllability. and other problems, to achieve the effect of light weight, small volume and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

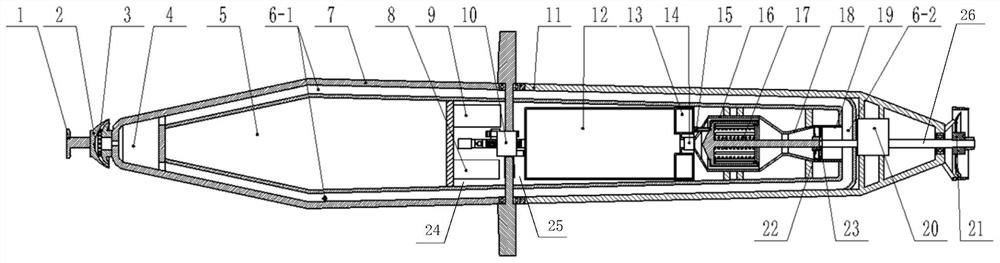

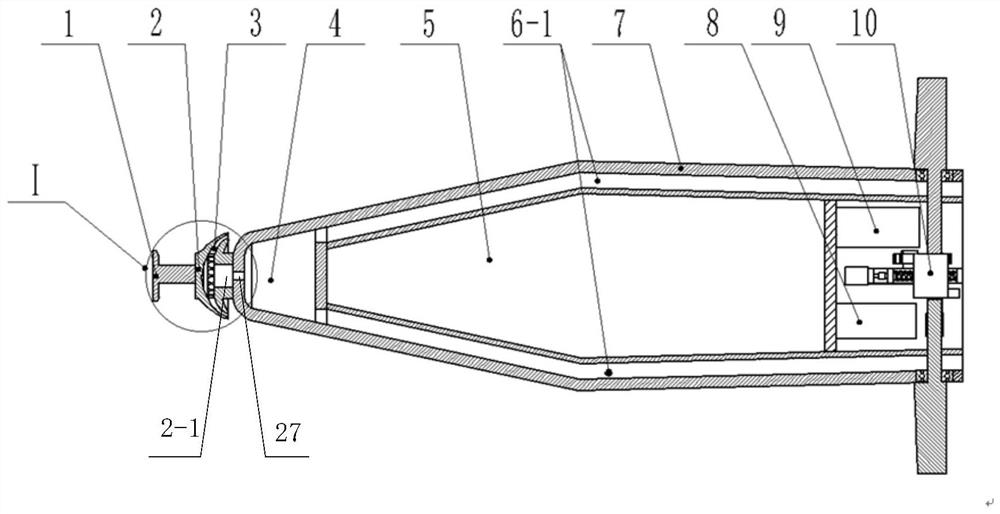

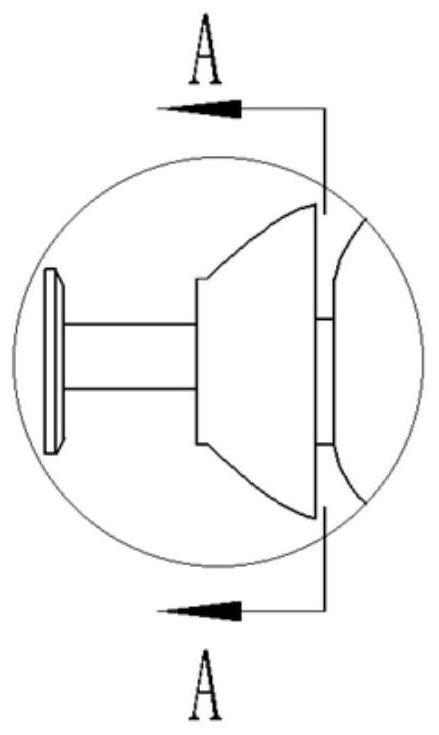

[0040] see figure 1 , the cabin body includes the front cabin section 7 and the rear cabin section 11, the front and rear cabin sections are fixedly connected to form the whole cabin body, a steering gear device 10 is arranged between the front cabin section 7 and the rear cabin section 11, and the rear end of the front cabin section 7 is installed There is a rudder, and the front end of the head cone section of the front cabin section 7 is sleeved with a ventilation bowl 2, and a cavitator 1 is installed at the front end of the ventilation bowl 2. In the cabin, exhaust gas accumulation cabin 4, air passage front section 6-1, ammunition cabin 5, control system 8, battery system 9, steering gear device 10, and compressed gas storage tank are sequentially arranged in the cabin along the axial direction from the front cabin section 7 to the rear cabin section 11 12. Annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com