Low welding crack sensitivity steel with tensile strength at 700MPa level and production method thereof

A technology with low welding crack and tensile strength, used in temperature control, manufacturing converters, etc., can solve problems such as low strength, and achieve the effects of excellent welding performance, low welding crack sensitivity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

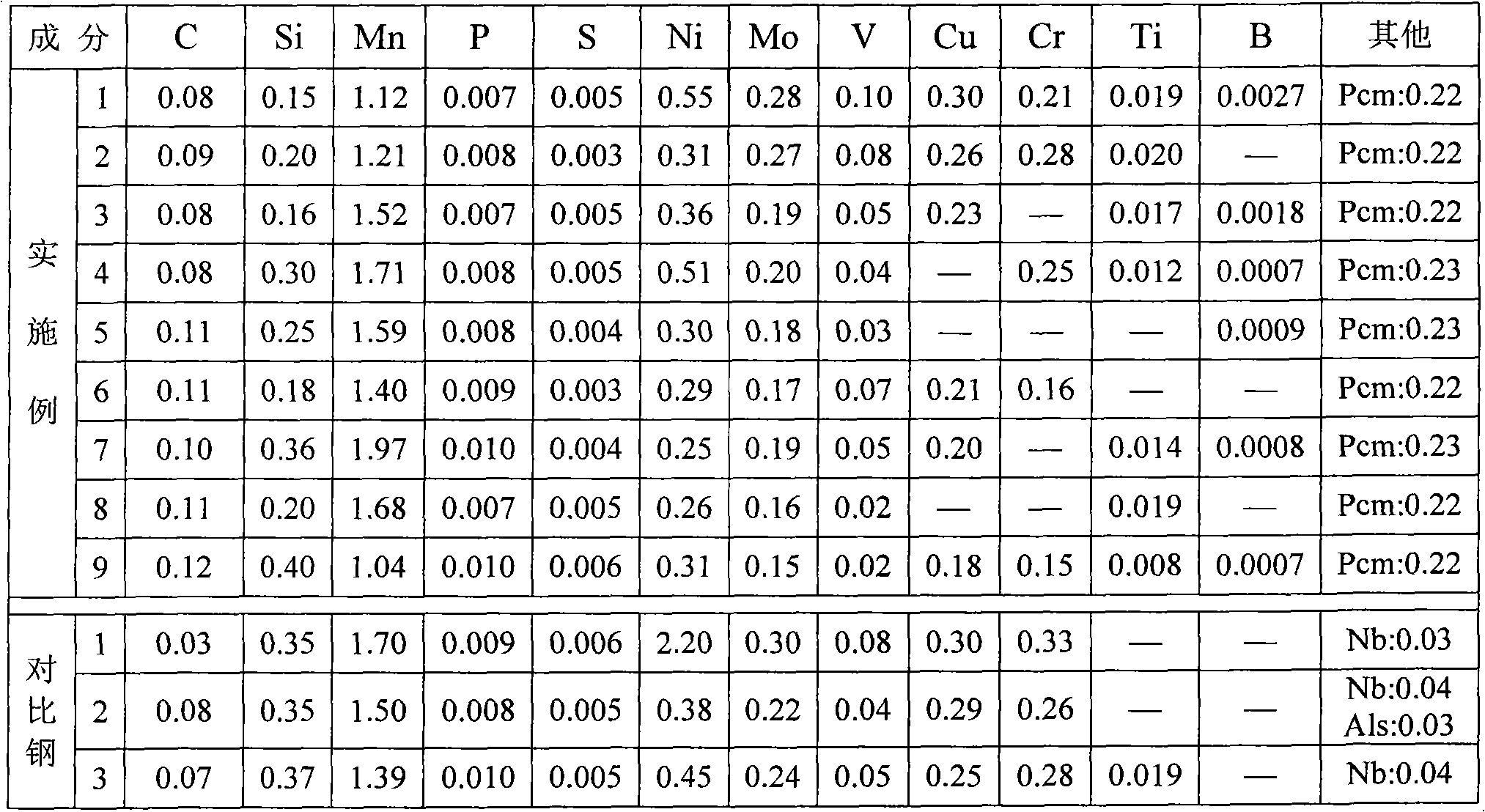

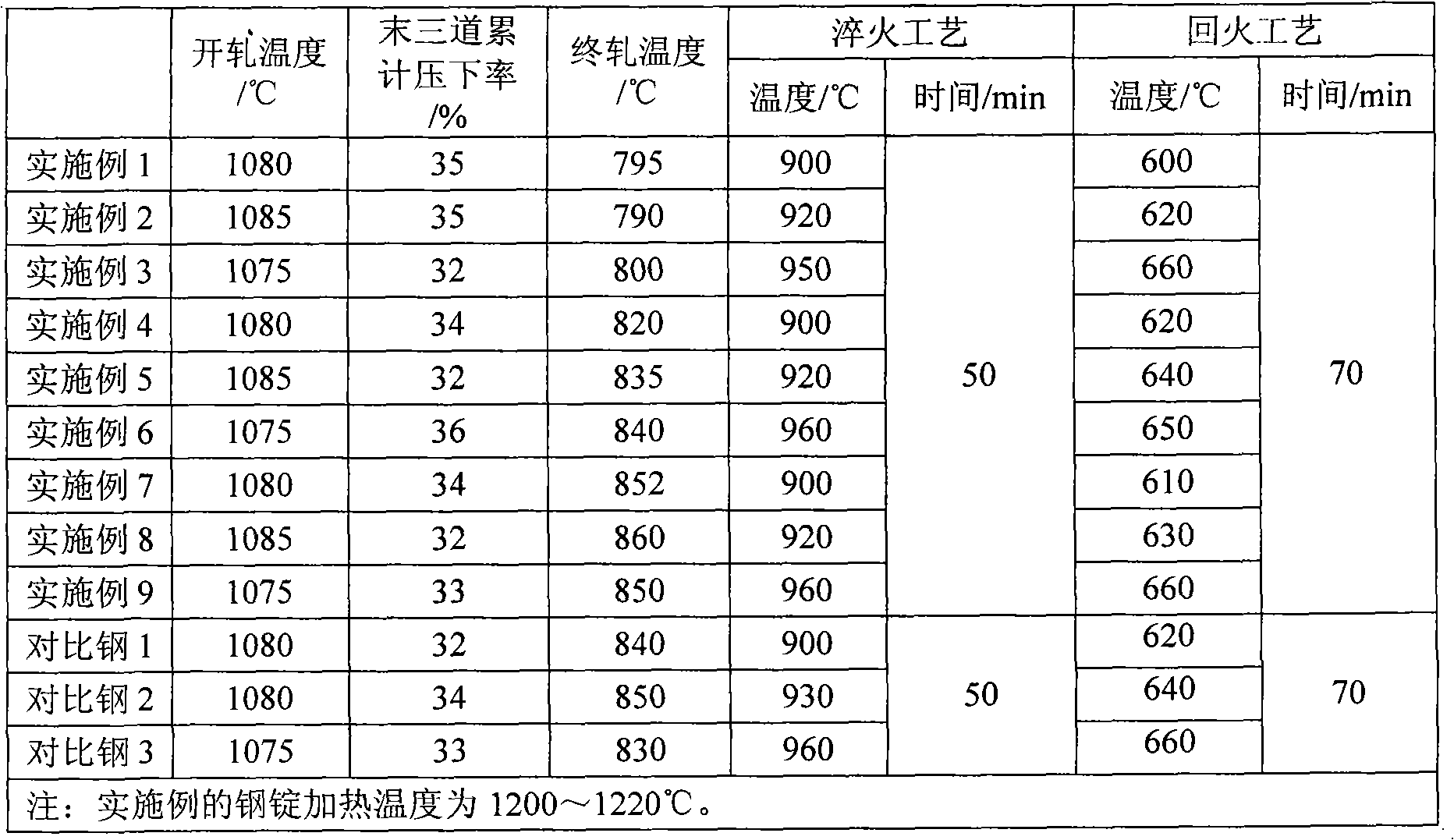

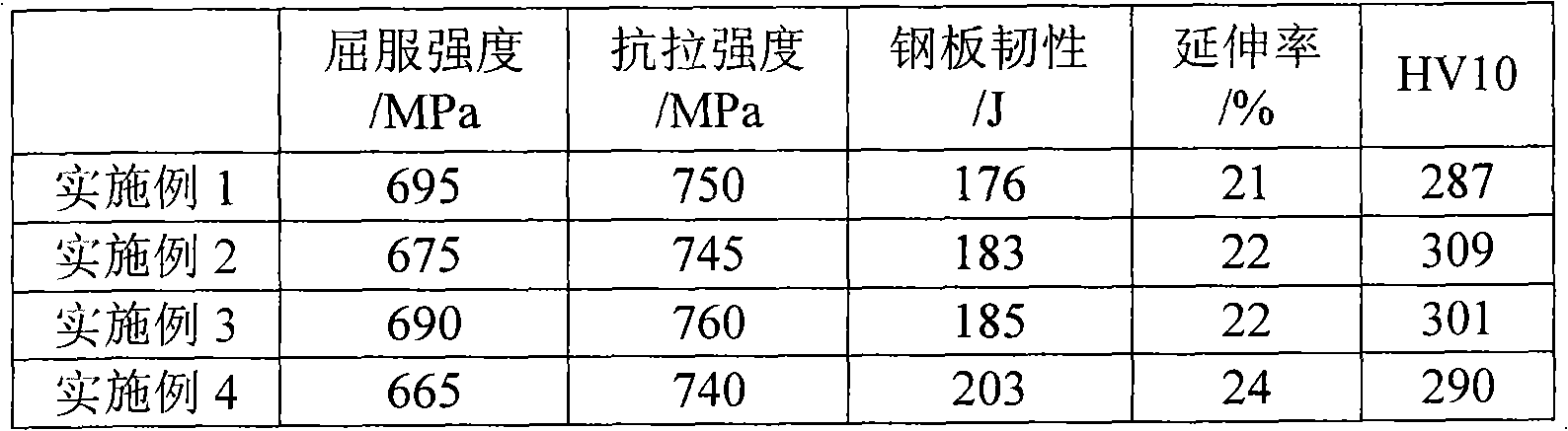

[0037] Embodiment: Carry out 9 embodiments (specification 16mm) by steel chemical composition of the present invention and production technology requirement, and with the steel grade of related technology in the background technology, as Sumitomo Metal (comparison steel 1), Anshan Iron and Steel (comparison steel 2) , Wuyang Iron and Steel Company (comparison steel 3) to conduct a comparative test. The chemical composition of the steels of the examples and the comparison is shown in Table 1, the rolling and heat treatment processes are shown in Table 2, and the mechanical properties are shown in Table 3.

[0038] Table 1 embodiment and comparative steel chemical composition (wt, %)

[0039]

[0040] Table 2 Example and comparative steel production process

[0041]

[0042] Table 3 embodiment and comparative steel properties

[0043]

[0044]

[0045] Best Example 1: The weight percentage of the chemical composition of the steel is C: 0.08, Si: 0.25-0.30, Mn: 1.70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com