Expansion-type halogen-free flame retardant and flame retardant master batch using same

A flame retardant masterbatch, expansion type technology, applied in the field of expansion type halogen-free flame retardant, flame retardant masterbatch, can solve the problems of non-woven fabrics easy to burn, high calorific value, easy to cause fire, etc., to reduce pollution , Make up for the effect of heavy smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

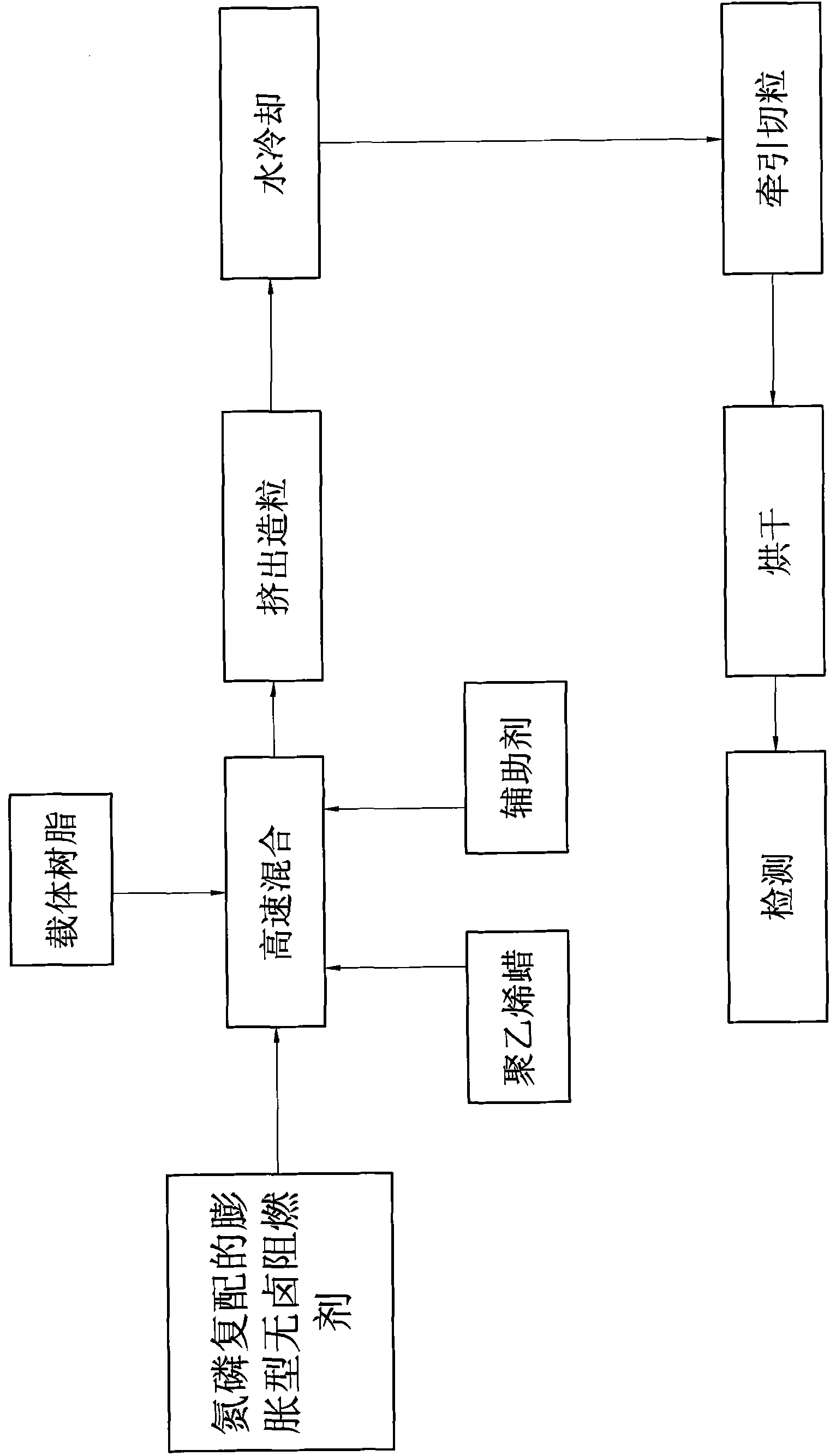

Method used

Image

Examples

Embodiment 1

[0017] An expansion type halogen-free flame retardant, the weight percentage of each component is: 30% of phosphide, 20% of diaminodiphenylmethane, 50% of amine expansion agent.

[0018] The flame retardant masterbatch adopting the above-mentioned expansion type halogen-free flame retardant, the weight percentage of each component is: expansion type halogen-free flame retardant 50%, polyethylene wax 3%, carrier resin 45%, auxiliary agent 2%.

Embodiment 2

[0020] An intumescent non-halogen flame retardant, the weight percentage of each component is: phosphide 35%, diaminodiphenylmethane 20%, amine expansion agent 45%.

[0021] The flame retardant masterbatch using the above-mentioned intumescent non-halogen flame retardant, the weight percentage of each component is: intumescent non-halogen flame retardant 65%, polyethylene wax 3%, carrier resin 30%, auxiliary agent 2%.

Embodiment 3

[0023] An expansion type halogen-free flame retardant, the weight percentage of each component is: 25% of phosphide, 23% of diaminodiphenylmethane, and 52% of amine expansion agent.

[0024] The flame retardant masterbatch using the above-mentioned intumescent halogen-free flame retardant, the weight percentage of each component is: intumescent halogen-free flame retardant 55%, polyethylene wax 2%, carrier resin 42%, auxiliary agent 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com