Vacuum Filtration Combined Electric Dewatering Sludge Treatment System

A sludge treatment and electric dehydration technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of low operation efficiency, poor dehydration effect, high treatment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

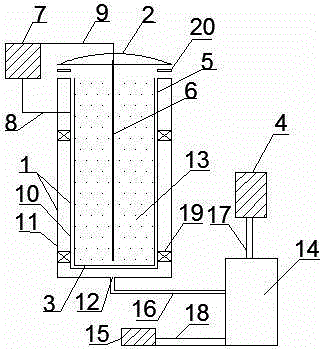

[0026] Below in conjunction with embodiment and attached figure 1 or attached figure 2 The specific implementation of the product technology of the vacuum filtration combined with electric dewatering sludge treatment system disclosed in the present invention is further described.

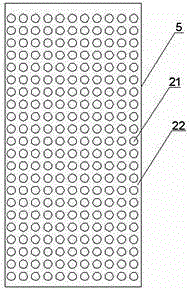

[0027]According to the technical solution of the present invention, the vacuum filtration combined electric dewatering sludge treatment system includes a double-layer vacuum dehydration barrel 1, a barrel cover 2, a filter bag 3, a vacuum pump 4, a cathode discharge electrode 5, an anode discharge electrode 6, a power supply 7, and a cable 8. Cable 2 9. The double-layer vacuum dehydration barrel 1 is a double-layer barrel structure formed by the combination of the inner barrel body 10 and the outer layer barrel body 11, and the barrel mouth of the inner layer barrel body 10 and the barrel mouth of the outer layer barrel body 11 are closed so that Inner layer barrel 10 and outer layer barrel 11 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com