Anti-lock system-based tyre burst braking system

An anti-lock braking system and braking system technology, applied in the direction of brakes, tire measurement, tire parts, etc., can solve the problems of increasing costs and process steps, reducing system response speed, and high production costs, so as to reduce production process steps, Simplified structure, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

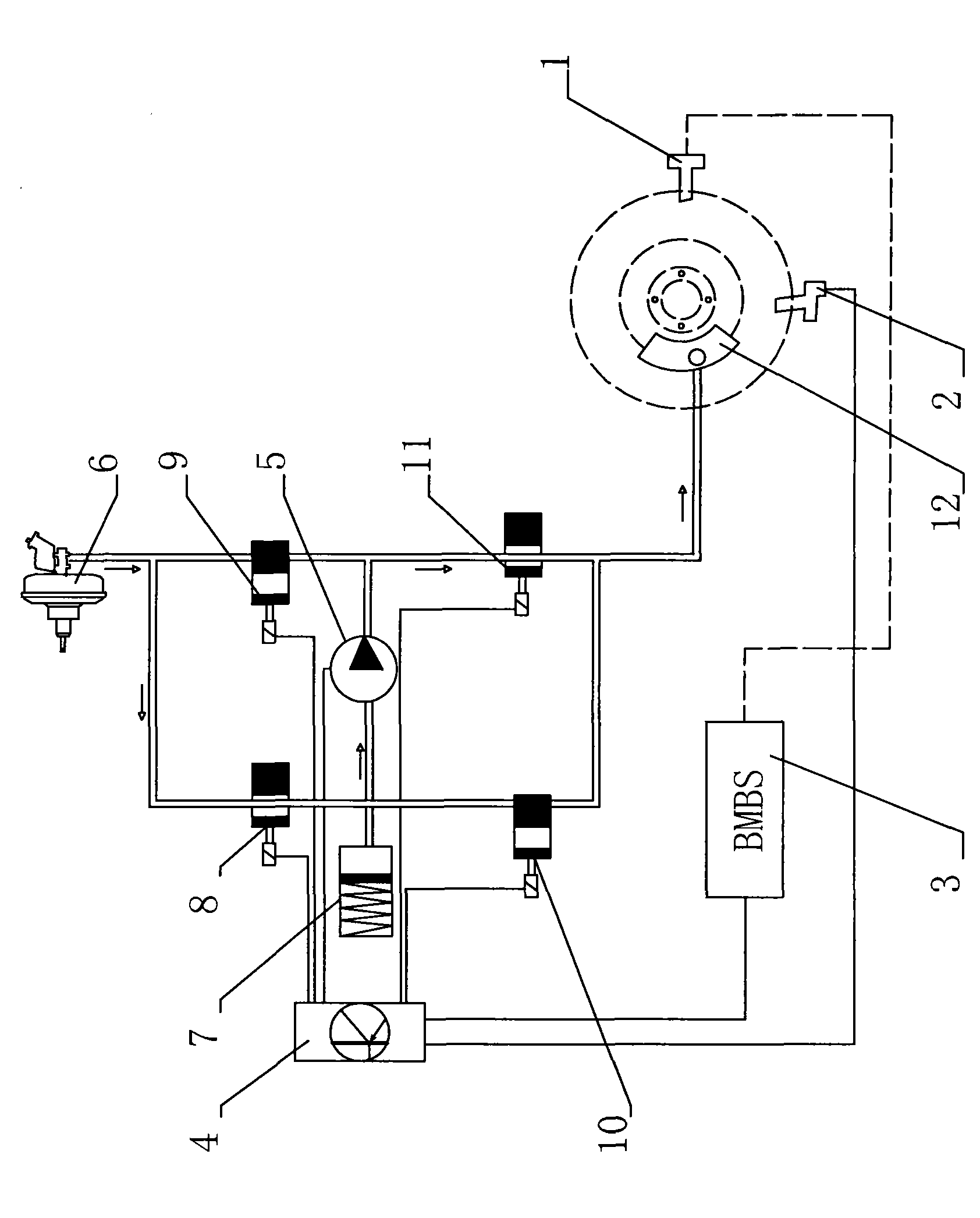

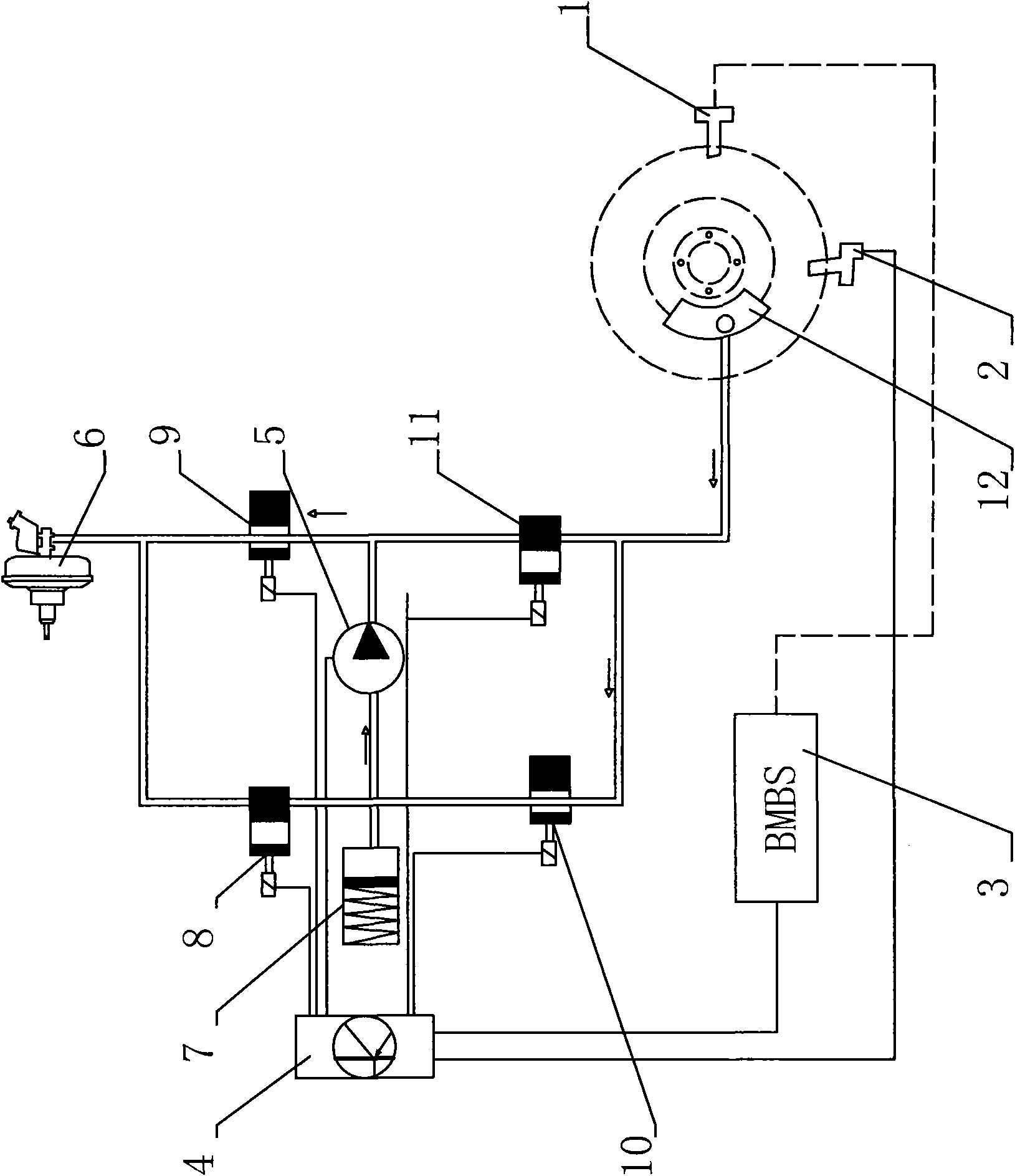

[0014] Such as figure 1 As shown, the present invention includes a tire pressure monitoring sensor 1 , a rotational speed sensor 2 , a braking system with ABS / ESP and a BMBS controller 3 . Both the power supply end of the braking system and the power supply end of the BMBS controller 3 are connected to the vehicle battery. The tire pressure monitoring sensor 1 is located in each wheel of the car, and it converts the air pressure value in the tire into an electrical parameter and transmits it to the BMBS controller 3 installed on the vehicle body through a wireless signal. The BMBS controller 3 has the function of data processing and analysis. The electronic control unit 4 of the braking system of ABS / ESP is connected. The brake system with ABS / ESP includes a pump motor 5, a hydraulic control unit and an electronic control unit 4. The hydraulic control unit includes an accumulator 7, an electromagnetic reversing valve 8, an electromagnetic isolation valve 9, a normally closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com