Technique for manufacturing highland barley malts

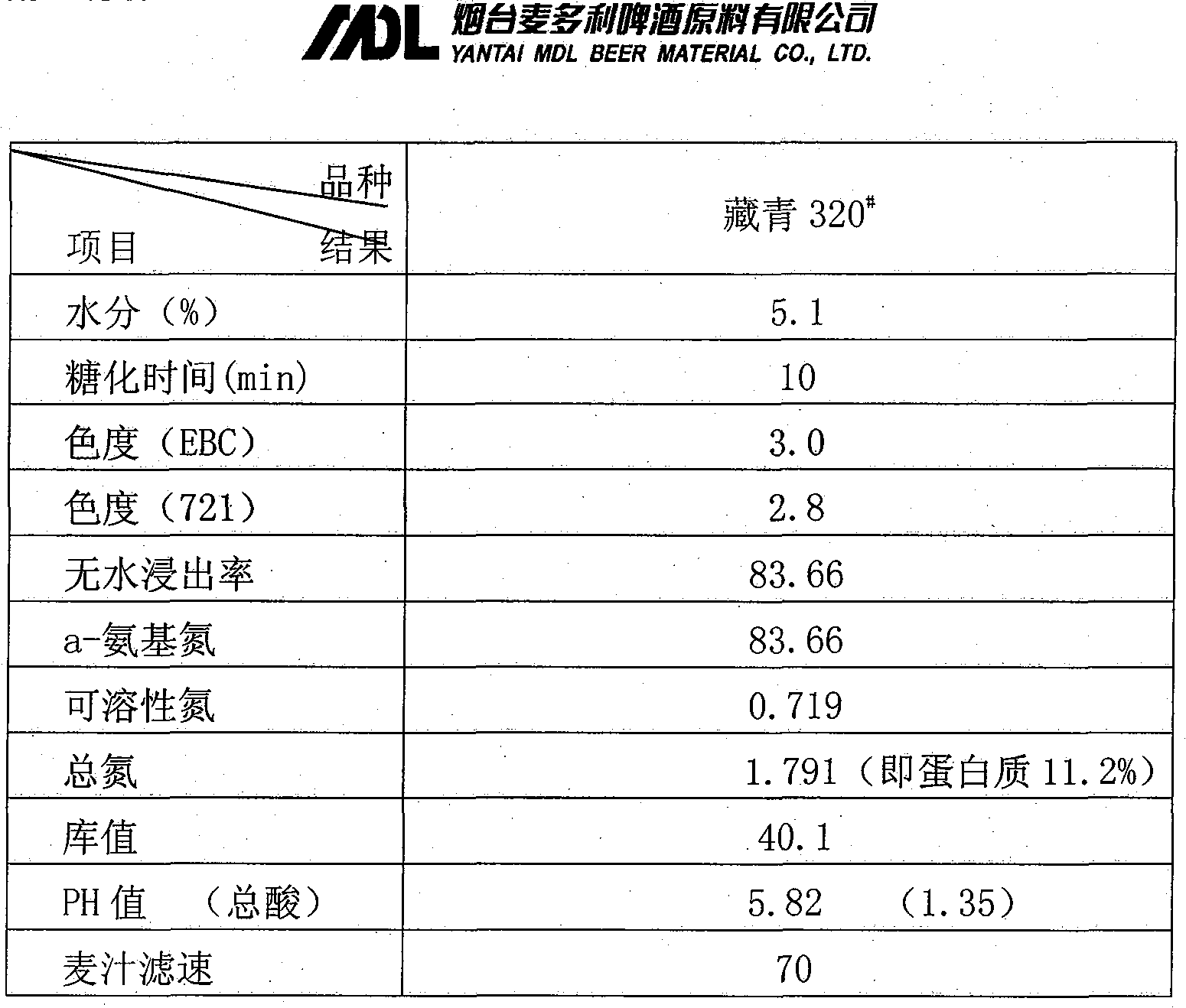

A highland barley malt and manufacturing process technology, applied in the field of the manufacturing process of Tibetan blue 320# malt, can solve problems such as highland barley malt that have not been seen, and achieve the effects of preventing anemia and vascular diseases, reducing levels, and reducing astringency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

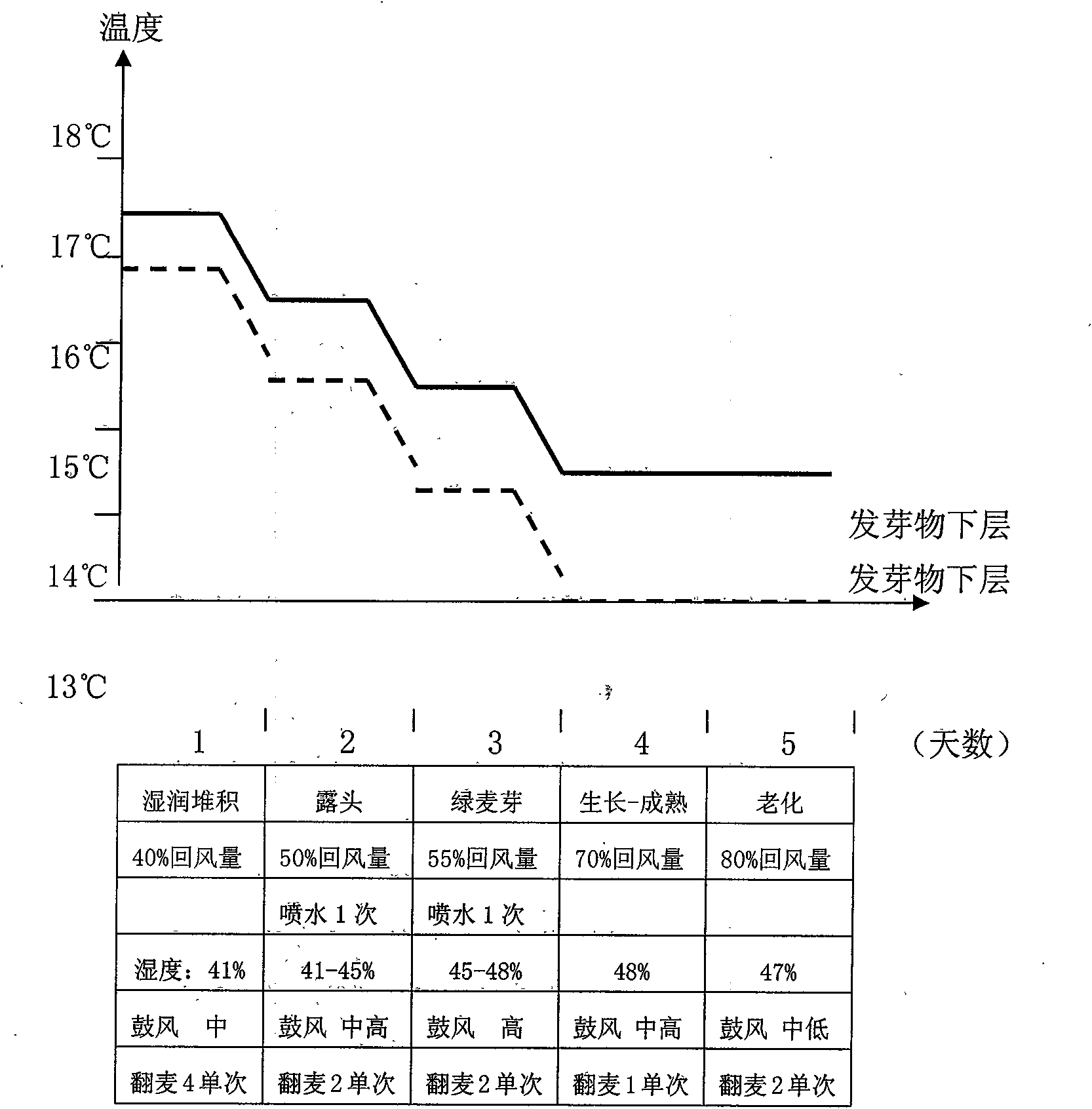

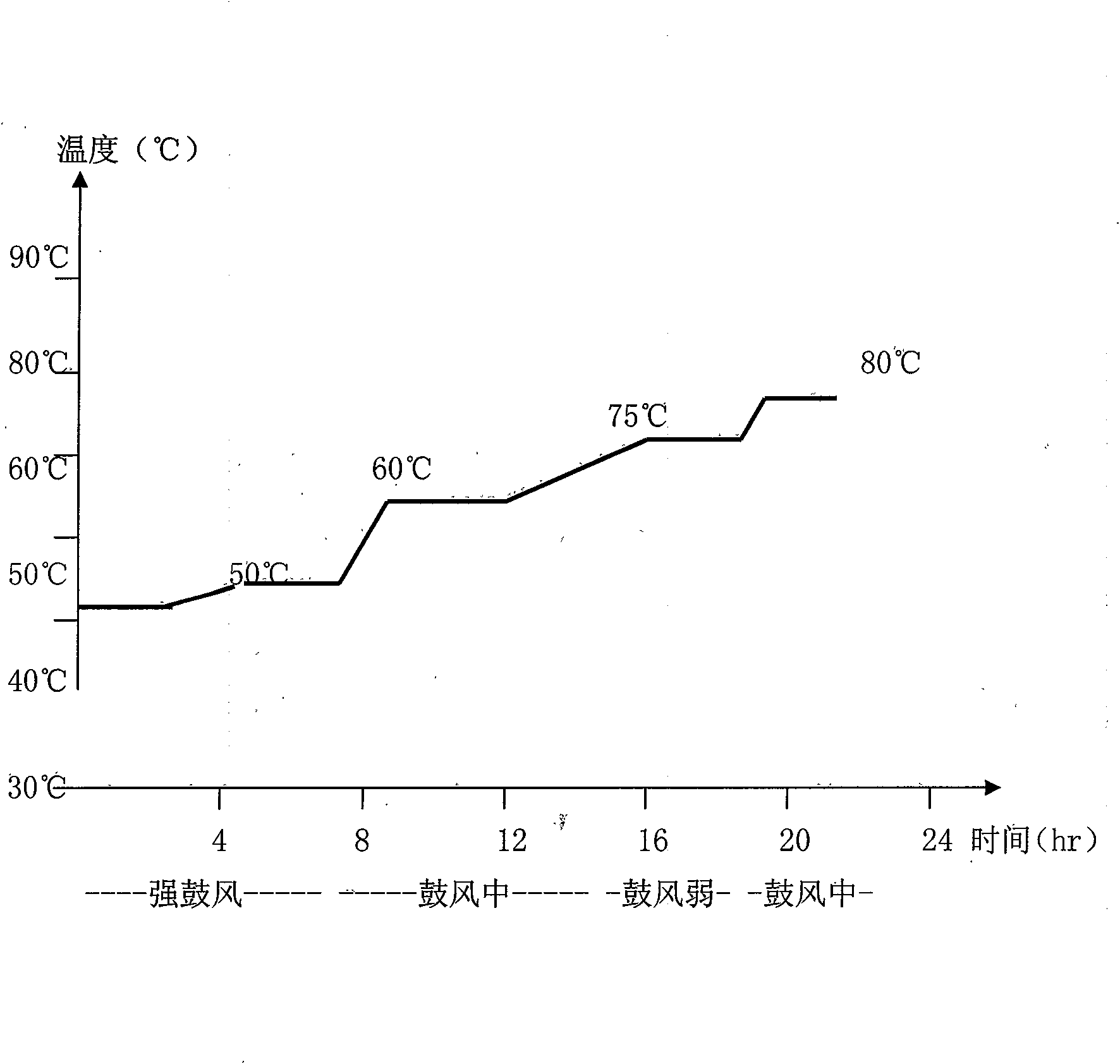

[0017] A production process of highland barley malt, characterized in that: the malting process comprises the following steps:

[0018] 1. Cleaning / grading:

[0019] Use 40 tons of Tibetan green 320# highland barley raw barley to remove dust, awns, iron filings, stones, weeds, miscellaneous wheat, and half or damaged wheat grains through barley roughing machines, selection machines, and classifiers. Select 30 tons of qualified barley barley.

[0020] 2. Soak wheat

[0021] The "intermittent soaking method" is adopted, that is, "soaking 8hr / breaking 13hr / soaking 3hr / breaking 5hr / soaking 3hr" wheat soaking process, and the total soaking time is 32 hours. During wet immersion, the temperature is controlled at 14°C, and the wheat immersion process is ventilated for 35 minutes per hour; during dry immersion, the temperature is controlled at 16°C, and when the water is cut off, the air is blown for 35 minutes per hour and then the air is sucked for 5 minutes. Repeat the operation ...

Embodiment 2

[0030] A production process of highland barley malt, characterized in that: the malting process comprises the following steps:

[0031] 1. Cleaning / grading:

[0032] Use 40 tons of Tibetan green 320# highland barley raw barley to remove dust, awns, iron filings, stones, weeds, miscellaneous wheat, and half or damaged wheat grains through barley roughing machines, selection machines, and classifiers. Select 30 tons of qualified barley barley.

[0033] 2. Soak wheat

[0034] The "soaking 8hr / breaking 13hr / soaking 3hr / breaking 5hr / soaking 3hr" wheat soaking process is adopted, and the total wheat soaking time is 32 hours. During wet immersion, the temperature is controlled at 14-17°C, and the process of wheat immersion is ventilated for 35 minutes per hour; during dry immersion, the temperature is controlled at 16-21°C, and when the water is cut off, the air is blown for 35 minutes per hour and then the air is sucked for 5 minutes. The temperature of the wheat layer is control...

Embodiment 3

[0041] A production process of highland barley malt, characterized in that: the malting process comprises the following steps:

[0042] 1. Cleaning / grading:

[0043] Use 50 tons of Tibetan green 320# highland barley raw barley to remove dust, awns, iron filings, stones, weeds, miscellaneous wheat and half or damaged wheat grains through barley roughing machines, selection machines, and classifiers. Select 30 tons of qualified barley barley.

[0044] 2. Soak wheat

[0045] The "soaking 8hr / breaking 13hr / soaking 3hr / breaking 5hr / soaking 3hr" wheat soaking process is adopted, and the total wheat soaking time is 32 hours. During wet immersion, the temperature is controlled at 17°C, and the wheat immersion process is ventilated for 35 minutes per hour; during dry immersion, the temperature is controlled at 21°C, and when the water is cut off, the air is blown for 35 minutes per hour and then the air is sucked for 5 minutes. Repeat the operation to control the temperature of the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com