Sugarcane seed cutting production line and work method thereof

A production line and sugarcane technology, applied in seed immunization, seed and rhizome treatment, application, etc., can solve the problems of high labor intensity, low production efficiency, and affecting the germination rate of sugarcane, and achieve the effect of improving production efficiency and ensuring the germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

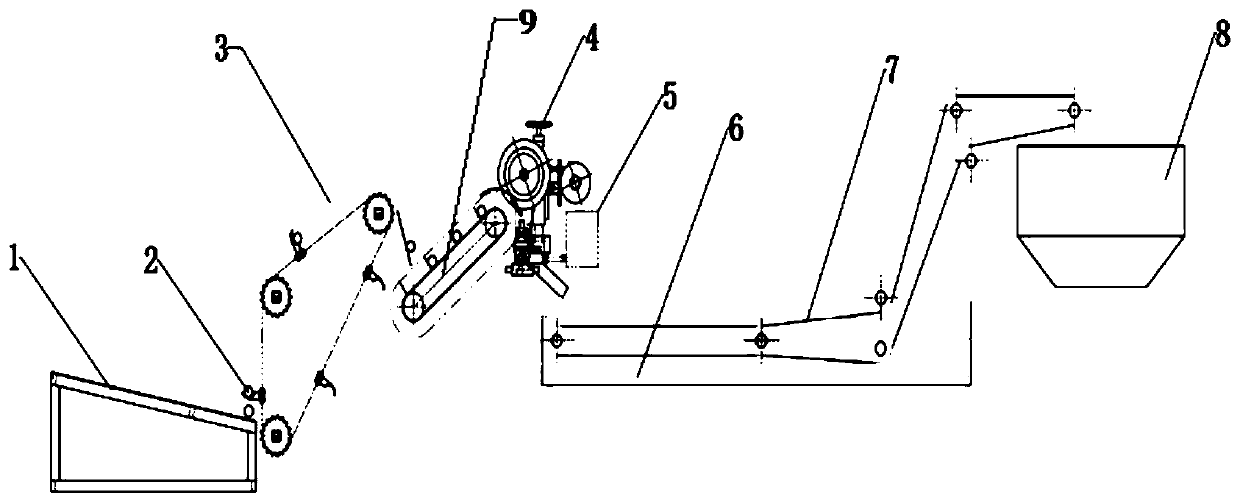

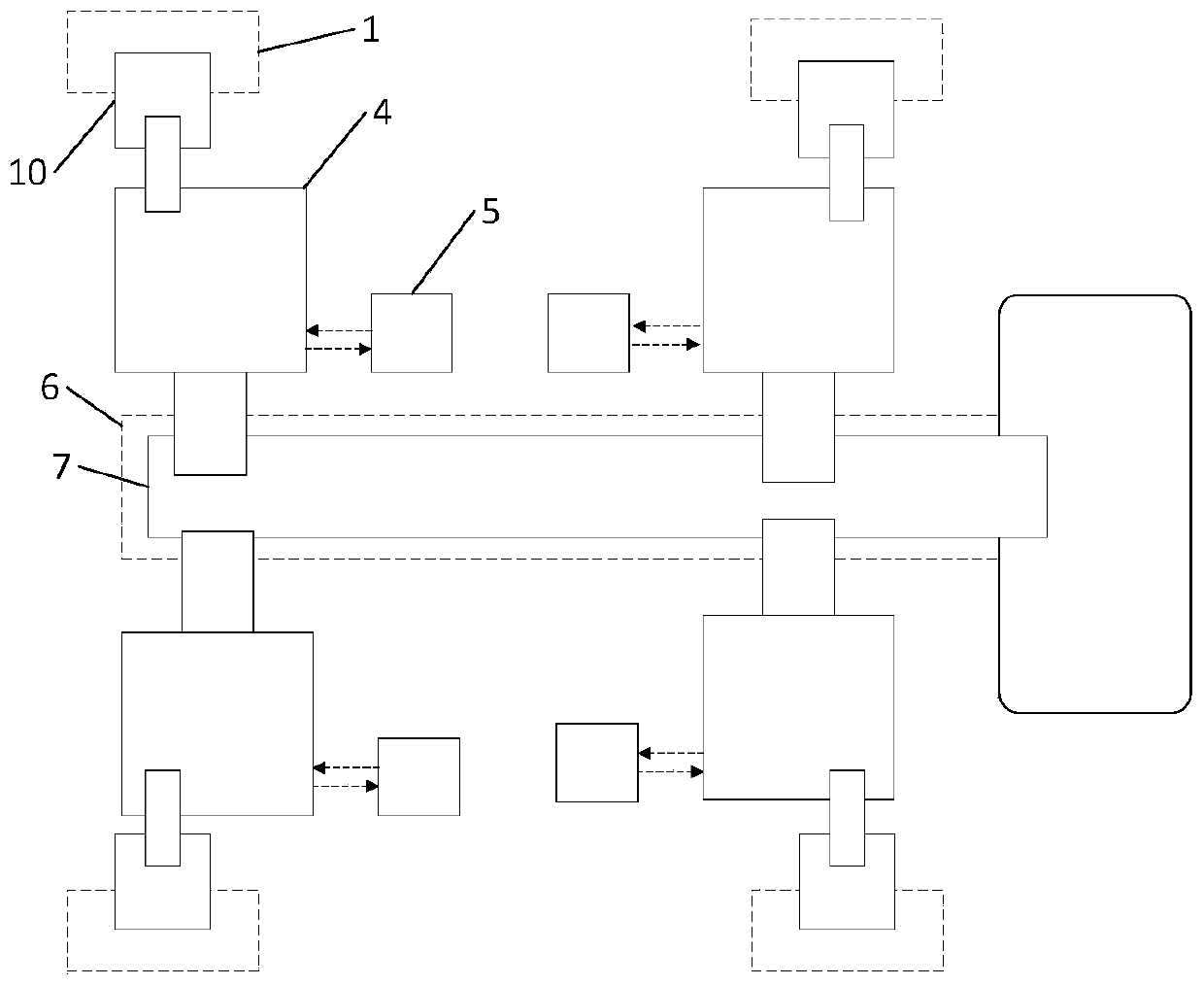

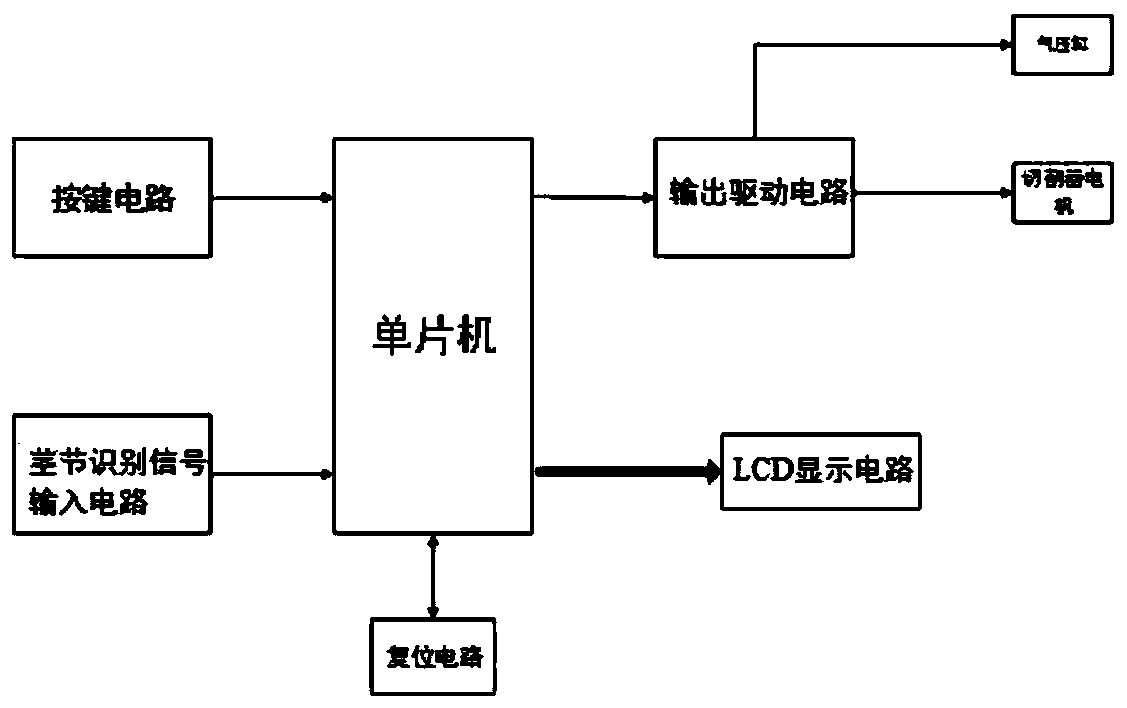

[0024] A sugarcane seed cutting production line, used for cutting cane seeds in batches, including a cane scooping device, an intelligent single-bud segment cutting machine, a cane seed conveying device and a cane collection box arranged in sequence along the conveying direction of sugarcane; it also includes a stem node identification system And a medicine pool with insect repellant liquid. The stem node recognition system is electrically connected with the intelligent single-bud cutting machine. The stem node recognition system recognizes the sugarcane stem nodes and feeds back to the intelligent single-bud cutting machine. The intelligent single-bud cutting machine completes the sugarcane cutting. The cut cane seeds are conveyed to the cane collecting box by the cane se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com