Edge detection device and line sensor for same

An edge detection device and a line sensor technology, applied in the field of line sensors, can solve the problem that it is difficult to correctly judge the detection, change of the edge part, and the increase in the degree of change of the light-receiving signal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

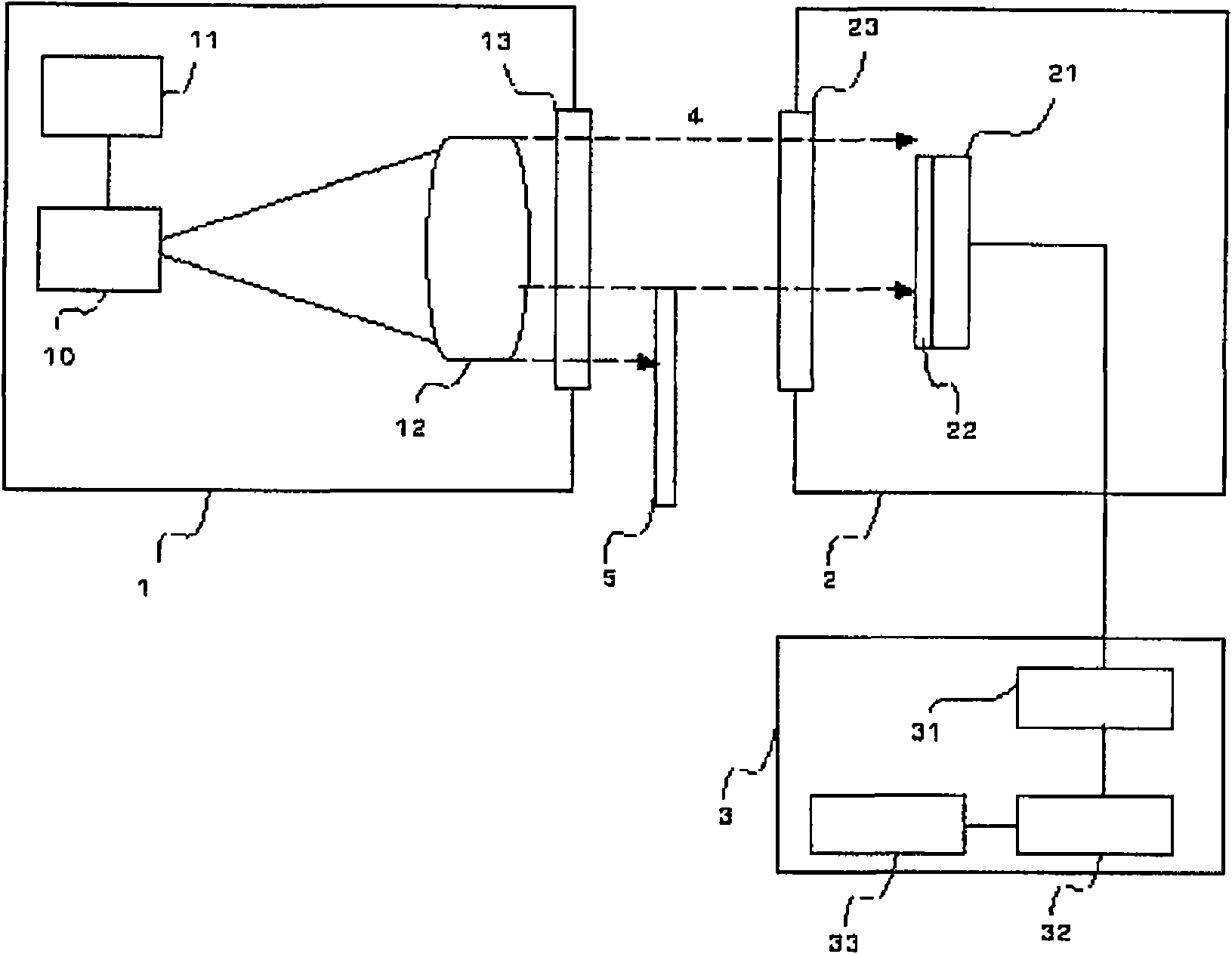

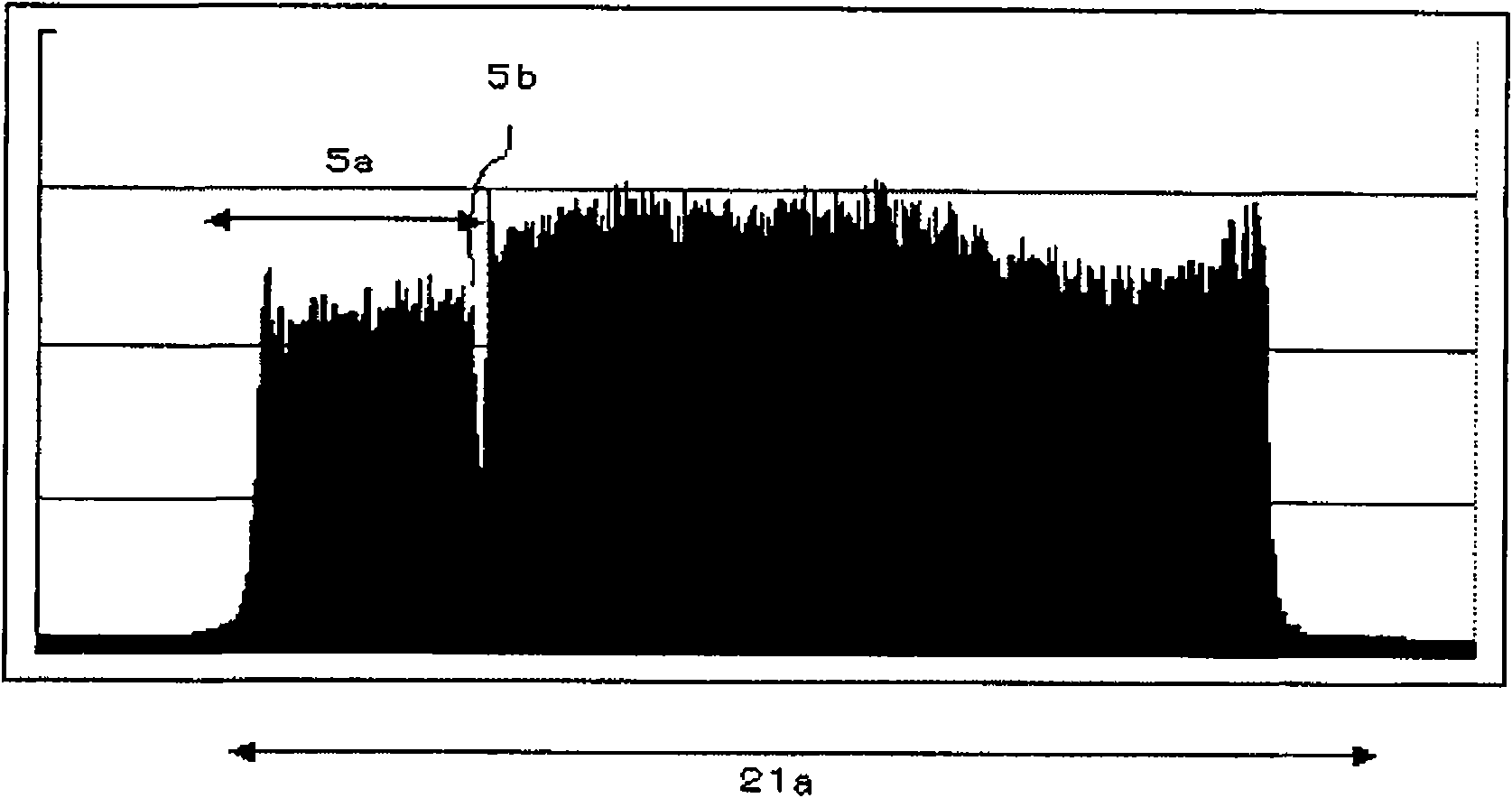

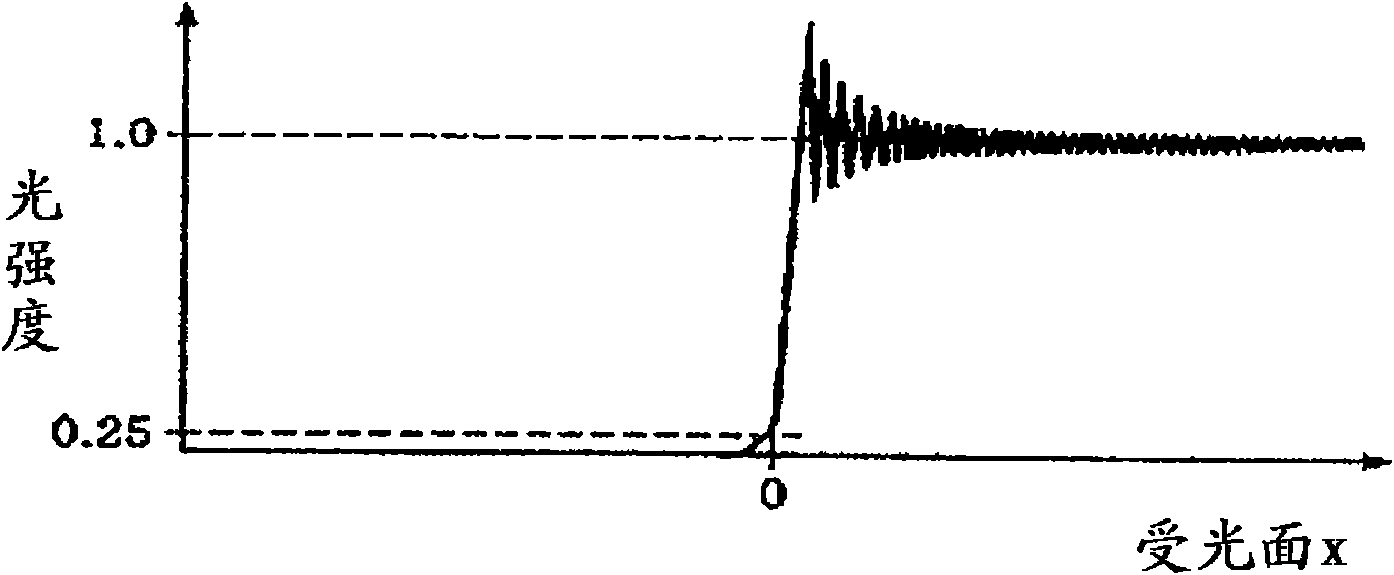

[0030] figure 1 It is a figure which shows the structure of the edge detection apparatus which concerns on embodiment of this invention. exist figure 1 In this embodiment, the edge detection device includes a light projector light emitting unit 1 , a light receiver light receiving unit 2 , and an edge detection unit 3 . The light projecting part 1 of the light emitter is disposed opposite to the light receiving surface of the light receiving window 23 of the light receiving part 2 of the light receiver, and has a light source 10 composed of a laser diode (LD), a driver IC 11 for controlling the light source 10, a light projecting lens 12 and a light projecting lens 12. window 13. The light projecting lens 12 emits and outputs the monochromatic light generated by the light source 10 to the middle part of the line sensor 21 of the light receiver 2 through the light projecting window 13 . Here, the monochromatic light refers to light having a wavelength distribution characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com