Device and method for detecting transmittance of thin film polarizer

A thin-film polarizer and detection device technology, which is applied in the laser field, can solve the problems that the transmittance of thin-film polarizers cannot be accurately tested, and achieve the effects of improving measurement accuracy, avoiding measurement errors, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

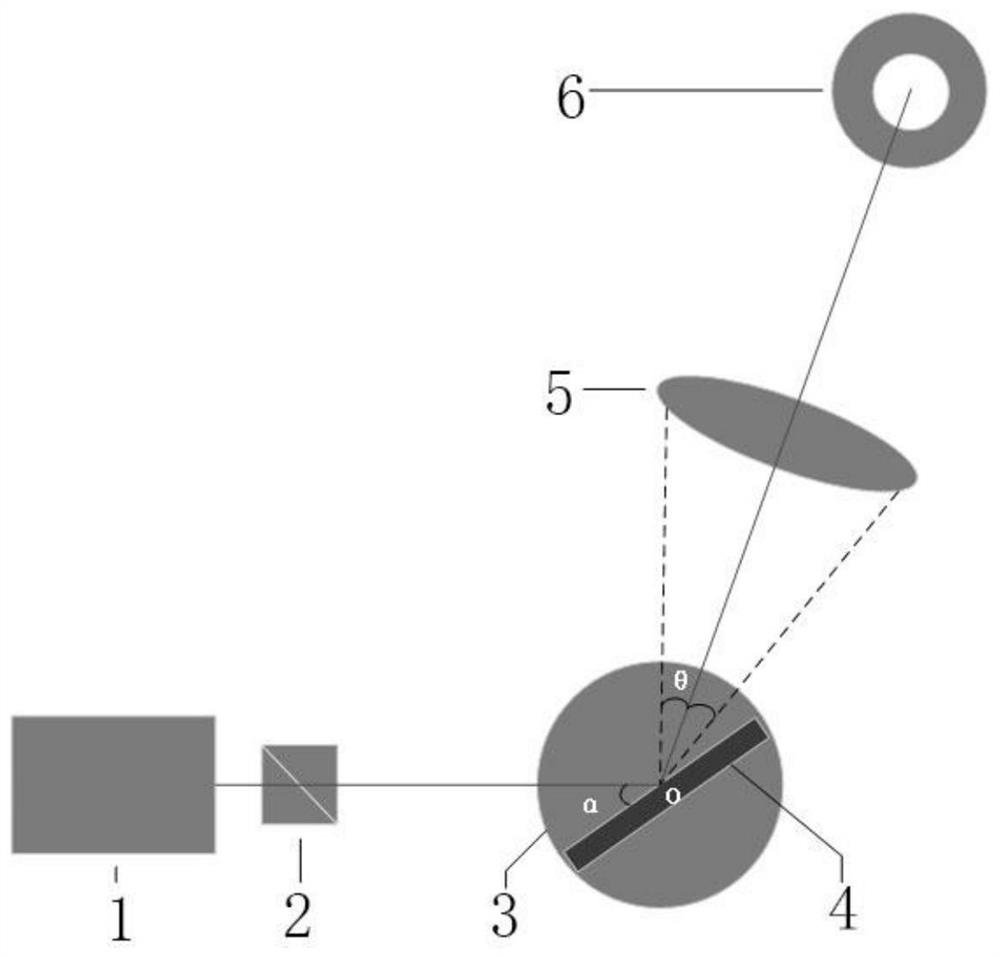

[0029] A detection device for the transmittance of a thin-film polarizer, comprising a test light source 1, a polarization cube 2, a rotary table 3, a mounting base 4, a convex lens 5 and a power meter 6, the mounting base 4 is fixedly arranged on the rotary table 3 and two The center of the film polarizer to be tested is set on the mount 4 and the centers of the two are coincident. The light emitted by the test light source 1 passes through the polarization cube 2, is incident on the film polarizer to be tested, and is reflected by the film polarizer to be tested. To the center of the convex lens 5, and then reach the power meter 6, the angle α between the light emitted by the test light source 1 and the plane where the film polarizer to be tested is located is 33 ± 1 °, and the focal length of the convex lens 5 is f, so The distance between the center of the convex lens 5 and the center of the turntable 3 and the distance between the center of the convex lens 5 and the power ...

specific Embodiment approach 2

[0034] A method for detecting the transmittance of a thin film polarizer using the detection device described in Embodiment 1, comprising the following steps:

[0035] Step 1, fixing the mounting base 4 at the rotation center point O of the rotary table 3, and then setting the film polarizer to be measured at the center of the mounting base 4;

[0036] Step 2. Place the test light source 1 and turn it on, so that the light emitted by it is incident on the center of the film polarizer to be tested, and the rotating table 3 is turned so that the light emitted by the test light source 1 is between the plane of the film polarizer to be tested. The included angle α is 33±1°;

[0037] Step 3, place the polarizing cube 2 and the convex lens 5, so that the light emitted by the test light source 1 passes through the center of the polarizing cube 2, the film polarizer to be tested, and the convex lens 5 in sequence;

[0038] Step 4, adjust the position of the convex lens 5 so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Clear aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com