Biodegradable vascular support

A biodegradable and biological technology, applied in medical science, surgery, coating, etc., can solve problems such as uncontrolled, delayed stent incorporation, and affecting blood flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0226] The stent according to the invention consists of:

[0227] 90% (w / w) zinc

[0228] 6% (w / w) magnesium

[0229] 1% (w / w) calcium

[0230] 2% (w / w) yttrium

[0231] 1% (w / w) other metals, metal salts, non-metals (carbon, sulfur, nitrogen, oxygen, hydrogen).

[0232] The stent according to Example 1 was coated by dipping with a solution of polyethylene glycol and doxorubicin. After drying, repeat the impregnation process two more times.

example 2

[0234] The stent according to the invention consists of:

[0235] 46% (w / w) zinc

[0236] 46% (w / w) magnesium

[0237] 6% (w / w) yttrium

[0238] 2% (w / w) other metals, metal salts, non-metals (carbon, sulfur, nitrogen, oxygen, hydrogen).

[0239] At intervals, the stent according to Example 2 was coated with a solution of polylactide and the active agent paclitaxel in chloroform in a spray method. After drying, the polymer coating is melted at discontinuities by means of temperature sensors in order to form holes. Subsequently, the wells were filled with paclitaxel in DMSO and dried.

example 3

[0241] The stent according to the invention consists of:

[0242] 75% (w / w) zinc

[0243] 15% (w / w) calcium

[0244] 4% (w / w) yttrium

[0245] 0.7% (w / w) manganese

[0246] 0.8% (w / w) iron

[0247] 4.5% (w / w) other metals, metal salts, non-metals (carbon, sulfur, nitrogen, oxygen, hydrogen).

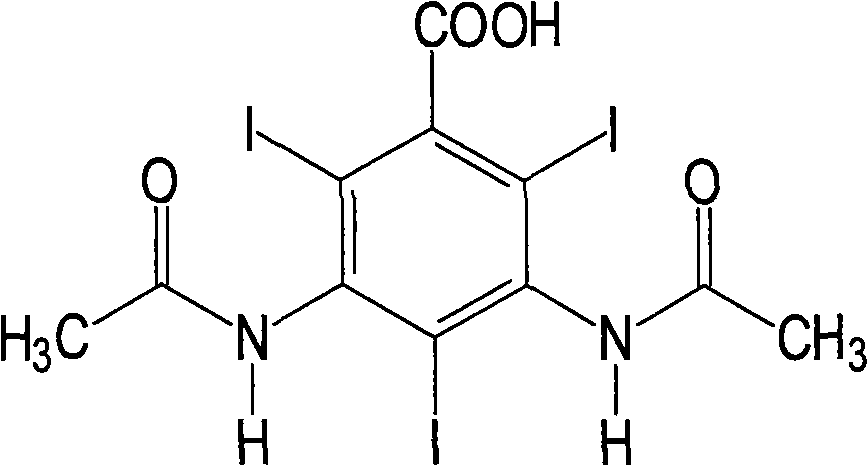

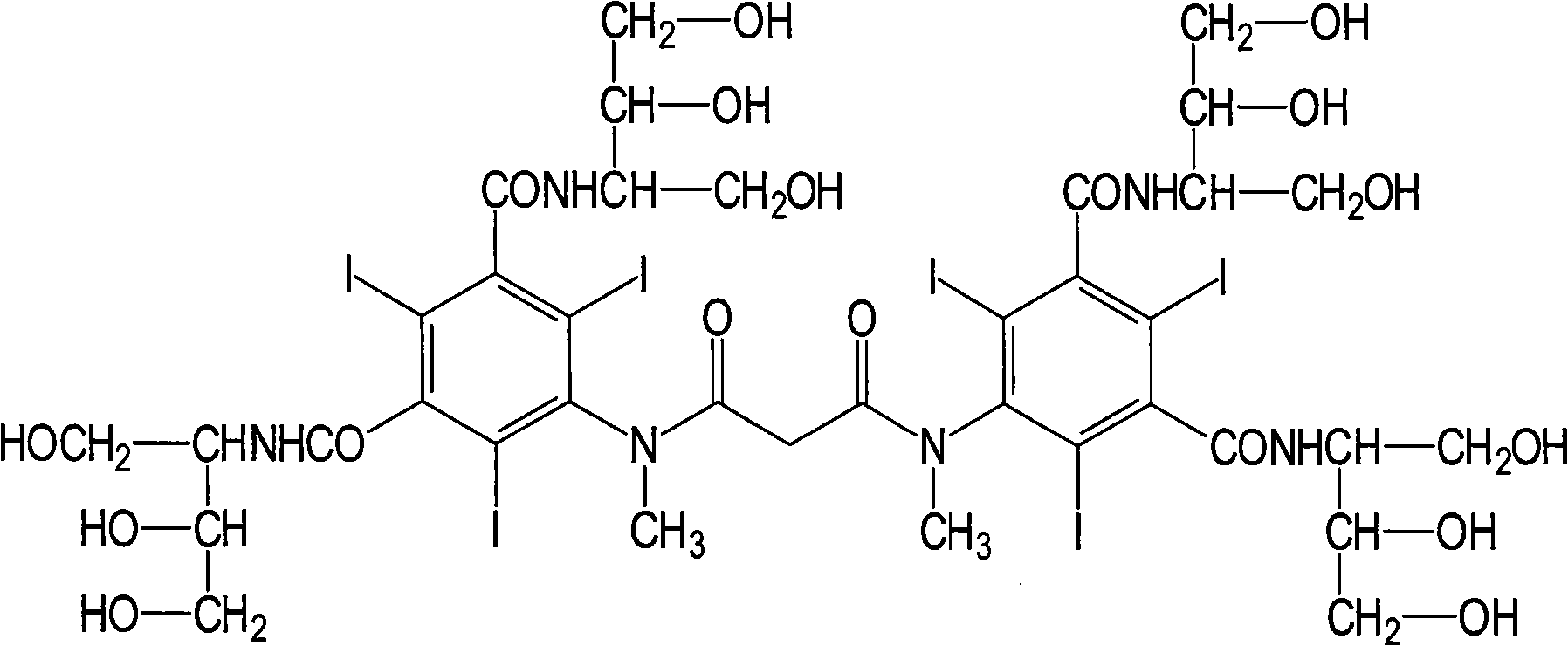

[0248] At intervals, the stent according to example 3 was coated with a solution of polygluconate in dichloromethane in a spray method. After drying, the polymer coating is melted at the discontinuities by means of acid treatment in order to form pores. After complete removal of possible residual acid by several washes and drying of the scaffold, the holes are filled with the aid of a pipette with an ethanol solution containing 30% by weight of paclitaxel and the contrast agent iopromide. Subsequently, drying is carried out at room temperature under a gentle air flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com