Method for processing multilayer flexible circuit board

A technology of flexible circuit boards and processing methods, which is applied in multilayer circuit manufacturing, printed circuit, printed circuit manufacturing, etc., can solve problems affecting processing quality, expansion and contraction of inner layer circuit board copper foil, cover film bubbles, etc., to reduce The effect of drilling position deviation probability, improving single product yield, and reducing the probability of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments.

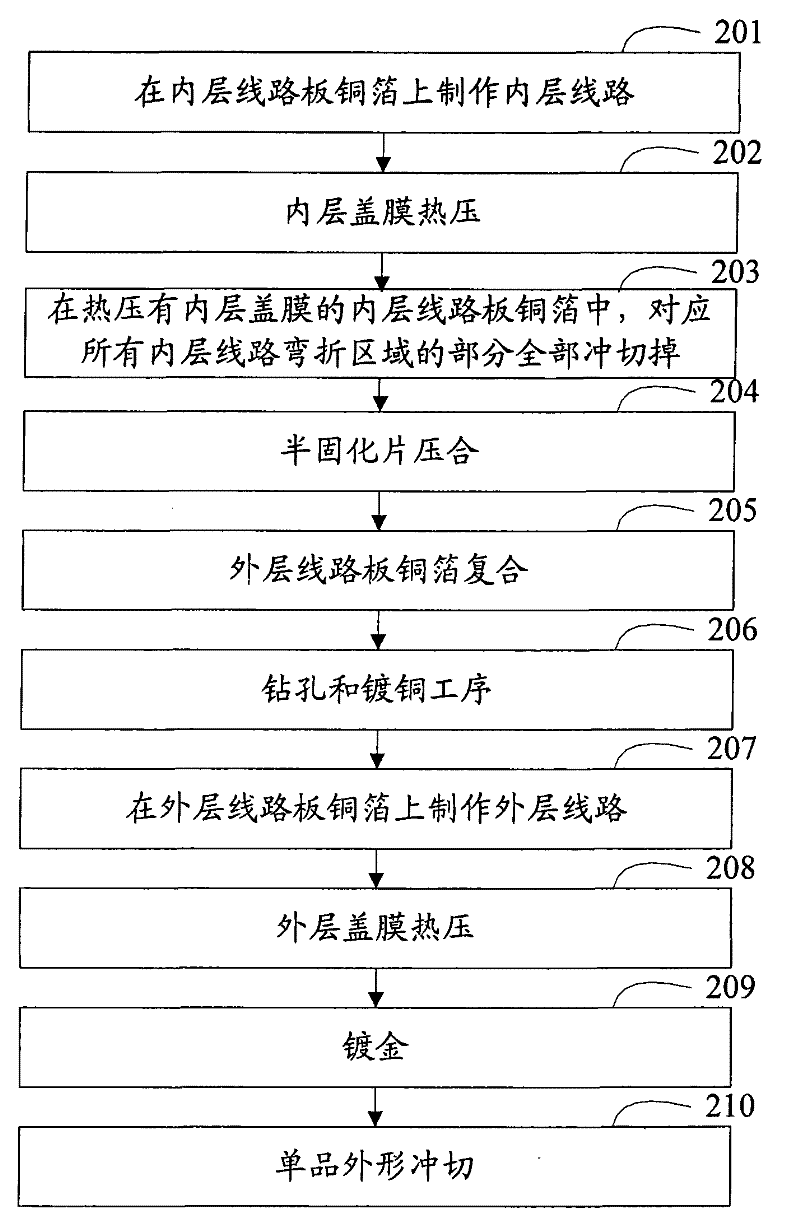

[0069] Figure 5 It is a schematic flow diagram of the method for processing a multilayer flexible circuit board in the present invention. Such as Figure 5 As shown, the processing method of the multilayer flexible circuit board in the present invention includes the following steps:

[0070] In step 501, multiple single-product inner-layer circuits are made on the copper foil of the inner-layer circuit board.

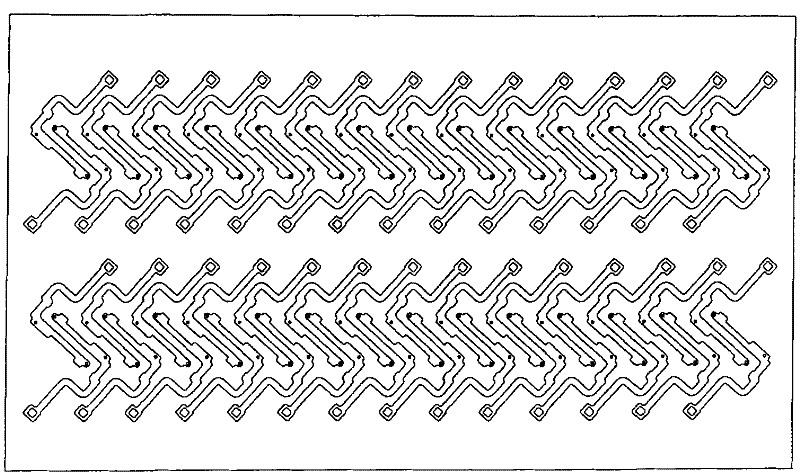

[0071] This step can specifically include dry film lamination, exposure, development, and etching. The inner circuit board copper foil processed by this step contains multiple single-product inner circuit and inner circuit board copper foil. Please refer to the layout styles of multiple inner lines on the image 3 .

[0072] In practical appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com