Rotary structure for full-automatic non-standard conveying equipment

A technology of conveying equipment and rotary structure, which is applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc. It can solve the problems of inability to transport fluid objects, inability to perform buffer rotation, etc., and achieve the effect of strengthening strength and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

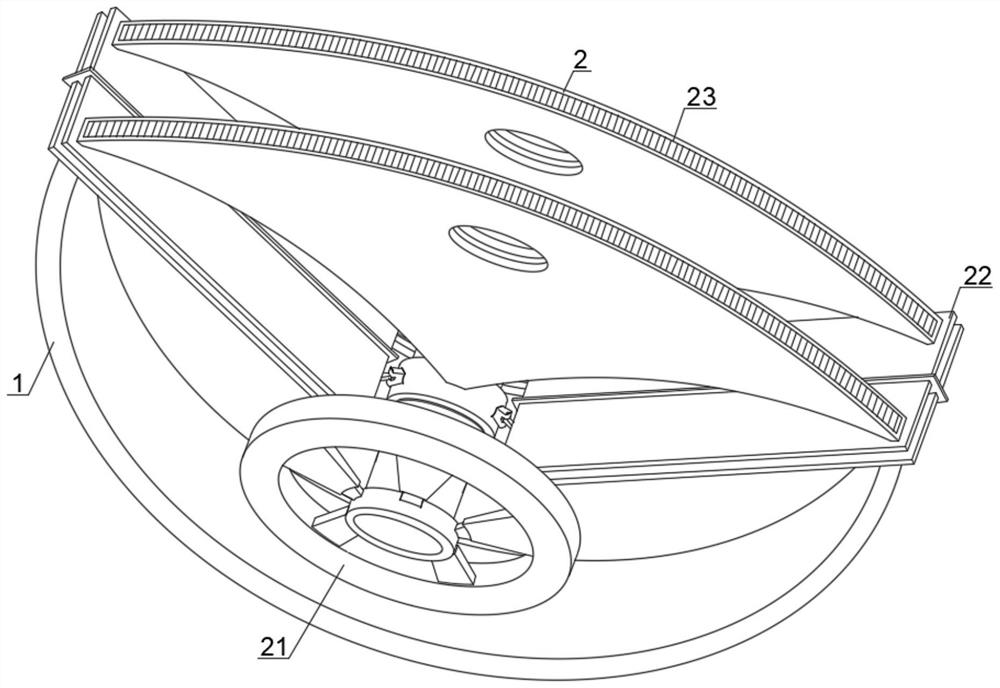

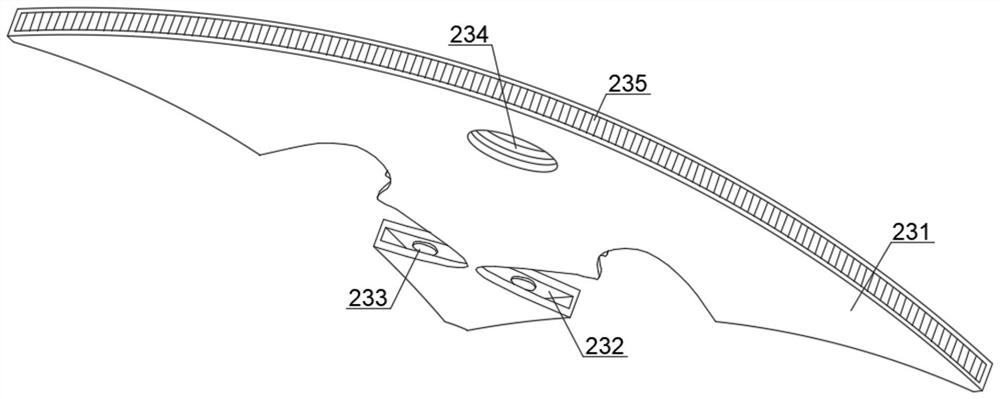

[0035] A rotary structure for fully automatic non-standard conveying equipment, including an elastic stretching mechanism 1 and a rotary mechanism 2, the two ends of the elastic stretching mechanism 1 are combined with both sides of the rotary mechanism 2, the rotary mechanism 2 includes a rotary mechanism 21, The mechanism 22 and the telescopic fan 23, the outer ring of the rotating mechanism 21 is socketed with the driving mechanism 22, and the driving mechanism 22 is movably connected by the telescopic fan 23. The telescopic fan 23 includes a fan plate 231, an inner cavity 232, and a built-in elastic piece 233 , through holes 234 and edge sieve grooves 235, the inner cavity of the fan plate 231 is provided with an inner cavity 232, and the upper wall of the inner cavity 232 is laid with a built-in elastic sheet 233, and the middle of the fan plate 231 is provided with a through hole 234, and the fan plate 231 is provided with a transparent hole 234. The outer wall of the pla...

Embodiment 2

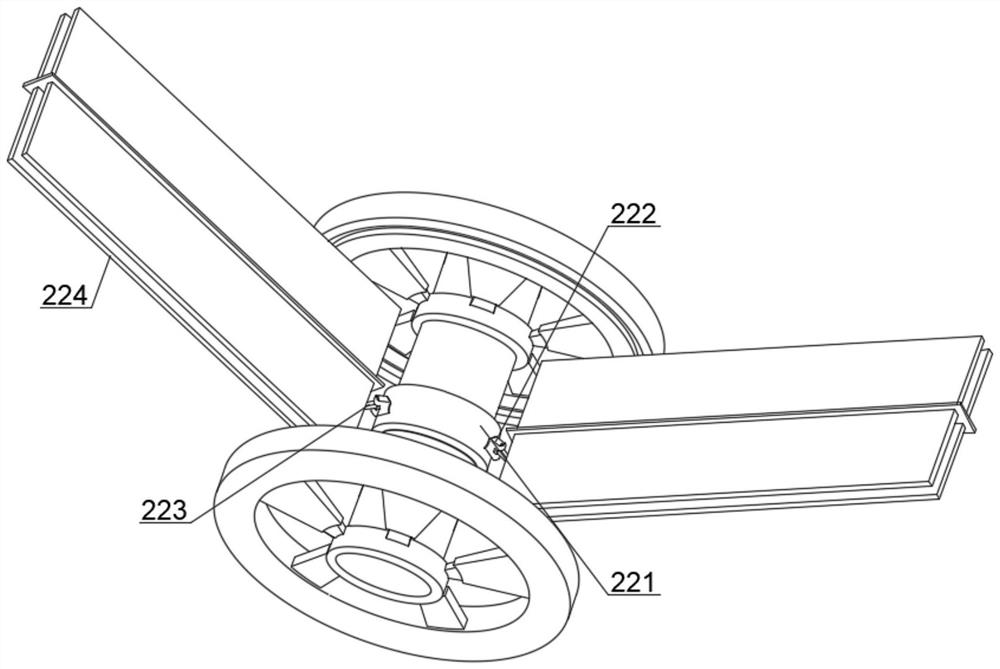

[0037]A rotary structure for fully automatic non-standard conveying equipment. The driving mechanism 22 includes a sleeve ring 221, edge ear pieces 222, connecting rod 223 and a rotary baffle 224. The outer ring of the sleeve ring 221 is oppositely provided with two sets of edge ear pieces 222. , the outer end of the edge ear piece 222 is movably connected with the rotary baffle 224 through the connecting rod 223, the rotary baffle 224 includes a connecting strip 2241, an overhanging blocking piece 2242 and an elastic connecting piece 2243, and both sides of the connecting strip 2241 are provided Two sets of overhanging baffles 2242 are connected by an elastic connecting piece 2243, and the fluid object is placed on one side of the overhanging baffles 2242. At this time, the fluid object impacts on the overhanging baffles 2242 toward the inner end. Through the elastic connecting piece 2243, the overhanging blocking piece 2242 is elastically blocked when it is impacted, and the ...

Embodiment 3

[0039] A rotary structure for fully automatic non-standard conveying equipment. The rotary mechanism 21 includes a rotary wheel 211, a sliding inner groove 212, an inner connecting rod 213, an inner connecting ring 214 and a connecting cylinder 215. The inner end of the rotary wheel 211 is provided with a sliding inner Groove 212, the inner connecting rod 213 is arranged in an annular array on the inner cavity wall of the rotary wheel 211, the other end of the inner connecting rod 213 is connected with the inner connecting ring 214, and the inner connecting ring 214 is connected through the connecting cylinder 215, and the connecting cylinder 215 includes a cylindrical body 2151, the inner snap ring 2152 and the inner extension block 2153, the cylinder body 2151 is connected in series through the inner snap ring 2152, the upper and lower ends of the inner snap ring 2152 are provided with an inner extension block 2153, and the inner extension block 2153 is movable with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com