Continuously-wound single-phase large-size iron core and fabrication method thereof

An iron core and single-phase technology, which is applied in the field of structural improvement of single-phase iron core, can solve the inconsistency between the high magnetic permeability direction of the material and the direction of the magnetic circuit, the complicated assembly method of the wound single-phase iron core, and the insufficient tightness of the material tape, etc. problem, to achieve the effect of saving intellectual activities, compact magnetic circuit, and reducing the hollow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

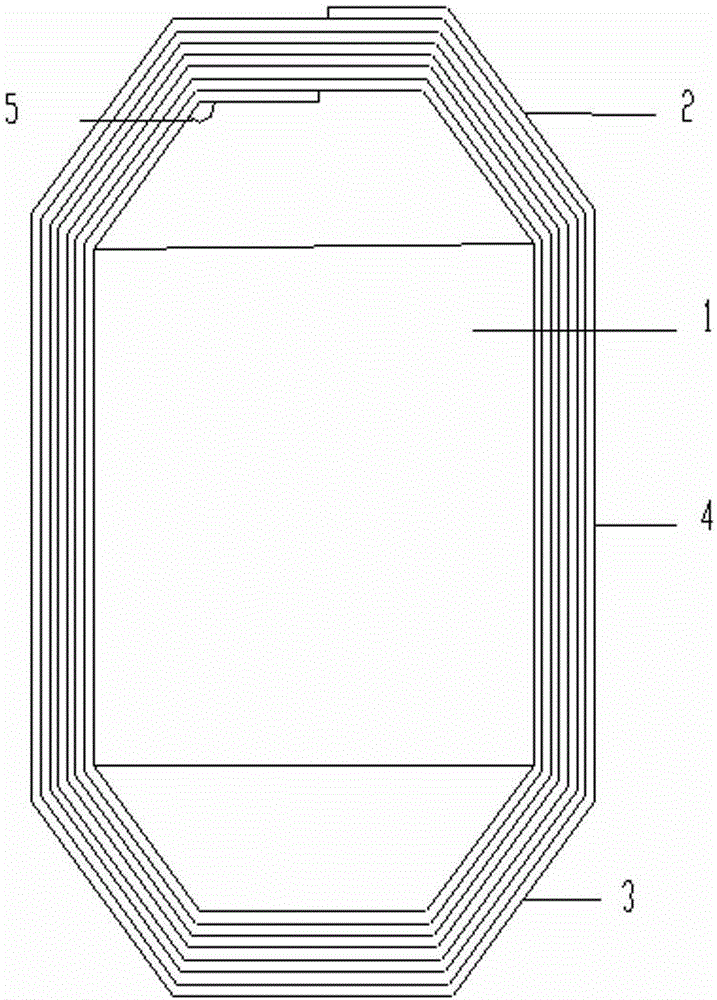

[0055] Such as figure 2 As shown, this embodiment is a schematic structural diagram of a single-layer arrangement of single-phase iron cores P-M-P-N-P-M-P-N with eight 135° bending angles. Direction edge 7, bending edge 6, core column 2, bending edge 6, horizontal direction edge 7, bending edge 6, core column 2,. The remaining layers are wound continuously in the above-mentioned manner.

Embodiment 2

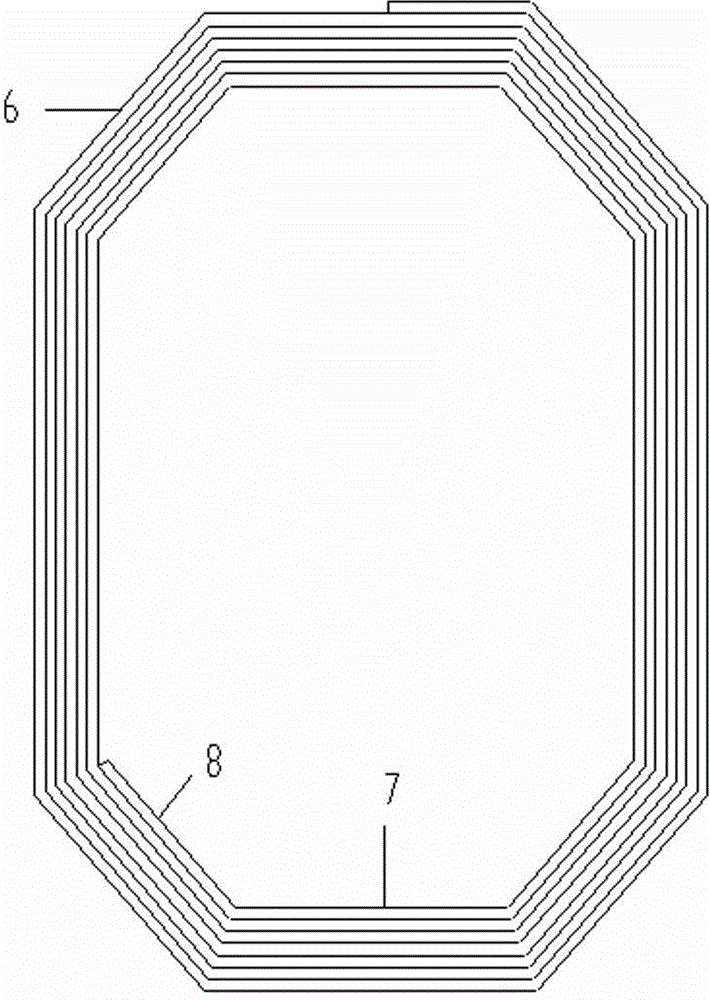

[0057] Such as image 3 As shown, this embodiment is a schematic structural diagram of a single-layer arrangement of single-phase iron cores P-N-P-M-P-M-P-N with eight 135° bending angles. Column 2, bending edge 6, horizontal edge 7, bending edge 6, core column 2, bending edge 6, horizontal edge 7. The remaining layers are wound continuously in the above-mentioned manner.

Embodiment 3

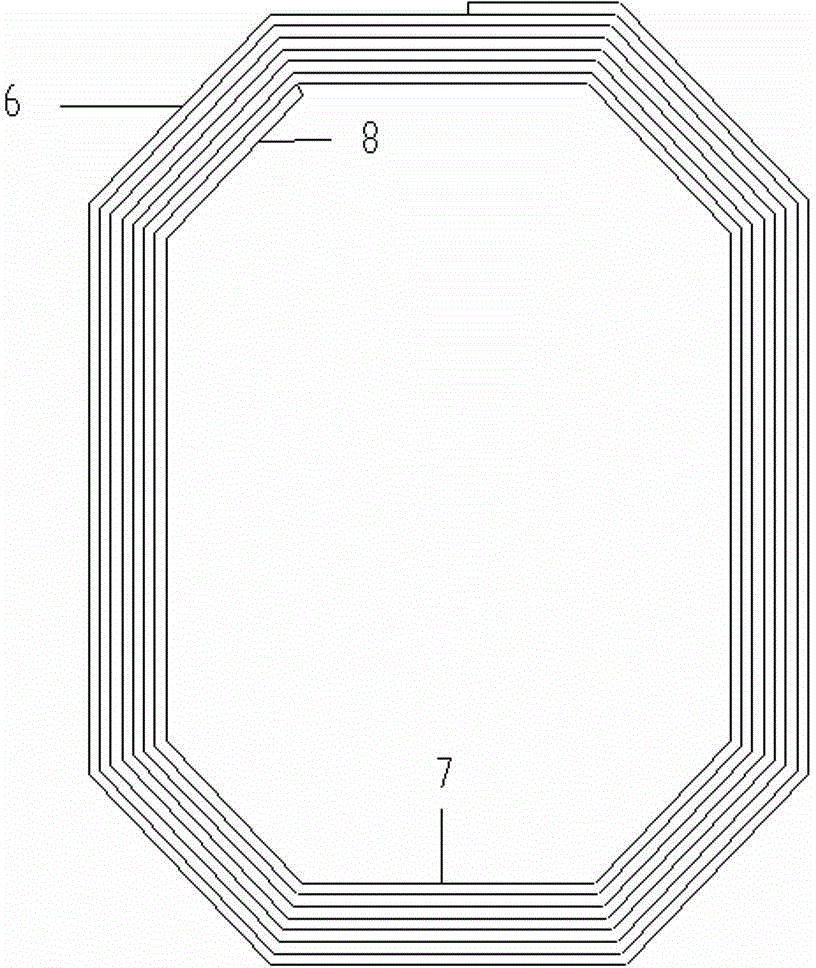

[0059] Such as Figure 4 As shown, this embodiment is a schematic structural diagram of a single-layer arrangement of single-phase iron cores P-P-M-P-P-N-P-P-M-P-P-N with twelve 150° bending angles. The starting edge is the first bending edge 8, and the single-layer strips are connected sequentially Bend edge 6, horizontal edge 7, bend edge 6, bend edge 6, core 2, bend edge 6, bend edge 6, horizontal edge 7, bend edge 6, bend edge 6, core Column 2,. The remaining layers are wound continuously in the above-mentioned manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com