Glass heat insulation paint of water-based hydroxyl polyurethane resin and preparation method thereof

A technology of hydroxyl polyurethane and thermal insulation coatings, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

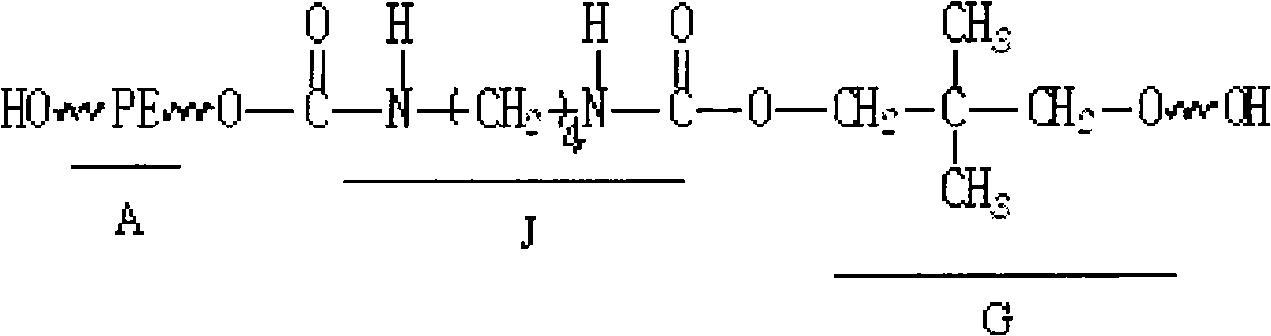

[0040] (1) Under the protection of nitrogen, combine 10.600g isophthalic acid-5-sodium sulfonate, 35.157g adipic acid, 29.274g neopentyl glycol, 11.844g 2-ethyl-2-butyl 1,3- Propylene glycol was put into a four-neck reactor with stirring, nitrogen gas pipe, thermometer, condenser and water separator, heated to 140°C, stirred, slowly heated to 200°C, and kept at 200°C for 1 hour. Start to measure the acid value. When the acid value drops to 5mgKOH / g resin, the xylene is removed under vacuum at 100℃, the vacuum degree is ≥0.040Kpa, the temperature is 50-80℃, and the vacuum is dried under reduced pressure for 1-2 hours to obtain the hydrophilic type. Hydroxy-terminated polyester (A).

[0041] (2) Add 20.12g of the above hydrophilic hydroxyl-terminated polyester (A), 5.248g of 1,4-cyclohexanedimethanol, and 2.844g of trimethylolpropane to a stirrer, thermometer, nitrogen gas pipe, and condenser. In the four-neck reactor under 110℃, first vacuum pump for 1 hour, and the vacuum degree...

Embodiment 2

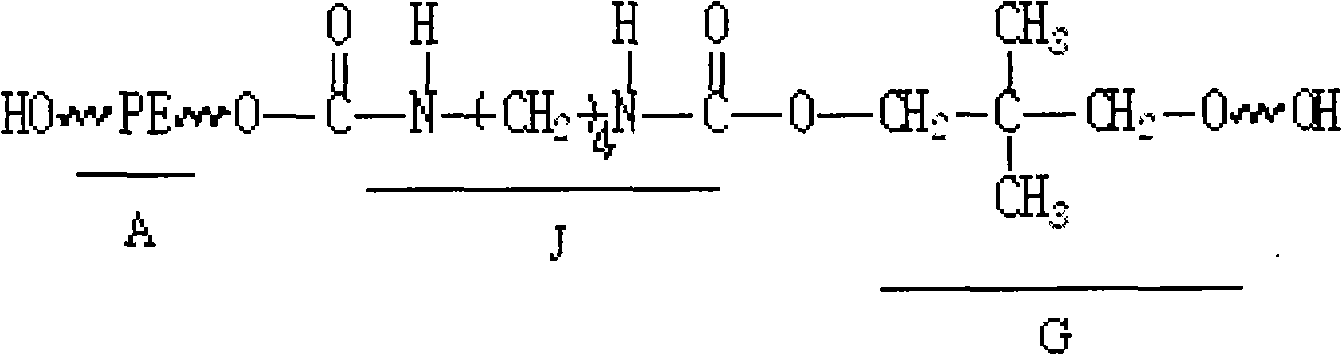

[0057] (1) Under the protection of nitrogen, put 12.630g isophthalic acid-5-sodium sulfonate, 48.147g isophthalic acid, 29.247g 1,4-butanediol, 11.634g hexanediol into a stirring, In a four-neck reactor consisting of a thermometer, a nitrogen gas pipe, a condenser tube and a water separator, the temperature was raised to 140°C, stirred, and slowly raised to 200°C, and kept at 200°C for 1 hour. Start to measure the acid value. When the acid value drops to 5mgKOH / g resin, the xylene is removed under vacuum at 100℃, the vacuum degree is ≥0.040Kpa, the temperature is 50-80℃, and the vacuum is dried under reduced pressure for 1-2 hours to obtain the hydrophilic type. Hydroxy-terminated polyester (A).

[0058] (2) Add 21.150g of the above hydrophilic hydroxyl-terminated polyester (A), 8.247g of 2-ethyl-2-butyl 1,3-propanediol, and 3.244g of trimethylolpropane to a stirrer, thermometer, In a four-port reactor with nitrogen gas duct and condenser, at 110°C, vacuum pump water for 1 hour ...

Embodiment 3

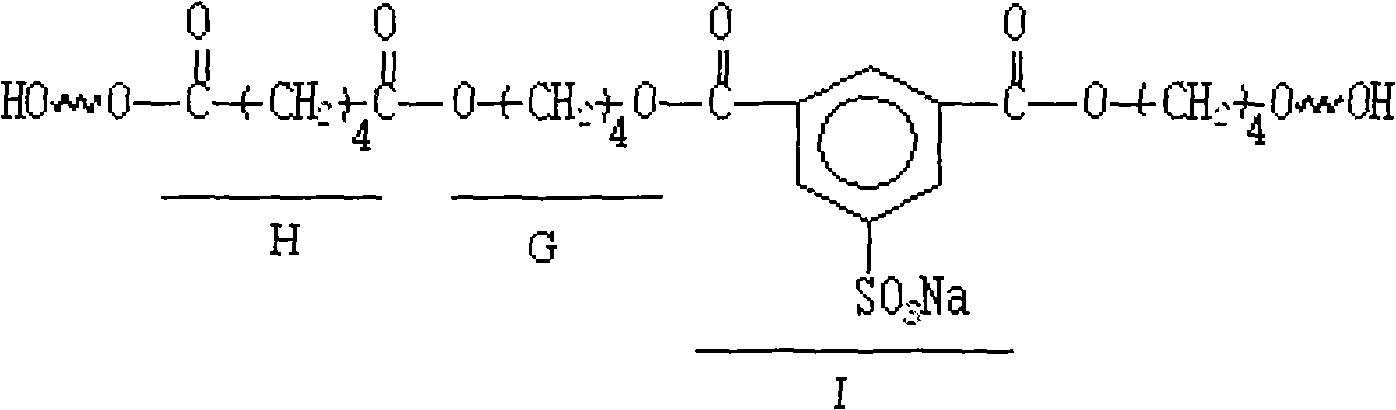

[0073] (1) Under the protection of nitrogen, put 13.250g of hydroxymethylpropionic acid, 28.157g of isophthalic acid, 29.247g of adipic acid, 25.634g of hexanediol, 24.300g of 1,4 cyclohexanedimethanol and stirring , Thermometer, nitrogen gas pipe, condenser and water separator in a four-port reactor, heat up to 140°C, stir, slowly heat up to 190°C, and keep it at 190°C for 1 hour. Start to measure the acid value. When the acid value drops to 46mgKOH / g resin, the xylene is removed in vacuum at about 100℃. After the reaction is completed, vacuum drying is carried out for 1-2 hours, the vacuum degree is ≥0.040Kpa, and the temperature is 50-80℃. , Namely the hydrophilic hydroxyl-terminated polyester (A).

[0074] (2) Add 28.356g of the above hydrophilic hydroxyl-terminated polyester (A), 4.258g 1,4 cyclohexanedimethanol, and 3.944g trimethylolpropane to the one equipped with a stirrer, thermometer, nitrogen gas pipe and condenser In a four-port reactor, vacuum pump water for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com