Automatic spiral hole-milling unit

A helical milling and automatic technology, which is applied to milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problem that manual tools cannot provide usability solutions, cannot meet the requirements of hole processing quality, and affect coaxiality and surface quality and other issues to achieve the effect of shortening the development cycle, shortening the research and development cycle, and reducing the cost of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

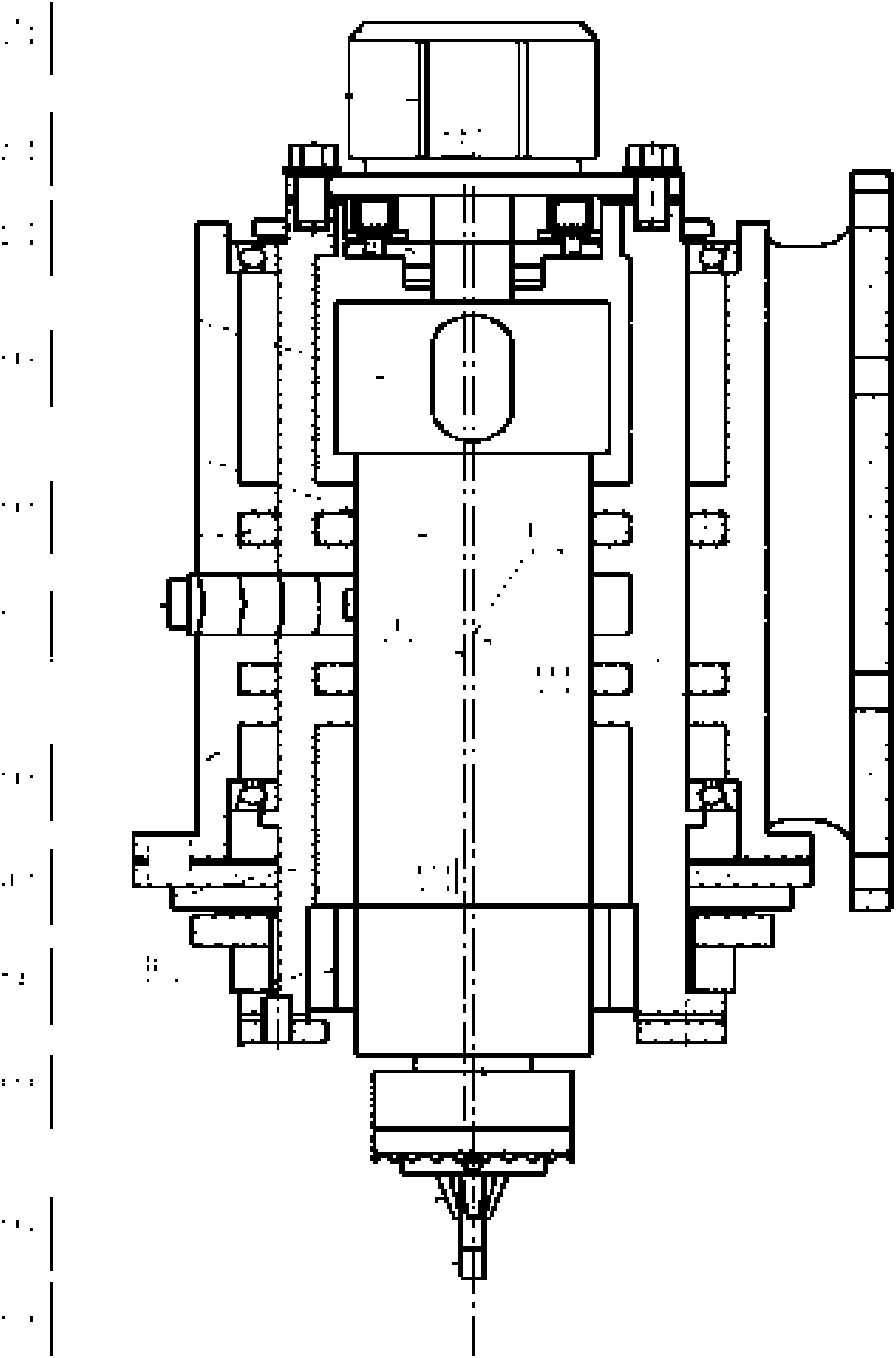

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

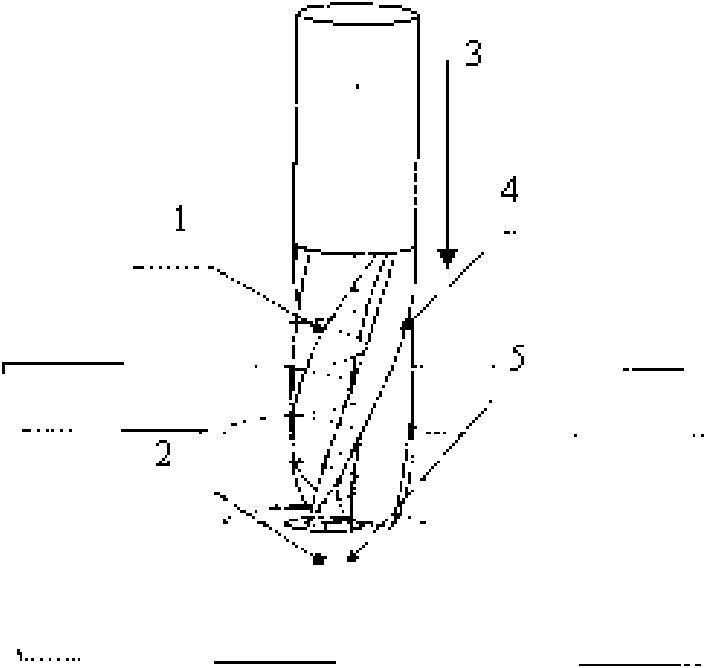

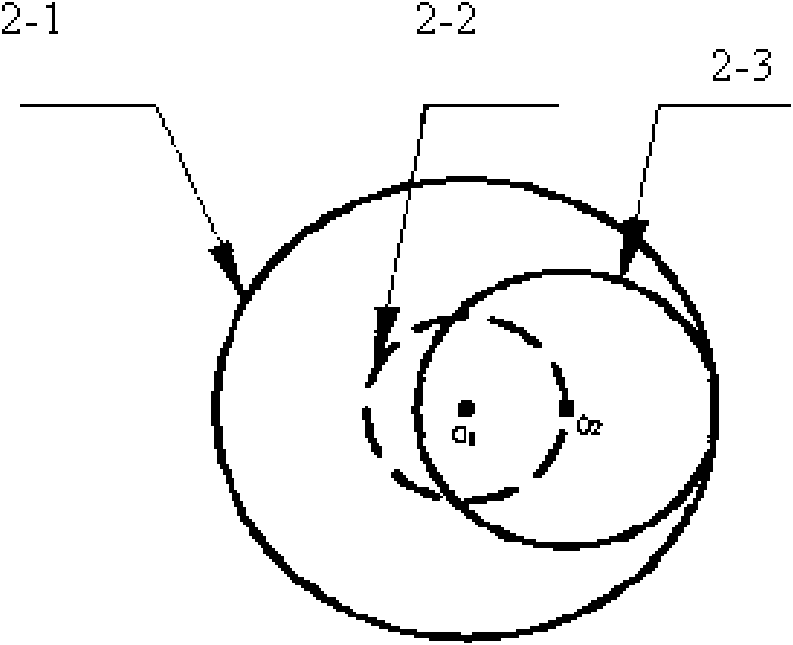

[0020] like Figure 1-2 As shown, the structure of the present invention is developed based on a helical milling process. Thus, the principle of helical milling is the essence of the present invention. like figure 1 As shown, where 1 refers to the movement track of the tool center, 2 refers to the centerline of the hole, 3 refers to the axial feed direction, 4 refers to the tool, and 5 refers to the centerline of the tool. The helical milling process is a "milling instead of drilling" process, which uses helical feed to realize cutting motion. The movement of the helical milling process is composed of the "autorotation" movement of the spindle, the "revolution" movement of the tool around the centerline of the hole, and the Z-direction feed of the spindle. These three movements are compounded. This special movement mode determines Advanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com