Controller of production clearance reactive power compensation device of power supply and distribution systems of small steel rolling workshop

A technology for power supply and distribution systems and workshops, which is applied in reactive power adjustment/elimination/compensation, flexible AC transmission systems, energy industry, etc. The effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

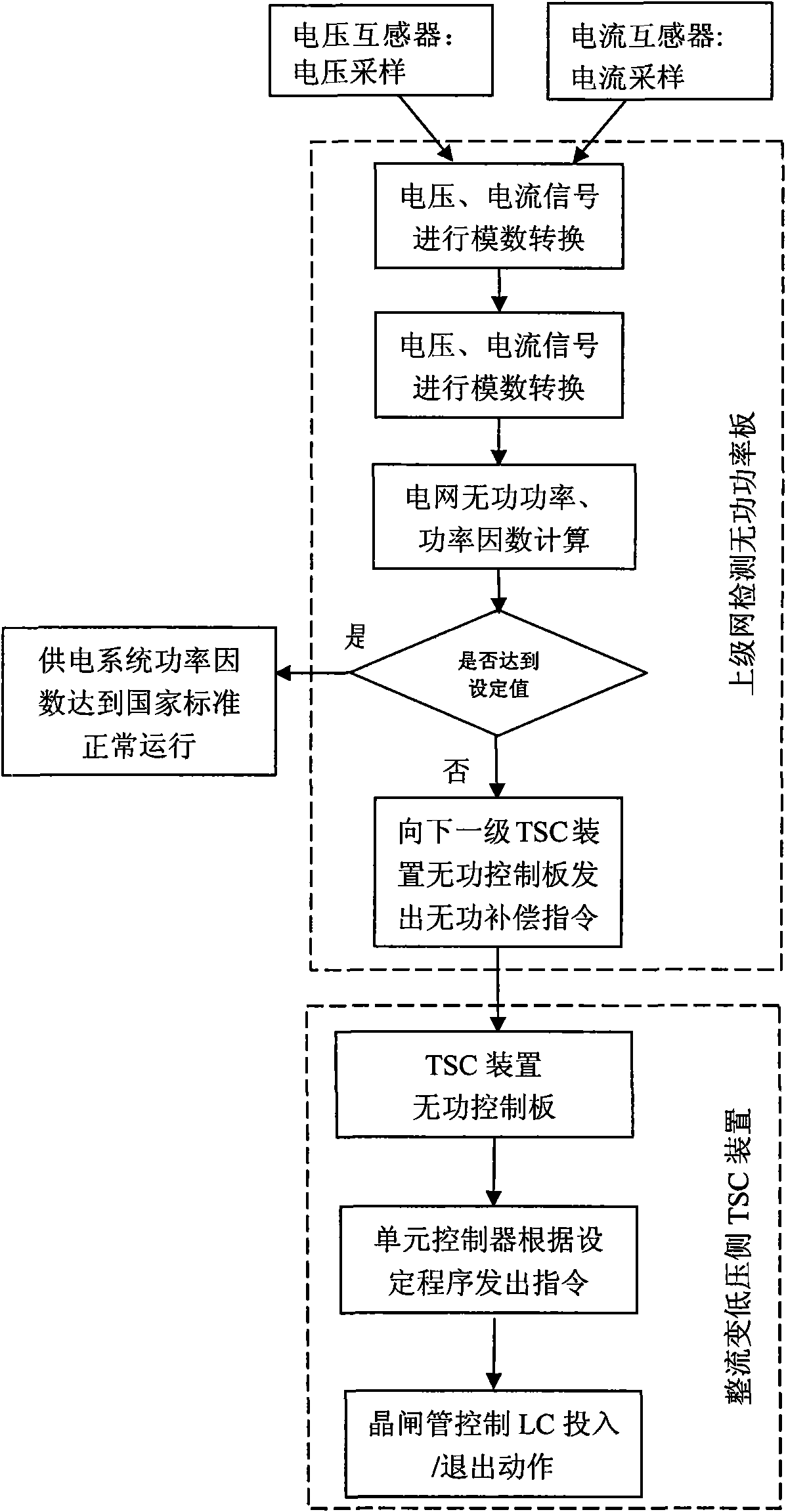

[0015] The main control unit of the high-voltage monitoring cabinet is composed of a reactive power control board. The reactive power control board mainly collects the voltage signals and current signals of the 10kV bus section I and section II buses respectively. Voltage detection: collect 10kV / 100V voltage signal of 10kV bus PT cabinet (potential transformer cabinet) for synchronous power supply detection.

[0016] Total current detection: collect the high-voltage B-phase current signal of the 10kV bus, and use the 5A current signal on the secondary side of the B-phase current transformer as the total current of the primary side of the transformer, that is, the total current of the 10kV bus.

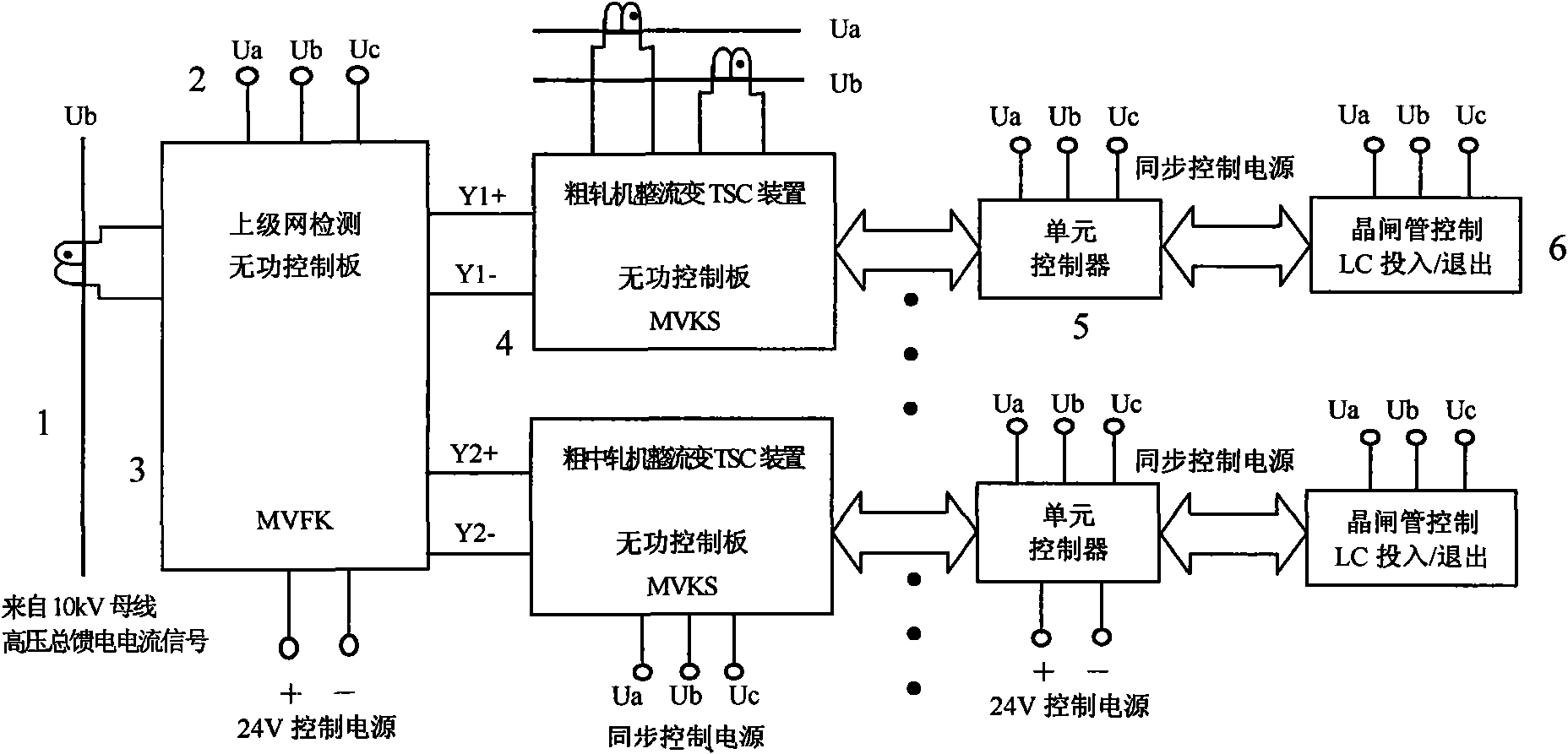

[0017] figure 1 The upper-level network detection reactive power board in the upper-level network analyzes and calculates the reactive power in the circuit through the collected 10kV bus current signal, and according to the preset reactive power switching sequence, according to the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com